Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu កុម្ភៈ . 19, 2025 01:36

Back to list

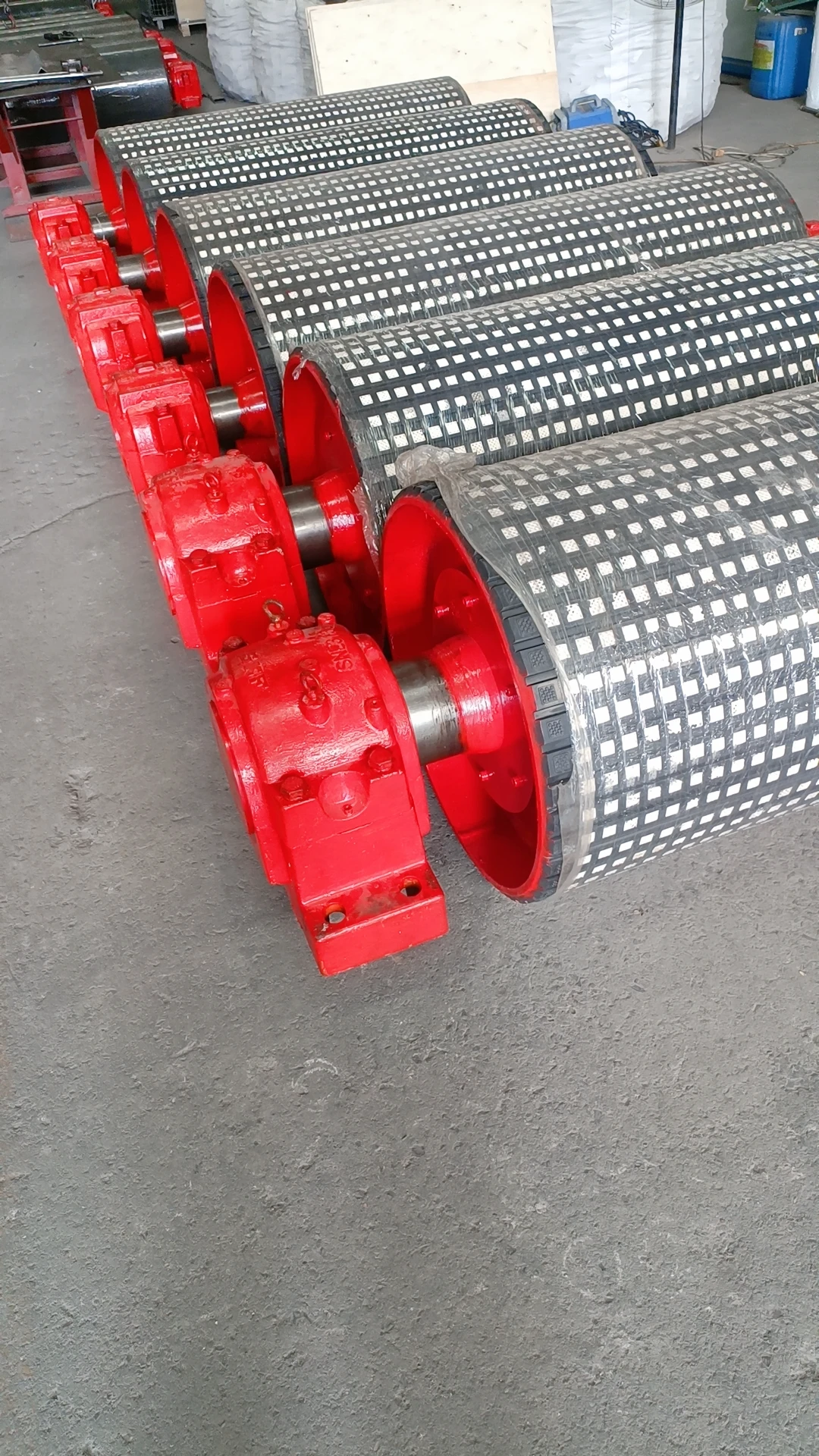

non-drive pulley

In the realm of mechanical engineering and industrial machinery, the non-drive pulley often remains overshadowed by its more dynamic companion, the drive pulley. However, what many don't realize is the pivotal role that the non-drive pulley plays in maintaining the integrity and effectiveness of any pulley system. As a seasoned SEO specialist with a deep understanding of industrial products, let me guide you through the remarkable world of non-drive pulleys and why they deserve a spotlight.

Industry experts recommend regular maintenance and timely replacement of non-drive pulleys to ensure optimal system functionality. Inspecting for signs of wear such as fraying belts, squealing noises, or visible damages can significantly reduce downtime and prevent costly repairs. In commercial and industrial applications, these practices underscore the necessity of reliable non-drive pulleys for uninterruptible operations. Furthermore, advancements in manufacturing technology have introduced non-drive pulleys with enhanced features, such as self-lubricating bearings and corrosion-resistant coatings. These improvements validate the ever-evolving nature of mechanical components and underscore the adaptability of non-drive pulleys in meeting modern engineering challenges. For businesses, investing in high-quality, reliable non-drive pulleys translates into sustained operational efficiency and reduced maintenance costs. Trust in industry-proven brands and specifications that meet stringent quality standards enables continued productivity and safety. In conclusion, while non-drive pulleys may not hold the spotlight in mechanical systems as their drive counterparts do, their role in ensuring smooth, effective operations is undeniable. For those in the market to optimize their machinery's performance, focusing on the right non-drive pulley choices can yield substantial benefits. Embracing their value not only confirms expert understanding but also elevates operational trust and authority in any mechanical endeavor.

Industry experts recommend regular maintenance and timely replacement of non-drive pulleys to ensure optimal system functionality. Inspecting for signs of wear such as fraying belts, squealing noises, or visible damages can significantly reduce downtime and prevent costly repairs. In commercial and industrial applications, these practices underscore the necessity of reliable non-drive pulleys for uninterruptible operations. Furthermore, advancements in manufacturing technology have introduced non-drive pulleys with enhanced features, such as self-lubricating bearings and corrosion-resistant coatings. These improvements validate the ever-evolving nature of mechanical components and underscore the adaptability of non-drive pulleys in meeting modern engineering challenges. For businesses, investing in high-quality, reliable non-drive pulleys translates into sustained operational efficiency and reduced maintenance costs. Trust in industry-proven brands and specifications that meet stringent quality standards enables continued productivity and safety. In conclusion, while non-drive pulleys may not hold the spotlight in mechanical systems as their drive counterparts do, their role in ensuring smooth, effective operations is undeniable. For those in the market to optimize their machinery's performance, focusing on the right non-drive pulley choices can yield substantial benefits. Embracing their value not only confirms expert understanding but also elevates operational trust and authority in any mechanical endeavor.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS