Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu កុម្ភៈ . 20, 2025 06:38

Back to list

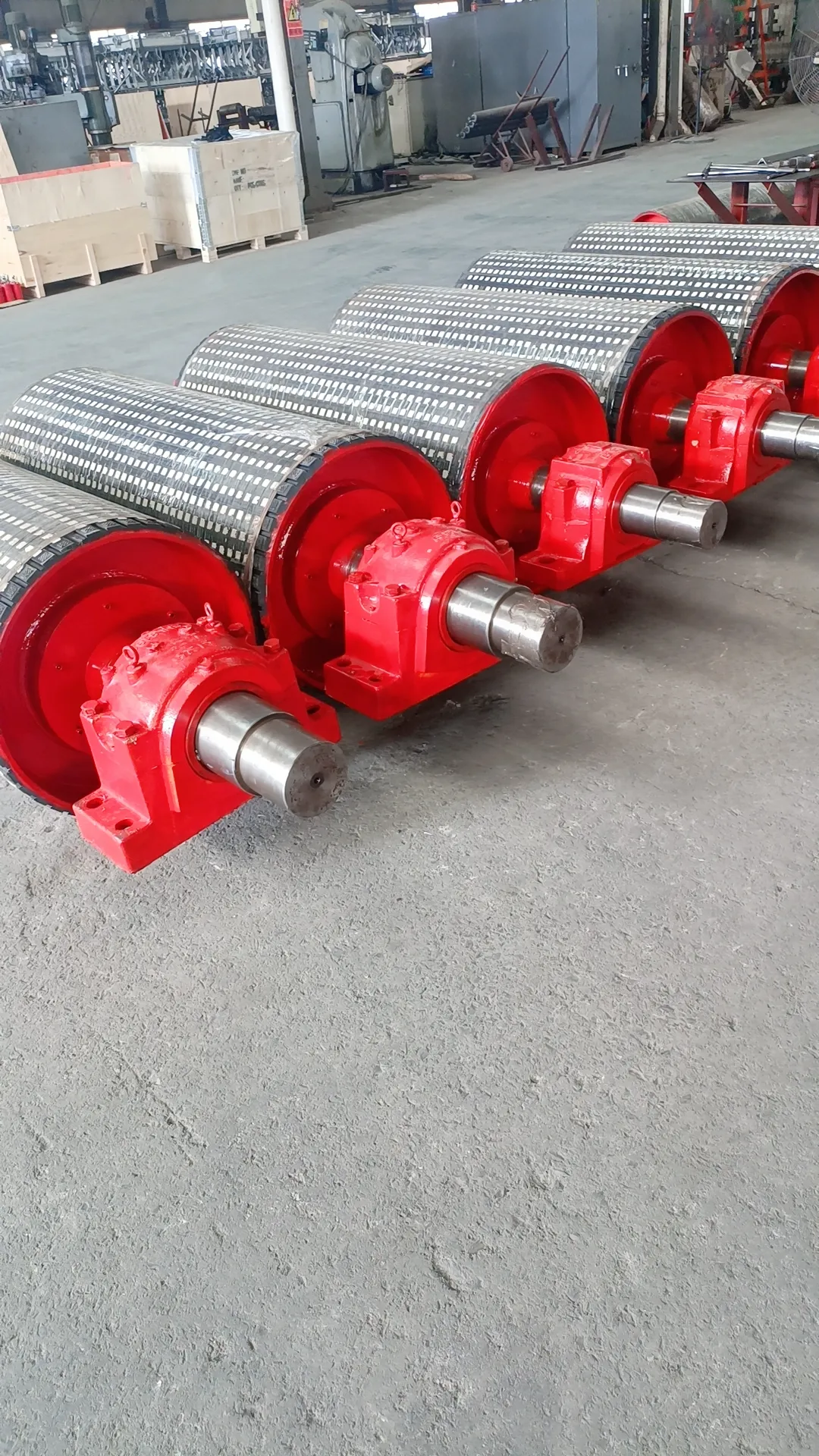

belt conveyor pulley

In the world of industrial machinery, conveyor belt drive pulleys play an irreplaceable role in various sectors, from mining to manufacturing. These pulleys are not just mechanical components; they are pivotal players in ensuring the efficient and safe operation of conveyor systems. With years of hands-on experience and specialized knowledge, understanding the features, applications, and advancements in the design of conveyor belt drive pulleys is crucial for anyone seeking to optimize their operational processes.

Technology advancements have led to the introduction of high-performance drive pulleys that incorporate features such as self-cleaning, wear-resistant coatings, and dynamic balancing. These innovations reduce maintenance needs and extend the lifespan of both the pulley and the conveyor belt, aiding in cost reduction and increased uptime. When evaluating the trustworthiness and reliability of a conveyor belt drive pulley, it’s essential to consider brand reputation and compliance with industry standards such as ISO 9001. Trustworthy manufacturers are transparent about their testing procedures and quality control measures, ensuring that every pulley meets rigorous performance criteria. Moreover, expert insights highlight the importance of regular maintenance and inspection. Keeping the drive pulley in optimal condition involves monitoring for wear and tear, alignment issues, and surface condition. Routine checks can prevent potential failures that might lead to production downtimes and financial losses. To sum up, conveyor belt drive pulleys are indispensable components that significantly influence the functionality and efficiency of conveyor systems. Their selection and maintenance require a balance of technical expertise, industry insight, and trust in quality standards. By leveraging these factors, industries can optimize their operations, ensuring smoother processes and enhanced performance, ultimately contributing to operational success and longevity. In essence, embracing the progressive developments and guided choices in the realm of conveyor belt drive pulleys empowers industries to maintain a competitive edge, ensuring safety, efficiency, and sustainability in their operations.

Technology advancements have led to the introduction of high-performance drive pulleys that incorporate features such as self-cleaning, wear-resistant coatings, and dynamic balancing. These innovations reduce maintenance needs and extend the lifespan of both the pulley and the conveyor belt, aiding in cost reduction and increased uptime. When evaluating the trustworthiness and reliability of a conveyor belt drive pulley, it’s essential to consider brand reputation and compliance with industry standards such as ISO 9001. Trustworthy manufacturers are transparent about their testing procedures and quality control measures, ensuring that every pulley meets rigorous performance criteria. Moreover, expert insights highlight the importance of regular maintenance and inspection. Keeping the drive pulley in optimal condition involves monitoring for wear and tear, alignment issues, and surface condition. Routine checks can prevent potential failures that might lead to production downtimes and financial losses. To sum up, conveyor belt drive pulleys are indispensable components that significantly influence the functionality and efficiency of conveyor systems. Their selection and maintenance require a balance of technical expertise, industry insight, and trust in quality standards. By leveraging these factors, industries can optimize their operations, ensuring smoother processes and enhanced performance, ultimately contributing to operational success and longevity. In essence, embracing the progressive developments and guided choices in the realm of conveyor belt drive pulleys empowers industries to maintain a competitive edge, ensuring safety, efficiency, and sustainability in their operations.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS