Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu មករា . 14, 2025 09:48

Back to list

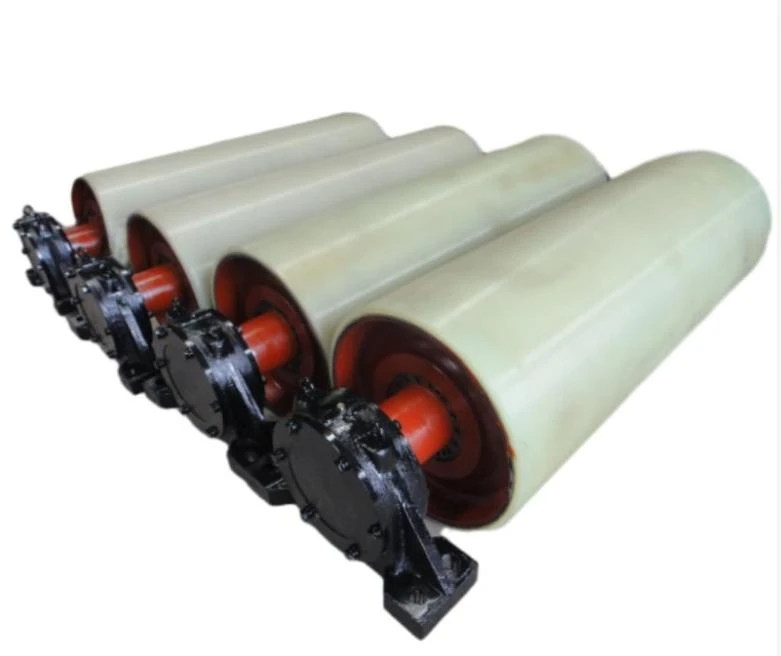

self cleaning return idlers

Self-cleaning return idlers are an innovative solution in the realm of bulk material handling, particularly advantageous for industries that manage substantial quantities of materials such as mining, quarrying, and agriculture. These components play a crucial role in maintaining the efficiency and longevity of conveyor systems. Constructed with the purpose of preventing material build-up on the return side of conveyor belts, they ensure that the machinery operates smoothly without unnecessary stoppages for maintenance, ultimately saving both time and resources.

Drawing from authoritative insights, many industry reports and case studies highlight the substantial cost savings associated with self-cleaning return idlers. Reducing the frequency of conveyor stoppages not only increases productivity but also extends the life of the conveyor belt and other components, leading to lower overall maintenance and replacement costs. Independent studies have demonstrated that companies investing in such equipment experience a return on investment (ROI) within a remarkably short period, confirming the financial prudence of these installations. Trust in self-cleaning return idlers is further validated by their broad adoption across various sectors. Leading global mining corporations and material handling experts advocate for their use, sharing anecdotal successes that underscore reliability and performance improvements. The consistent positive feedback and endorsements from industry veterans underscore the trustworthiness of self-cleaning return idlers as a solution for common conveyor belt issues. In conclusion, self-cleaning return idlers represent a targeted solution to enhance conveyor system efficiency, reduce operational downtime, and lower maintenance costs. Their innovative design, coupled with proven performance and strong endorsements from industry leaders, makes them an invaluable addition to any material handling process. As material handling needs continue to evolve, staying informed of advancements in technology and best practices, like those offered by self-cleaning return idlers, can lead to significant operational advantage and long-term success.

Drawing from authoritative insights, many industry reports and case studies highlight the substantial cost savings associated with self-cleaning return idlers. Reducing the frequency of conveyor stoppages not only increases productivity but also extends the life of the conveyor belt and other components, leading to lower overall maintenance and replacement costs. Independent studies have demonstrated that companies investing in such equipment experience a return on investment (ROI) within a remarkably short period, confirming the financial prudence of these installations. Trust in self-cleaning return idlers is further validated by their broad adoption across various sectors. Leading global mining corporations and material handling experts advocate for their use, sharing anecdotal successes that underscore reliability and performance improvements. The consistent positive feedback and endorsements from industry veterans underscore the trustworthiness of self-cleaning return idlers as a solution for common conveyor belt issues. In conclusion, self-cleaning return idlers represent a targeted solution to enhance conveyor system efficiency, reduce operational downtime, and lower maintenance costs. Their innovative design, coupled with proven performance and strong endorsements from industry leaders, makes them an invaluable addition to any material handling process. As material handling needs continue to evolve, staying informed of advancements in technology and best practices, like those offered by self-cleaning return idlers, can lead to significant operational advantage and long-term success.

Latest news

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025

OUR PRODUCTS