Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  انګلیسي

انګلیسي  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

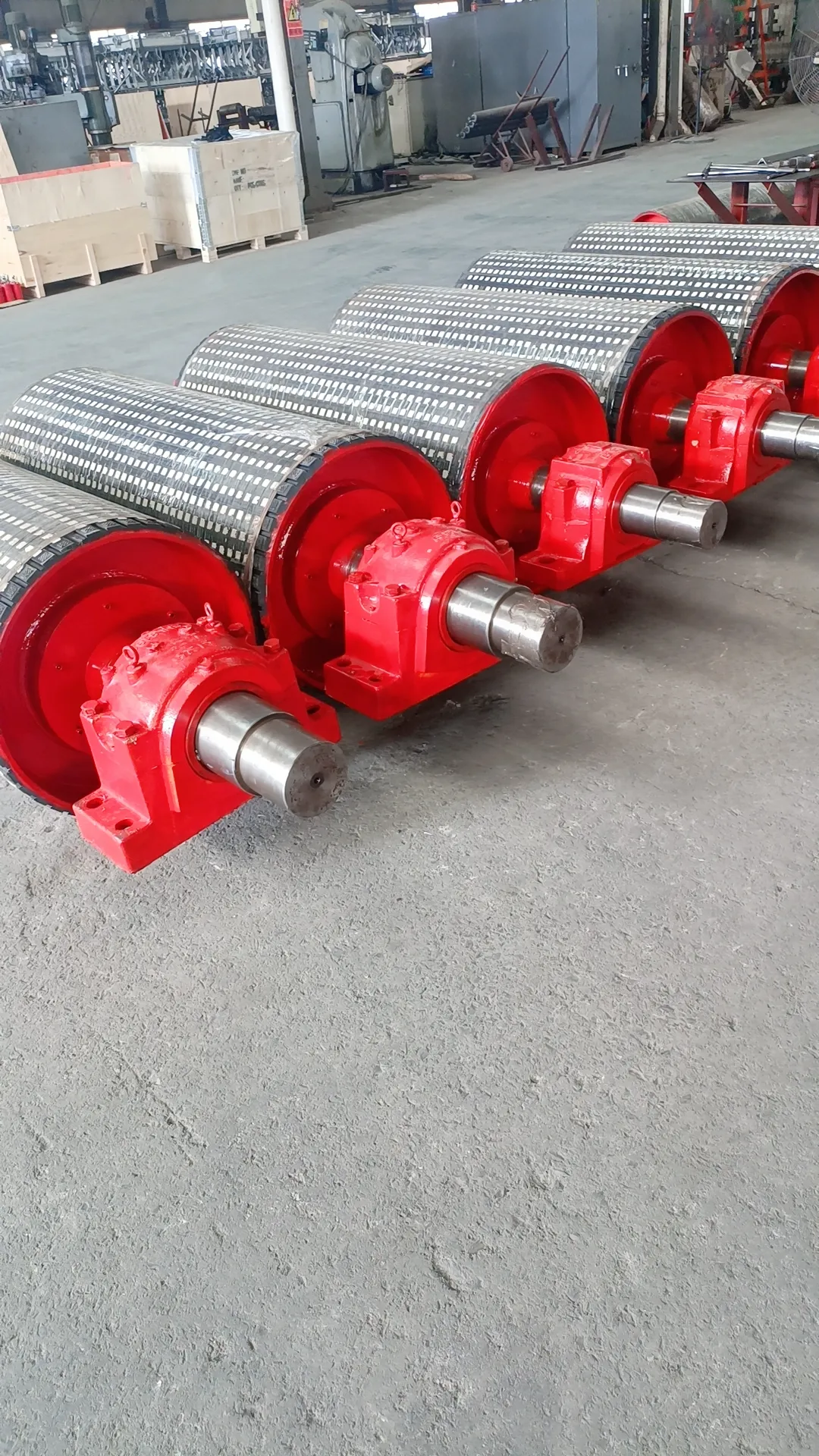

Zulu Belt Conveyor Pulley: The Heart of Your Conveyor System

The belt conveyor pulley is undeniably the heart of your conveyor system, playing the pivotal role of driving the conveyor belt. Positioned strategically at the head of the system, this powerful component ensures that the belt moves smoothly and consistently across the entire conveyor line. Without the belt conveyor pulley, the system would lack the force necessary to transport materials from point A to point B, essentially halting productivity.

The belt conveyor pulley is engineered to provide the right amount of tension, delivering continuous, smooth motion to the belt. Whether you're moving heavy-duty materials or delicate products, this pulley is designed to handle the pressure and keep the belt running without a hitch. Its primary function as the driving force behind the system makes it essential for maintaining optimal operation and efficiency.

Conveyor Pulley: A Must-Have for Effective Material Handling

When it comes to conveyor systems, the conveyor pulley is an indispensable component. It serves as the point of contact between the belt and the drive motor, transmitting the force needed to propel the belt forward. This simple yet effective part of your conveyor system helps maintain the correct tension while allowing the belt to move freely without unnecessary friction or wear.

The conveyor pulley is typically found at key locations throughout the system, but it’s the primary pulley at the head of the conveyor that ensures the smooth, consistent movement of materials. Its quality and durability are crucial for ensuring your conveyor runs at peak performance, so it's vital to invest in the right pulley for your specific needs. A high-quality conveyor pulley can drastically reduce maintenance costs by ensuring longevity and preventing damage to the conveyor belt.

Ceramic Lagging Pulley: Boosting Efficiency and Durability

To enhance the performance of your belt conveyor pulley, many industries turn to the ceramic lagging pulley. This advanced technology incorporates ceramic material onto the surface of the pulley, offering a significant improvement in traction and wear resistance. The ceramic lagging pulley provides better grip between the pulley and the conveyor belt, reducing slippage and improving the overall efficiency of your conveyor system.

One of the primary benefits of using a ceramic lagging pulley is its ability to extend the lifespan of your system by preventing premature belt wear caused by excessive friction. It’s especially useful in high-tension applications where the pulley is under constant stress. The increased grip and reduced slippage offered by the ceramic lagging pulley make it a fantastic solution for challenging environments, including those with heavy loads and high-speed conveyor systems.

Conveyor Pulley Lagging: The Secret to Enhanced Performance

Incorporating conveyor pulley lagging into your system can work wonders for improving both the performance and lifespan of your conveyor. This lagging is typically applied to the surface of the pulley to prevent direct contact between the pulley and the belt, minimizing wear and tear. Not only does conveyor pulley lagging enhance the lifespan of your system, but it also increases the coefficient of friction, improving the grip between the belt and the pulley.

Conveyor pulley lagging is available in a variety of materials, such as rubber and ceramic, each offering its unique set of benefits. Rubber lagging helps absorb shock and reduce noise, while ceramic lagging boosts traction and enhances resistance to wear and extreme conditions. By selecting the appropriate conveyor pulley lagging, you ensure that your system runs efficiently, with minimized downtime and maintenance.

The Importance of the Primary Pulley in Your Conveyor System

The primary pulley is more than just a part of the conveyor system—it’s the backbone of the entire operation. Here’s why it’s absolutely essential:

-

Drives the Conveyor Belt: Located at the head of the system, the primary pulleyis the key driver, making sure the belt moves smoothly and efficiently. Without it, the system would grind to a halt.

-

Enhances System Efficiency: Whether you're using a standard belt conveyor pulleyor an advanced ceramic lagging pulley, these pulleys ensure that the belt operates at its optimal speed and tension, reducing friction and improving efficiency.

-

Increases Durability: High-quality conveyor pulleysand lagging protect the belt from excessive wear and tear, ensuring that the entire system remains in top condition for longer.

-

Prevents Slippage: Using ceramic lagging pulleysand conveyor pulley lagging can significantly improve the grip between the pulley and the belt, reducing slippage and ensuring consistent, reliable performance.

Don't let your conveyor system fall short on performance. Invest in top-quality belt conveyor pulleys, ceramic lagging pulleys, and conveyor pulley lagging to enhance efficiency, prevent premature wear, and keep your system running smoothly. Check out our range of premium conveyor pulleys designed to meet your specific needs and elevate your operations. Shop now for the best products on the market!

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysخبرونهJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsخبرونهJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesخبرونهJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysخبرونهJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerخبرونهJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersخبرونهJul.22,2025