Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Čvn . 27, 2024 00:53

Back to list

Conveyor Guide Rollers Overview, Selection, & Maintenance

Conveyor Guide Rollers Essential Components for Smooth Material Handling

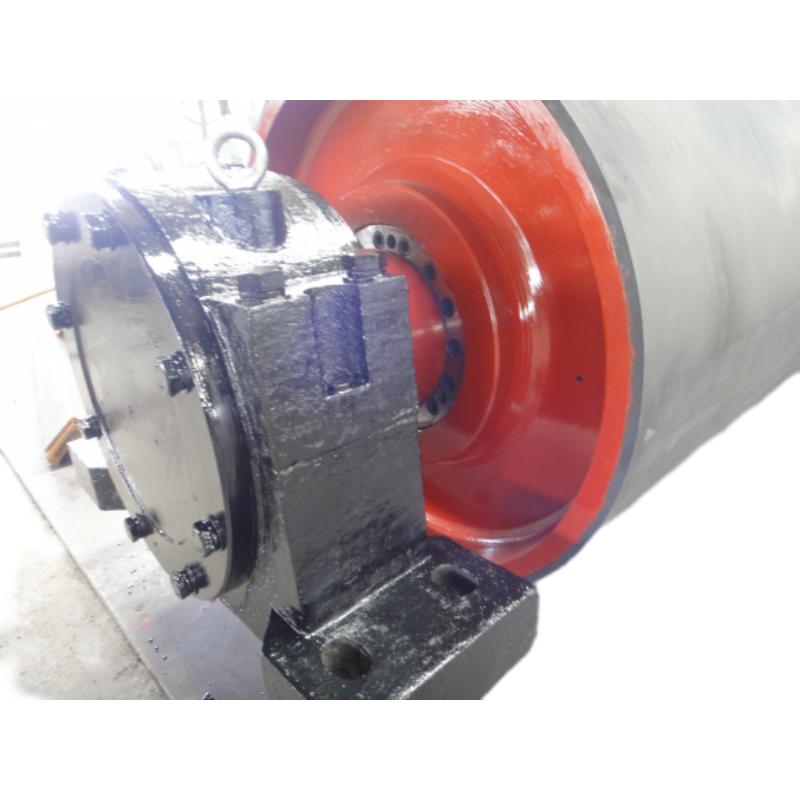

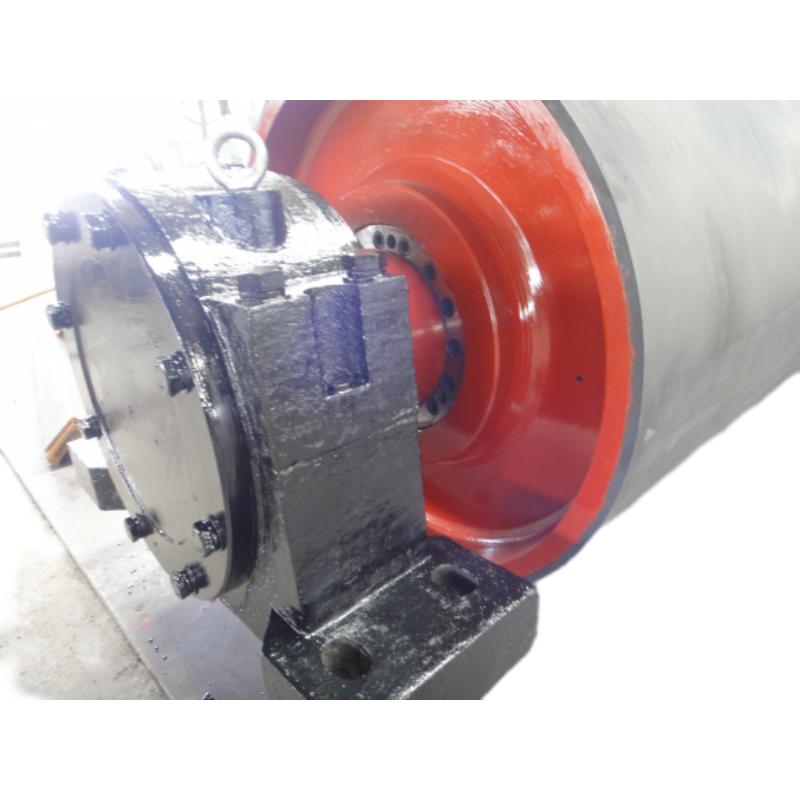

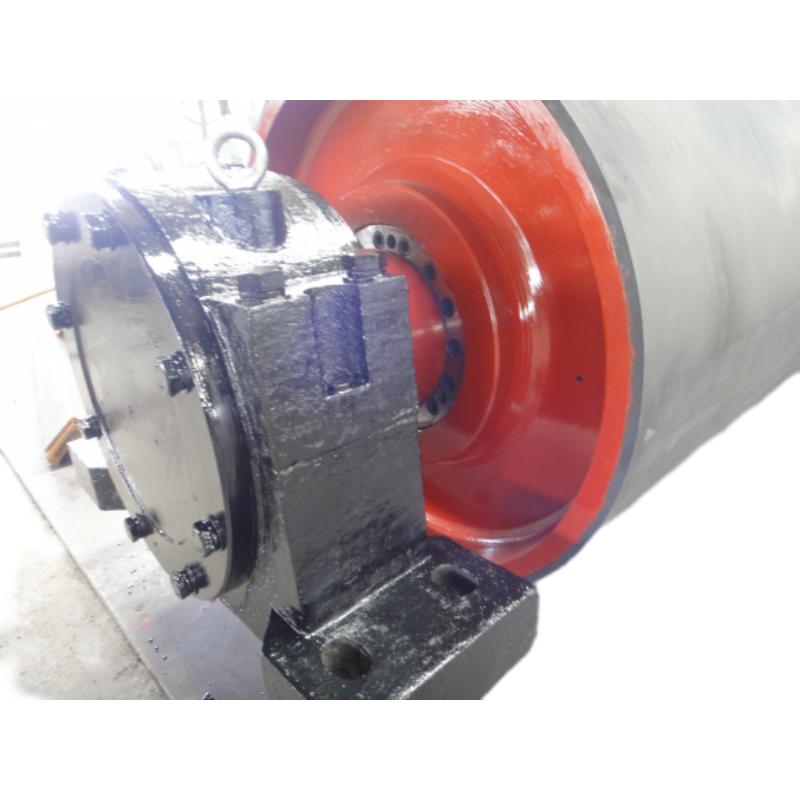

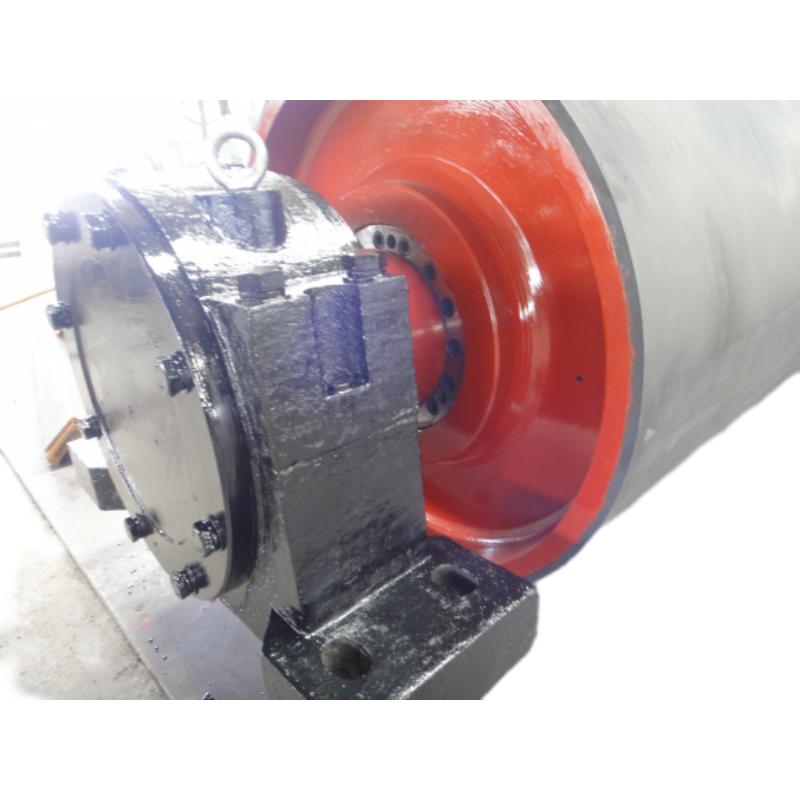

In the world of material handling, conveyor systems play a crucial role in transporting goods efficiently and effectively. These systems consist of various components, including conveyor belts, rollers, and drives, all working together to ensure that materials are moved smoothly and without delays. One such critical component is the conveyor guide roller.

A conveyor guide roller, also known as a tracking roller or idler roller, is designed to keep the conveyor belt properly aligned and on track. It does this by applying gentle pressure to the side of the belt, preventing it from veering off course. This is particularly important in applications where the belt is carrying heavy loads or moving at high speeds, as even small deviations can lead to misalignment and potential damage to the system.

Guide rollers come in a variety of sizes and shapes, with different materials and coatings to suit specific applications. Some are made from durable materials like steel or aluminum, while others may be coated with rubber or plastic to provide additional grip and reduce noise. The shape of the roller can also vary, with some being cylindrical or tapered to better fit the contours of the conveyor belt.

One of the key benefits of using conveyor guide rollers is their ability to improve the overall efficiency of the material handling system

One of the key benefits of using conveyor guide rollers is their ability to improve the overall efficiency of the material handling system One of the key benefits of using conveyor guide rollers is their ability to improve the overall efficiency of the material handling system

One of the key benefits of using conveyor guide rollers is their ability to improve the overall efficiency of the material handling system

One of the key benefits of using conveyor guide rollers is their ability to improve the overall efficiency of the material handling system

One of the key benefits of using conveyor guide rollers is their ability to improve the overall efficiency of the material handling system conveyor guide rollers. When belts are properly aligned, they can run more smoothly and with less resistance, which means less energy is required to move materials. This can lead to significant cost savings over time, as well as reduced wear and tear on the system itself.

Another advantage of guide rollers is their versatility. They can be used in a wide range of industries, from manufacturing and logistics to food processing and packaging. Whether you need to transport heavy loads over long distances or handle delicate products with precision, conveyor guide rollers can be customized to meet your specific needs.

In conclusion, conveyor guide rollers are essential components of any material handling system. By keeping belts properly aligned and on track, these rollers help to ensure smooth and efficient operation, reducing costs and improving productivity. With their durability, versatility, and ability to improve overall system efficiency, guide rollers are a must-have for anyone involved in material handling.

conveyor guide rollers. When belts are properly aligned, they can run more smoothly and with less resistance, which means less energy is required to move materials. This can lead to significant cost savings over time, as well as reduced wear and tear on the system itself.

Another advantage of guide rollers is their versatility. They can be used in a wide range of industries, from manufacturing and logistics to food processing and packaging. Whether you need to transport heavy loads over long distances or handle delicate products with precision, conveyor guide rollers can be customized to meet your specific needs.

In conclusion, conveyor guide rollers are essential components of any material handling system. By keeping belts properly aligned and on track, these rollers help to ensure smooth and efficient operation, reducing costs and improving productivity. With their durability, versatility, and ability to improve overall system efficiency, guide rollers are a must-have for anyone involved in material handling.

One of the key benefits of using conveyor guide rollers is their ability to improve the overall efficiency of the material handling system

One of the key benefits of using conveyor guide rollers is their ability to improve the overall efficiency of the material handling system

One of the key benefits of using conveyor guide rollers is their ability to improve the overall efficiency of the material handling system

One of the key benefits of using conveyor guide rollers is their ability to improve the overall efficiency of the material handling system conveyor guide rollers. When belts are properly aligned, they can run more smoothly and with less resistance, which means less energy is required to move materials. This can lead to significant cost savings over time, as well as reduced wear and tear on the system itself.

Another advantage of guide rollers is their versatility. They can be used in a wide range of industries, from manufacturing and logistics to food processing and packaging. Whether you need to transport heavy loads over long distances or handle delicate products with precision, conveyor guide rollers can be customized to meet your specific needs.

In conclusion, conveyor guide rollers are essential components of any material handling system. By keeping belts properly aligned and on track, these rollers help to ensure smooth and efficient operation, reducing costs and improving productivity. With their durability, versatility, and ability to improve overall system efficiency, guide rollers are a must-have for anyone involved in material handling.

conveyor guide rollers. When belts are properly aligned, they can run more smoothly and with less resistance, which means less energy is required to move materials. This can lead to significant cost savings over time, as well as reduced wear and tear on the system itself.

Another advantage of guide rollers is their versatility. They can be used in a wide range of industries, from manufacturing and logistics to food processing and packaging. Whether you need to transport heavy loads over long distances or handle delicate products with precision, conveyor guide rollers can be customized to meet your specific needs.

In conclusion, conveyor guide rollers are essential components of any material handling system. By keeping belts properly aligned and on track, these rollers help to ensure smooth and efficient operation, reducing costs and improving productivity. With their durability, versatility, and ability to improve overall system efficiency, guide rollers are a must-have for anyone involved in material handling. Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS