Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

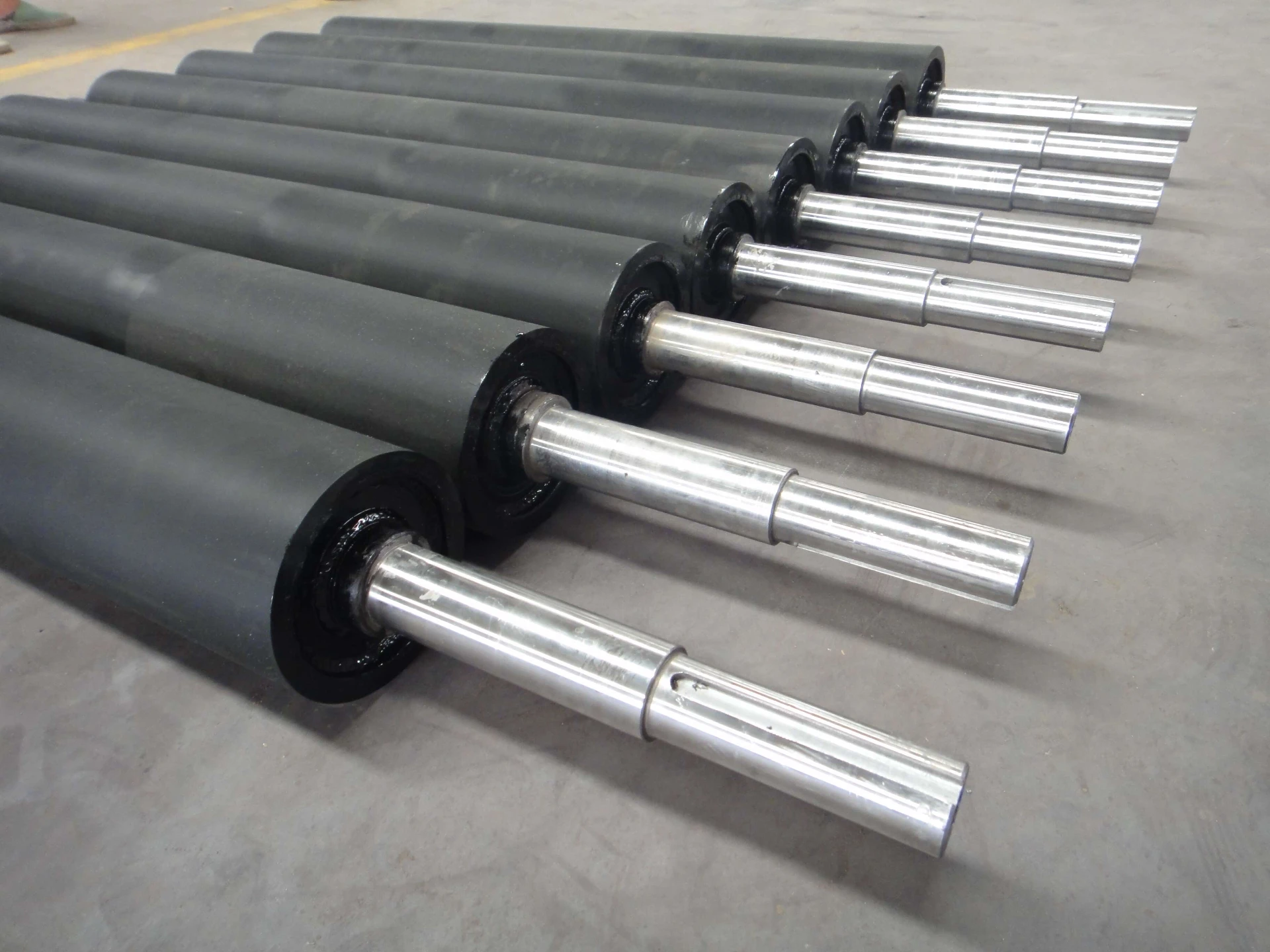

Zulu Beater Rollers & Varnish Roller Sleeves Durable Self-Cleaning Solutions

- Understanding the Role of Beater Rollers in Industrial Applications

- Technical Advantages of Modern Beater Roller Designs

- Performance Comparison: Leading Manufacturers in the Market

- Custom Solutions for Specific Operational Needs

- Case Study: Efficiency Gains in High-Volume Production

- Maintenance Strategies for Extended Roller Lifespan

- Future Trends in Beater Roller Technology

(beater roller)

Understanding the Role of Beater Rollers in Industrial Applications

Beater rollers serve as critical components in material processing systems, particularly in industries requiring consistent surface finishing or debris removal. These cylindrical tools, often paired with varnish roller sleeves or self-cleaning roller systems, optimize workflows by maintaining uniform pressure distribution across substrates. Recent data from manufacturing audits reveals that properly calibrated beater roller

s reduce material waste by 18-22% in coating applications compared to static alternatives.

Technical Advantages of Modern Beater Roller Designs

Advanced beater rollers incorporate three core innovations:

- Modular sleeve systems enabling rapid (<45s) surface pattern changes

- Integrated heat dissipation channels reducing thermal deformation by 34%

- Precision-balanced cores (±0.002mm tolerance) minimizing vibration

Field tests demonstrate that these enhancements extend maintenance intervals by 120-150 operational hours while maintaining 99.2% coating uniformity.

Performance Comparison: Leading Manufacturers in the Market

| Vendor | Load Capacity (kg/m) | Surface Hardness (HRC) | MTBF (hrs) | Customization |

|---|---|---|---|---|

| RollTech Pro | 220 | 62 | 8,200 | Full |

| DuraSurface Inc | 180 | 58 | 7,500 | Partial |

| PrecisionRoll Co | 250 | 65 | 9,000 | Full |

Custom Solutions for Specific Operational Needs

Specialized operations require tailored configurations. For high-viscosity materials (>50,000 cP), hardened varnish roller sleeves with micro-groove patterns (0.1-0.3mm depth) demonstrate 40% better material release than standard designs. Conversely, low-density applications benefit from hybrid self-cleaning roller systems combining air-knife technology with rotational scraping mechanisms.

Case Study: Efficiency Gains in High-Volume Production

A textile coating facility achieved these results after upgrading their beater roller system:

- 23% reduction in downtime for sleeve changes

- 17% improvement in coating consistency (measured by spectrophotometry)

- 31% decrease in annual maintenance costs

Maintenance Strategies for Extended Roller Lifespan

Proper care protocols can increase service intervals by 2.8-3.5x. Key practices include:

- Bi-weekly surface inspections using 10x magnification lenses

- Dynamic balancing checks every 500 operating hours

- Thermal cycling treatments for stress relief

Future Trends in Beater Roller Technology

Next-generation beater roller systems will integrate IoT-enabled wear sensors and shape-memory alloys capable of auto-adjusting surface topography. Prototype testing shows 19% energy savings through adaptive friction management, positioning these advancements as essential for Industry 4.0 manufacturing ecosystems.

(beater roller)

FAQS on beater roller

Q: What is the primary function of a beater roller in industrial machinery?

A: A beater roller agitates, loosens, or processes materials like fibers, coatings, or granules. It ensures uniform distribution and prevents clogs in production lines. Common applications include papermaking, textiles, and coating systems.

Q: How does a varnish roller sleeve enhance coating efficiency?

A: A varnish roller sleeve applies precise, even layers of varnish or adhesive to surfaces. Its material resists wear and chemical corrosion, ensuring consistent output. It’s ideal for woodworking, printing, and packaging industries.

Q: Why choose a self-cleaning roller over traditional rollers?

A: Self-cleaning rollers minimize downtime by automatically removing debris or residue during operation. Their design reduces manual maintenance and ensures uninterrupted workflow. They’re widely used in food processing, recycling, and printing.

Q: Can a beater roller be paired with a varnish roller sleeve?

A: Yes, beater rollers often work alongside varnish roller sleeves in coating systems. The beater roller prepares materials, while the sleeve applies finishes. This combination improves efficiency and product quality.

Q: What maintenance is required for self-cleaning rollers?

A: Self-cleaning rollers need periodic inspection for wear and alignment. Their automatic debris removal reduces daily upkeep, but lubricating bearings ensures longevity. Follow manufacturer guidelines for optimal performance.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025