Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  angle

angle  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Friksyon Aliyman Idler

Deskripsyon detaye

Deskripsyon detaye

Friction Aligning Idlers has a strong ability to protect the conveyor belt from damage and off-line operation. When the conveyor belt runs offline, the side to which the conveyor belt runs will increase the friction on that side. Under the action of friction, the side with greater friction will swing in the direction of the conveyor belt movement. The automatic swing function brings the conveyor belt back to the center line.

Spesifikasyon pwodwi

Spesifikasyon pwodwi

|

Pwodwi detay |

Deskripsyon |

Lòd Sèvis |

|

Non pwodwi: friksyon aliyman Idler |

Materyèl ankadreman: Angle Steel 、 Chanèl Steel 、 Steel Tiyo |

Minimòm lòd: 1 moso |

|

Non orijin: pwovens Hebei, Lachin |

Materyèl estanda: Q235B, Q235A |

Pri: negosyab |

|

Non mak: AOHUA |

Epesè miray: 6-12mm oswa selon lòd |

Anbalaj: bwat plywood san fumigasyon, ankadreman fè, palèt |

|

Estanda: CEMA, ISO, DIN, JIS, DTII |

Soudi: Melanje gaz Arc soude |

Tan livrezon: 10-15 jou |

|

Lajè senti: 400-2400mm |

Metòd soude: robo soude |

Tèm Peman: TT, LC |

|

Tan lavi: 30000 èdtan |

Koulè: Nwa 、 Wouj 、 Vèt 、 Ble 、 oswa selon lòd |

Pò anbakman: Tianjin Xingang, Shanghai, Qingdao |

|

Ranje epesè miray roulo: 2.5 ~ 6mm |

Pwosesis kouch: flite poud elektwostatik 、 penti 、 cho-dip-galvanize |

|

|

Dyamèt Ranje roulo: 48-219mm |

Aplikasyon: min chabon, plant siman, kraze, plant elektrik, moulen asye, metaliji, karyè, enprime, endistri resiklaj ak lòt ekipman transpò |

|

|

Dyamèt ranje aks: 17-60mm |

Sèvis anvan ak apre: sipò sou entènèt, sipò teknik videyo |

|

|

Kote yo pote mak: HRB、ZWZ、LYC、SKF、FAG、NSK |

||

Pwodwi Paramèt

Pwodwi Paramèt

|

Paramèt pou pote friksyon aliyman Idler |

|||||||||||||

|

Lajè senti (mm) |

Woulo (mm) |

Woulo friksyon (mm) |

Gwo dimansyon (mm) |

||||||||||

|

D1 |

L1 |

Bearing Type |

D2 |

L2 |

A |

E |

H |

H1 |

H2 |

P |

Q |

d |

|

|

500 |

89 |

200 |

6204 |

170 |

230 |

740 |

800 |

220 |

135.5 |

350 |

170 |

130 |

M12 |

|

650 |

89 |

250 |

6204 |

170 |

280 |

890 |

950 |

235 |

135.5 |

379 |

170 |

130 |

M12 |

|

108 |

250 |

6205 |

210 |

294 |

265 |

145 |

414 |

||||||

|

800 |

89 |

315 |

6204 |

170 |

323 |

1090 |

1150 |

245 |

135.5 |

403 |

170 |

130 |

M12 |

|

108 |

6205 |

210 |

342 |

270 |

146 |

442 |

|||||||

|

133 |

6305 |

240 |

348 |

305 |

159.5 |

471 |

|||||||

|

1000 |

108 |

380 |

6205 |

210 |

405 |

1290 |

1350 |

300 |

159 |

493 |

220 |

170 |

M16 |

|

133 |

6305 |

240 |

412 |

325 |

173.5 |

524 |

|||||||

|

159 |

6306 |

270 |

429 |

370 |

190.5 |

564 |

|||||||

|

1200 |

108 |

465 |

6205 |

210 |

465 |

1540 |

1600 |

355 |

176 |

544 |

260 |

200 |

M16 |

|

133 |

6305 |

240 |

473 |

360 |

190.5 |

575 |

|||||||

|

159 |

6306 |

270 |

494 |

390 |

207.5 |

618 |

|||||||

|

1400 |

108 |

530 |

6205 |

210 |

533 |

1740 |

1810 |

350 |

184 |

591 |

280 |

220 |

M16 |

|

133 |

6305 |

240 |

540 |

380 |

198.5 |

622 |

|||||||

|

159 |

6306 |

270 |

553 |

410 |

215.5 |

660 |

|||||||

|

Paramèt pou retounen friksyon aliyman Idler |

|||||||||||

|

Lajè senti (mm) |

Woulo friksyon (mm) |

Gwo dimansyon (mm) |

|||||||||

|

D1 |

L1 |

D2 |

Bearing Type |

A |

E |

H |

H1 |

P |

Q |

d |

|

|

500 |

89 |

323 |

170 |

6204 |

740 |

840 |

100 |

334 |

140 |

90 |

M12 |

|

650 |

89 |

398 |

170 |

6204 |

890 |

990 |

93.5 |

313.5 |

140 |

90 |

M12 |

|

108 |

210 |

6205 |

109.5 |

357.5 |

|||||||

|

800 |

89 |

473 |

170 |

6204 |

1090 |

1190 |

144.5 |

367.5 |

140 |

90 |

M12 |

|

108 |

210 |

6205 |

154 |

396 |

|||||||

|

133 |

240 |

6305 |

166.5 |

427.5 |

|||||||

|

1000 |

108 |

590 |

210 |

6205 |

1290 |

1390 |

164 |

411 |

160 |

90 |

M16 |

|

133 |

240 |

6305 |

176.5 |

443.5 |

|||||||

|

159 |

599 |

270 |

6306 |

189.5 |

475.5 |

||||||

|

1200 |

108 |

690 |

210 |

6205 |

1540 |

1640 |

174 |

441 |

160 |

90 |

M16 |

|

133 |

240 |

6305 |

186.5 |

473.5 |

|||||||

|

159 |

699 |

270 |

6306 |

199.5 |

505.5 |

||||||

|

1400 |

108 |

790 |

210 |

6205 |

1740 |

1840 |

184 |

451 |

180 |

120 |

M16 |

|

133 |

240 |

6305 |

196.5 |

483.5 |

|||||||

|

159 |

799 |

270 |

6306 |

209.5 |

515.5 |

||||||

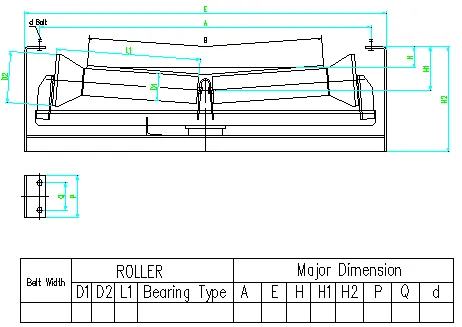

Diagrammatic Drawings and Parameters for Carrying Friction Aligning Idler:

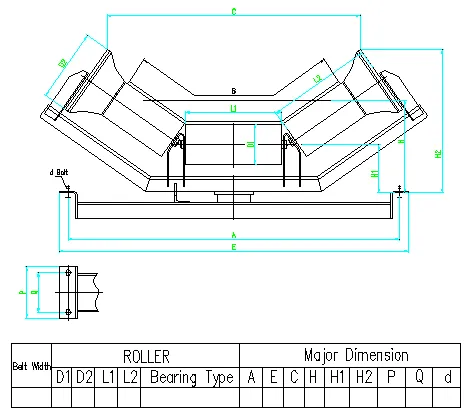

Desen dyagram ak paramèt pou retounen friksyon aliyman Idler: