Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 14, 2025 01:36

Back to list

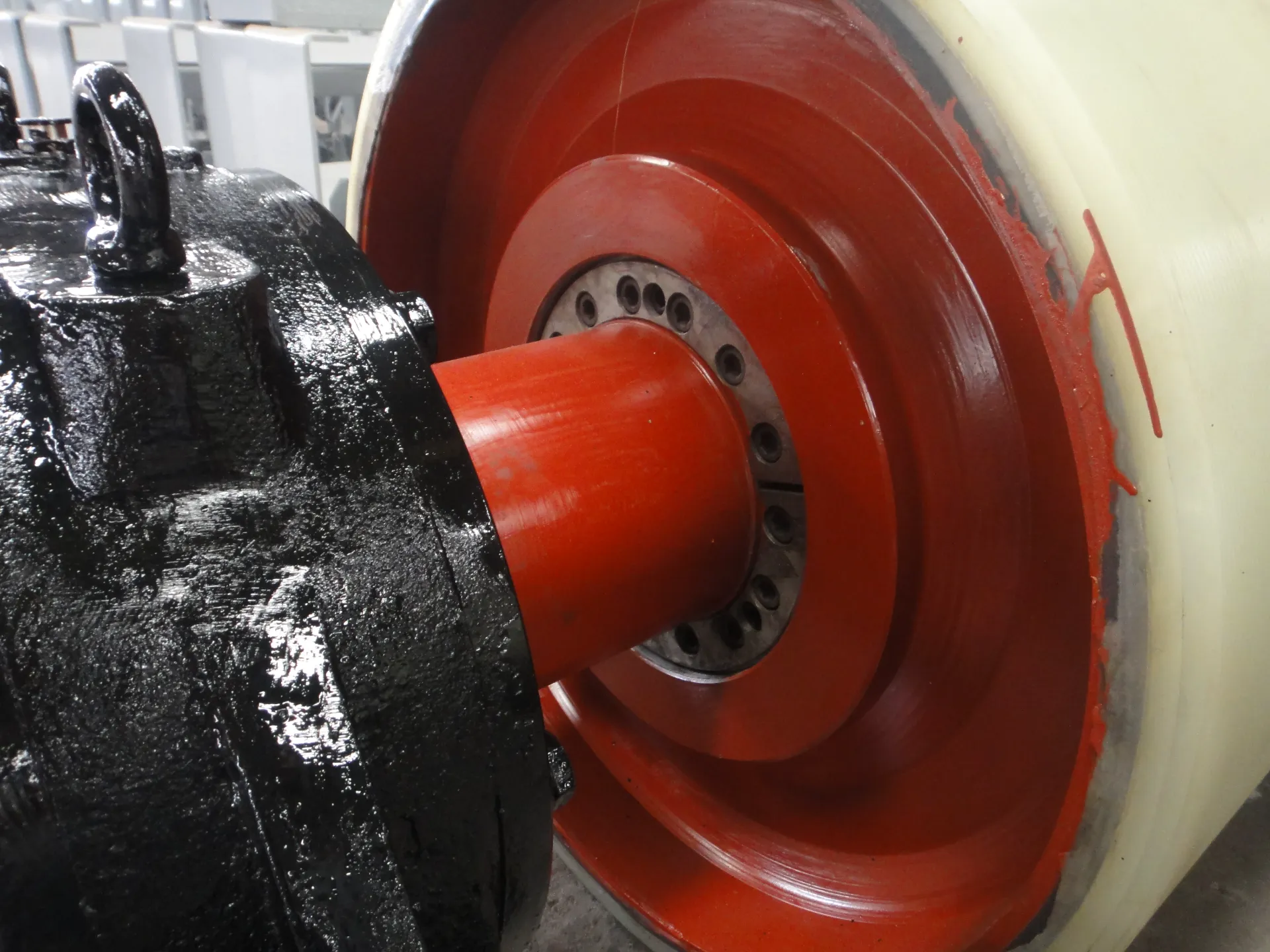

return idler bracket

Return idler brackets play a fundamental role in various industrial applications, particularly in conveyor systems that underline the efficiency of many manufacturing processes. Leveraging years of expertise in industrial engineering and machinery maintenance, I will delve into the intricacies of return idler brackets, highlighting their significance and providing insights drawn from real-world experiences.

When discussing the trustworthiness of return idler brackets, it is vital to address the maintenance aspect. Regular inspections and preventive maintenance schedules are crucial. A preventative approach involves routinely checking the bracket for signs of wear, corrosion, or misalignment. If an issue is detected, prompt corrective actions should be taken to prevent further complications. Such practices not only enhance the lifespan of the return idler brackets but also improve the overall efficiency and safety of the conveyor system. For optimal performance, innovations in return idler bracket designs, such as adjustable brackets or self-cleaning features, are becoming increasingly prevalent. These advancements signify a shift in market trends towards smarter and more adaptable components. Companies are investing in research and development to enhance the capabilities of standard return idler brackets, aiming for solutions that cater to a diverse range of industrial applications. Reflecting on past experiences, collaboration between the engineering teams and the end-users is vital to identify specific needs and constraints of the operation. Such partnerships facilitate customized solutions that align with the operational goals and strategic direction of the business. By prioritizing experience and expertise, companies can ensure that the return idler bracket becomes a pivotal component in raising the efficiency and reliability of their conveyor systems. In conclusion, return idler brackets, though often overlooked, are indispensable in maintaining the effectiveness and efficiency of conveyor systems. By prioritizing expert design, authoritative manufacturing standards, and trustworthy maintenance practices, industries can significantly diminish operational risks and enhance productivity. Those companies that invest in high-quality idler brackets and uphold exemplary operational standards will undoubtedly position themselves as leaders in industrial innovation and reliability.

When discussing the trustworthiness of return idler brackets, it is vital to address the maintenance aspect. Regular inspections and preventive maintenance schedules are crucial. A preventative approach involves routinely checking the bracket for signs of wear, corrosion, or misalignment. If an issue is detected, prompt corrective actions should be taken to prevent further complications. Such practices not only enhance the lifespan of the return idler brackets but also improve the overall efficiency and safety of the conveyor system. For optimal performance, innovations in return idler bracket designs, such as adjustable brackets or self-cleaning features, are becoming increasingly prevalent. These advancements signify a shift in market trends towards smarter and more adaptable components. Companies are investing in research and development to enhance the capabilities of standard return idler brackets, aiming for solutions that cater to a diverse range of industrial applications. Reflecting on past experiences, collaboration between the engineering teams and the end-users is vital to identify specific needs and constraints of the operation. Such partnerships facilitate customized solutions that align with the operational goals and strategic direction of the business. By prioritizing experience and expertise, companies can ensure that the return idler bracket becomes a pivotal component in raising the efficiency and reliability of their conveyor systems. In conclusion, return idler brackets, though often overlooked, are indispensable in maintaining the effectiveness and efficiency of conveyor systems. By prioritizing expert design, authoritative manufacturing standards, and trustworthy maintenance practices, industries can significantly diminish operational risks and enhance productivity. Those companies that invest in high-quality idler brackets and uphold exemplary operational standards will undoubtedly position themselves as leaders in industrial innovation and reliability.

Next:

Latest news

-

The Unrivaled Performance of Polyurethane Pulleys in Industrial ApplicationsNewsAug.25,2025

-

The Critical Role of Drum Lagging in Conveyor SystemsNewsAug.25,2025

-

Navigating Industrial Efficiency: The Critical Role of Conveyor PulleysNewsAug.25,2025

-

InIntroduction to Advanced Pulley Lagging SolutionsNewsAug.25,2025

-

Industry Trends in Pulley Lagging TechnologyNewsAug.25,2025

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

OUR PRODUCTS