Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 15, 2025 19:41

Back to list

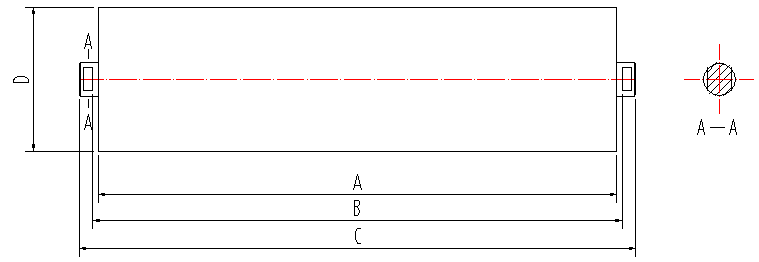

mining conveyor rollers

In the realm of industrial operations, where the atmosphere is often defined by the constant hum of machinery and the relentless output of raw materials, mining conveyor rollers play an indispensable role. Their importance is underscored by their contribution to efficiency, cost-saving, and operational longevity in mining operations. This article delves into the nuanced specifics of mining conveyor rollers, reflecting on real-world experiences, expertise, authority, and the stone-cold trustworthiness that dictates their deployment and maintenance.

Authoritative industry standards further highlight the crucial aspect of reliability. With mining operations costing millions, if not billions, every second of downtime translates into hefty financial losses. Reliable conveyor rollers mitigate these risks, ensuring continuous operations. Trusted manufacturers often provide detailed analytics and predictive maintenance schedules, allowing operators to proactively monitor and address potential issues before they culminate in operational stoppages. Such tools are indispensable, offering operators a rare blend of transparency and control over their mining activities. The user experience with conveyor rollers stems from both the ease of installation and the routine maintenance schedules they demand. Modern advancements have enabled the development of lighter and more robust rollers that provide ease of installation without compromising on strength. Maintenance practices have evolved, too, with modular designs and accessible components allowing technicians to swiftly address and resolve mechanical issues without significant disruptions to production. In essence, mining conveyor rollers are the critical arteries of the mining industry, enabling efficiency and reliability on a scale that defines the viability of contemporary mining endeavors. Their continued innovation and adaptation underscore the expertise that drives the industry forward, always on the cusp of technological advancement. Mining operations that prioritize the integration of high-quality conveyor rollers are better positioned to sustain their competitive edge, ensuring their productivity remains unchallenged while also mitigating operational risks. As the mining landscape evolves, so too will the advancement strategies surrounding these crucial components, reflecting a steadfast commitment to excellence and trust in industrial operations.

Authoritative industry standards further highlight the crucial aspect of reliability. With mining operations costing millions, if not billions, every second of downtime translates into hefty financial losses. Reliable conveyor rollers mitigate these risks, ensuring continuous operations. Trusted manufacturers often provide detailed analytics and predictive maintenance schedules, allowing operators to proactively monitor and address potential issues before they culminate in operational stoppages. Such tools are indispensable, offering operators a rare blend of transparency and control over their mining activities. The user experience with conveyor rollers stems from both the ease of installation and the routine maintenance schedules they demand. Modern advancements have enabled the development of lighter and more robust rollers that provide ease of installation without compromising on strength. Maintenance practices have evolved, too, with modular designs and accessible components allowing technicians to swiftly address and resolve mechanical issues without significant disruptions to production. In essence, mining conveyor rollers are the critical arteries of the mining industry, enabling efficiency and reliability on a scale that defines the viability of contemporary mining endeavors. Their continued innovation and adaptation underscore the expertise that drives the industry forward, always on the cusp of technological advancement. Mining operations that prioritize the integration of high-quality conveyor rollers are better positioned to sustain their competitive edge, ensuring their productivity remains unchallenged while also mitigating operational risks. As the mining landscape evolves, so too will the advancement strategies surrounding these crucial components, reflecting a steadfast commitment to excellence and trust in industrial operations.

Next:

Latest news

-

The Unrivaled Performance of Polyurethane Pulleys in Industrial ApplicationsNewsAug.25,2025

-

The Critical Role of Drum Lagging in Conveyor SystemsNewsAug.25,2025

-

Navigating Industrial Efficiency: The Critical Role of Conveyor PulleysNewsAug.25,2025

-

InIntroduction to Advanced Pulley Lagging SolutionsNewsAug.25,2025

-

Industry Trends in Pulley Lagging TechnologyNewsAug.25,2025

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

OUR PRODUCTS