Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Exploring Various Elements of Conveyor Systems for Enhanced Efficiency and Performance

Understanding Conveyor Components The Backbone of Material Handling Systems

In the realm of material handling and logistics, conveyor systems play a pivotal role in facilitating efficient movement, sorting, and processing of goods. Essential to these conveyors are various components that work harmoniously to ensure seamless operations. In this article, we will explore the key conveyor components, their functions, and their significance in enhancing productivity across multiple industries.

1. Belt

The conveyor belt is arguably the most recognizable part of any conveyor system. It is a continuous loop of material, typically made from rubber, fabric, or metal, that transports products from one location to another. The choice of belt material depends on the type of goods being transported and the environmental conditions. For instance, a belt designed for heavy-duty applications may use reinforced rubber to withstand abrasion, while a lighter fabric belt may suffice for less demanding tasks.

2. Rollers

Rollers are crucial for reducing friction and supporting the weight of the conveyor load. They are positioned beneath the conveyor belt along its length, allowing it to move smoothly over them. Rollers come in various types, including return rollers, impact rollers, and drive rollers, each serving a specific function. For example, drive rollers are equipped with a motor to propel the belt, while return rollers manage the belt's return journey to maintain tension and alignment.

3. Frame

The frame of a conveyor system is its structural foundation, providing support and stability. Typically made from steel or aluminum, the frame determines the conveyor’s overall strength and durability. It is designed to withstand the weight of the material being transported and other operational stresses. The frame's design also impacts the conveyor's footprint, making it essential for optimizing space in a facility.

4. Drive System

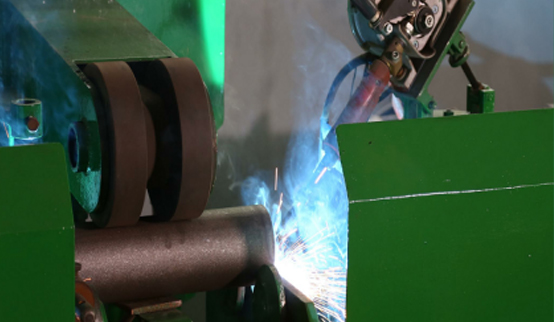

conveyor component

The drive system is responsible for powering the conveyor belt. It typically consists of an electric motor, gearbox, and a coupling mechanism. The motor generates the necessary torque to move the belt at the desired speed. Variability in speed is a critical aspect that enhances the flexibility of conveyor systems, allowing them to adapt to different operational requirements. In some advanced systems, variable frequency drives (VFDs) can be employed to control the speed and torque, further improving energy efficiency.

5. Idlers

Idlers are positioned along the length of the conveyor to support the belt and maintain its alignment. They help in managing belt tension, which is crucial for efficient operation. Properly functioning idlers prevent the belt from sagging and reduce wear and tear on the belt and other components. Depending on the application, idlers can be either fixed or adjustable to accommodate varying loads.

6. Controls and Sensors

Modern conveyor systems are often equipped with sophisticated control systems and sensors. These components enhance the automation and efficiency of the system. For example, sensors can detect the position of materials on the conveyor and adjust the speed or direction accordingly. Control panels enable operators to monitor system performance, diagnose faults, and make real-time adjustments, ensuring optimal functionality.

7. Safety Features

Safety is paramount in any industrial setting, and conveyor systems are no exception. Various safety components, such as emergency stop switches, guards, and safety sensors, are integrated into the conveyor design to protect operators and maintenance personnel. These features help mitigate risks associated with moving parts and potential hazards, ensuring compliance with industry safety standards.

Conclusion

Conveyor components are the unsung heroes of material handling, making it possible for industries to operate efficiently and effectively. Understanding the roles of each component—from belts and rollers to drive systems and safety features—is essential for optimizing conveyor performance. As technology continues to evolve, so too will the design and functionality of conveyor systems, further enhancing their role in streamlining operations across various sectors. Investing in high-quality components and regular maintenance is crucial for any business looking to harness the full potential of conveyor systems, ultimately leading to increased productivity and profitability.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025