Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu កុម្ភៈ . 20, 2025 05:36

Back to list

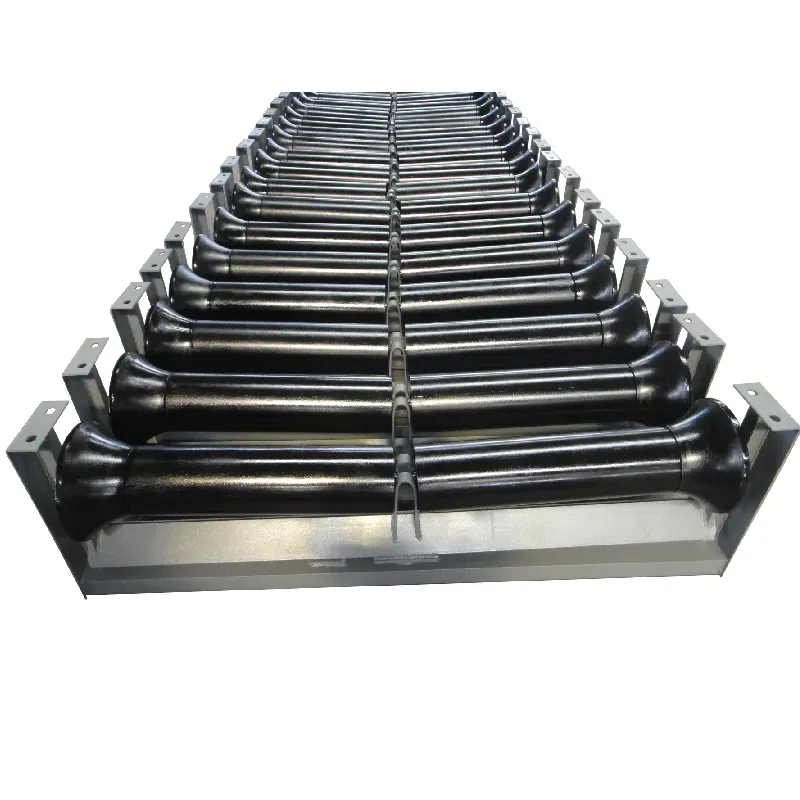

conveyor bend pulley

Conveyor bend pulleys, integral components of any conveyor belt system, ensure smooth directional changes and maintain optimal tension across the conveyor line. These essential parts are paramount in industries from mining to manufacturing, where efficient material handling equates to significant time and cost savings. Understanding the multifaceted functions and benefits of conveyor bend pulleys can enhance operational efficiency, reduce downtime, and extend the life of conveyor systems.

Moreover, the integration of vibration-damping features in some pulley designs helps minimize noise and material degradation. This can reduce the need for supplementary noise-reducing measures within the plant, leading to a quieter, more pleasant work environment. By diminishing the harmful effects of vibration, these advanced features enhance both worker satisfaction and longevity of the conveyor system. Successful implementation of conveyor bend pulleys also involves a comprehensive understanding of the material characteristics they are designed to handle. Factors such as the material type, particle size, and throughput requirements determine the precise specifications needed for optimal system performance. Customizing pulleys to match these specifications maximizes efficiency, reduces energy consumption, and minimizes wear on both the pulley and the belt. Lastly, the integration of smart technologies into conveyor bend pulleys is becoming increasingly prevalent. By equipping pulleys with sensors and IoT capabilities, operators can monitor real-time data on pulley performance and environmental conditions. This data-driven approach allows for proactive maintenance, reducing unexpected failures and extending the lifespan of the conveyor framework. Predictive analytics can preemptively identify potential issues, allowing for targeted interventions that keep systems running smoothly. In sum, conveyor bend pulleys are vital to the functionality and efficiency of modern conveyor systems. Their design, material composition, and placement directly influence system performance, maintenance schedules, and overall operational costs. By leveraging advanced technologies and ensuring proper maintenance, plant operators can realize significant gains in productivity, efficiency, and cost-effectiveness through the optimal use of conveyor bend pulleys. Prioritizing the quality and suitability of bend pulleys aligns with the broader industry goals of reducing waste, enhancing safety, and optimizing resource use.

Moreover, the integration of vibration-damping features in some pulley designs helps minimize noise and material degradation. This can reduce the need for supplementary noise-reducing measures within the plant, leading to a quieter, more pleasant work environment. By diminishing the harmful effects of vibration, these advanced features enhance both worker satisfaction and longevity of the conveyor system. Successful implementation of conveyor bend pulleys also involves a comprehensive understanding of the material characteristics they are designed to handle. Factors such as the material type, particle size, and throughput requirements determine the precise specifications needed for optimal system performance. Customizing pulleys to match these specifications maximizes efficiency, reduces energy consumption, and minimizes wear on both the pulley and the belt. Lastly, the integration of smart technologies into conveyor bend pulleys is becoming increasingly prevalent. By equipping pulleys with sensors and IoT capabilities, operators can monitor real-time data on pulley performance and environmental conditions. This data-driven approach allows for proactive maintenance, reducing unexpected failures and extending the lifespan of the conveyor framework. Predictive analytics can preemptively identify potential issues, allowing for targeted interventions that keep systems running smoothly. In sum, conveyor bend pulleys are vital to the functionality and efficiency of modern conveyor systems. Their design, material composition, and placement directly influence system performance, maintenance schedules, and overall operational costs. By leveraging advanced technologies and ensuring proper maintenance, plant operators can realize significant gains in productivity, efficiency, and cost-effectiveness through the optimal use of conveyor bend pulleys. Prioritizing the quality and suitability of bend pulleys aligns with the broader industry goals of reducing waste, enhancing safety, and optimizing resource use.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS