Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Adjusting Conveyor Belt Scrapers for Optimal Performance and Efficiency

Understanding Conveyor Belt Scraper Adjustment

Conveyor belts are integral components in numerous industrial applications, facilitating the movement of goods and materials across various processes. However, ensuring the efficient functionality of a conveyor belt system requires regular maintenance and adjustments, particularly concerning the conveyor belt scraper. The scraper plays a critical role in removing excess material, debris, and contaminants from the surface of the conveyor belt, thus preventing product contamination and ensuring optimal performance. This article delves into the importance of conveyor belt scraper adjustment and provides guidelines for effective maintenance.

The Importance of Conveyor Belt Scrapers

Conveyor belt scrapers are devices fixed to the belt to prevent the build-up of materials on its surface. This build-up can lead to several operational challenges. It can cause significant wear and tear on the belt, reducing its lifespan and increasing maintenance costs. Furthermore, material accumulation can lead to product contamination, which is particularly crucial in industries like food processing and pharmaceuticals, where hygiene standards are paramount.

Moreover, a properly adjusted scraper enhances the overall efficiency of the conveyor system. It helps maintain a consistent flow of materials, reduces energy consumption, and minimizes downtime due to blockages or belt malfunction. Therefore, regular inspection and adjustment of the scrapers are essential for the ongoing effectiveness of any conveyor system.

Signs of Misalignment or Deterioration

Identifying when a conveyor belt scraper needs adjustment is critical. Several signs can indicate that your scraper is misaligned or worn out

1. Material Build-Up If you notice an accumulation of materials on the conveyor belt after the scraper, it may indicate that the scraper is not making proper contact or is worn down.

2. Noise Excess noise when the conveyor is in operation can also suggest that the scraper is misaligned, as it could be scraping against the belt inappropriately.

3. Belt Damage Visible wear or damage to the belt might indicate a problem with the scraper. If the scraper is too tight, it may cause unnecessary friction, leading to belt deterioration.

conveyor belt scraper adjustment

Guidelines for Proper Scraper Adjustment

To ensure the longevity and efficiency of your conveyor system, follow these guidelines for checking and adjusting your belt scraper

1. Regular Inspections Schedule routine inspections of the scrapers. Check for signs of wear, misalignment, or damage. Regular checks will help you catch issues before they become significant problems.

2. Correct Alignment Ensure that the scraper is aligned correctly with the belt. It should make consistent contact with the belt surface without excessive pressure. Adjustment can often be made with simple tools, but be sure to follow manufacturer instructions or guidelines for specific design setups.

3. Adjusting Scraper Position Many scraper systems allow for easy height and angle adjustments. Ensuring the correct angle can affect how efficiently the scraper can remove material without damaging the belt.

4. Material Consideration Keep in mind the type of materials you are transporting. Different materials may necessitate different scraper designs or adjustments. For example, sticky materials may require more frequent adjustments compared to dry, loose materials.

5. Regular Maintenance Much like any mechanical component, scrapers require maintenance. Replace worn-out components immediately to maintain maximum efficiency.

Conclusion

In conclusion, conveyor belt scraper adjustment is a vital aspect of maintaining an efficient and reliable conveyor system. Properly functioning scrapers not only enhance operational efficiency but also help extend the life of the conveyor belt and conserve resources. By routinely inspecting and adjusting the scrapers, industries can minimize downtime and ensure a smooth flow of materials. Investing time and effort into scraper maintenance will undoubtedly yield significant long-term benefits, including reduced repair costs and enhanced productivity in various applications.

-

Wing Pulley Conveyor for Conveyor Belt MaintenanceNewsJun.16,2025

-

Self Cleaning Spiral Idler for Conveyor DesignNewsJun.16,2025

-

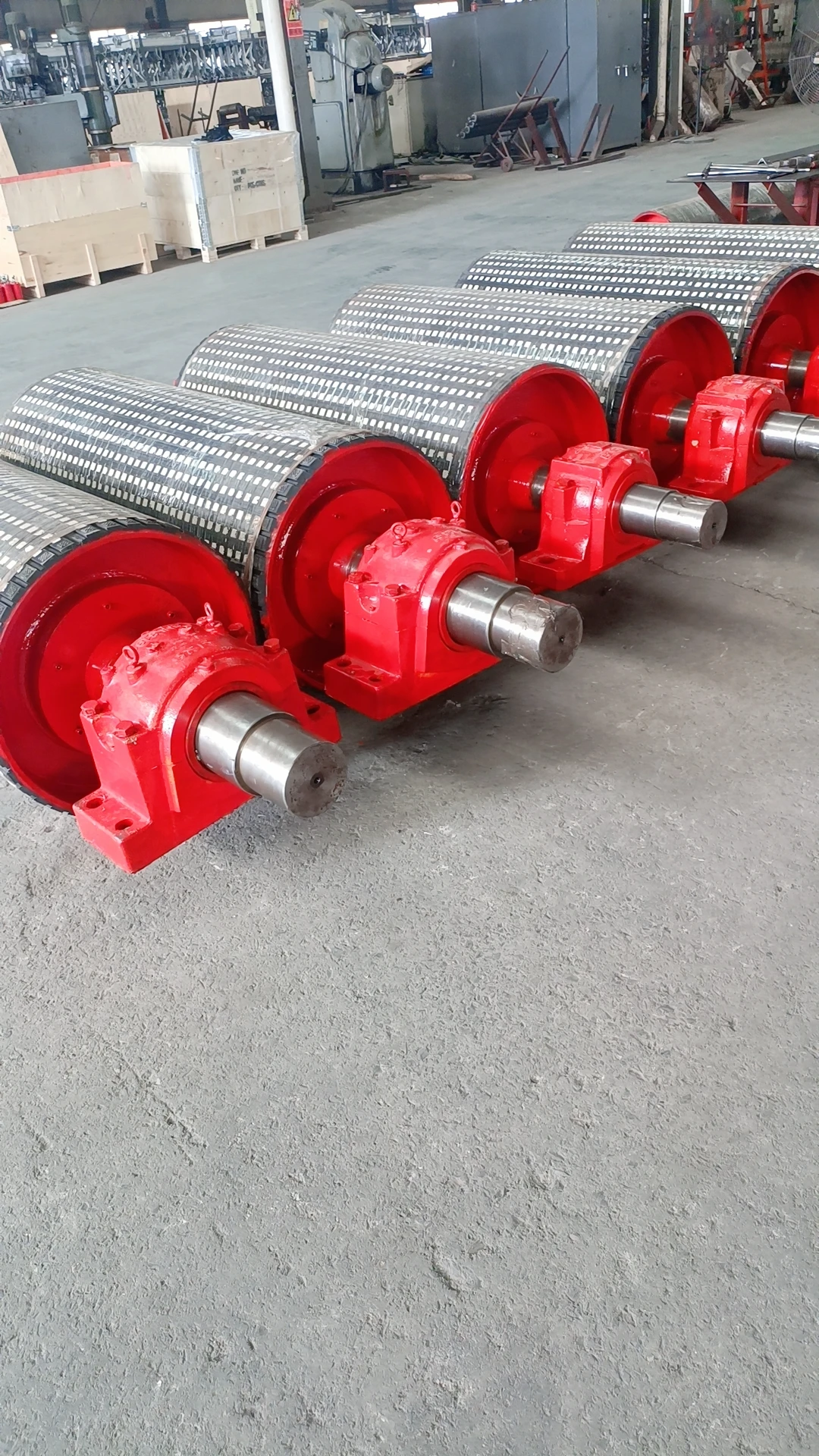

Pulley Lagging for Conveyor Belt AlignmentNewsJun.16,2025

-

Impact Idlers Used in Belt Conveyor for PerformanceNewsJun.16,2025

-

Ceramic Lagging Conveyor Pulley for Conveyor Belt SystemsNewsJun.16,2025

-

Belt Conveyor Idler for Heavy-Duty ApplicationsNewsJun.16,2025