Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu 2月 . 13, 2025 03:26

Back to list

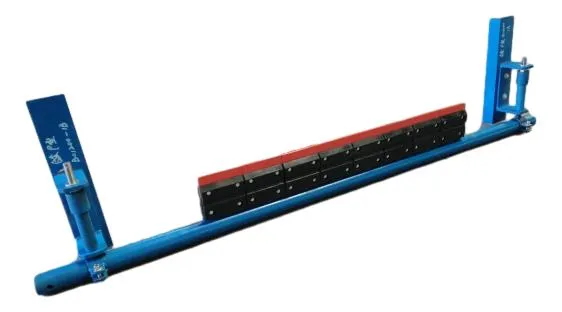

Customized Roller

The world of conveyor belt rollers is a fascinating realm where engineering precision meets material handling efficiency. Conveyor rollers are critical components in a wide range of industries, ensuring the seamless flow of goods and materials. Understanding the different types of conveyor belt rollers and their specific applications can greatly enhance operational productivity and cost-efficiency. This guide delves into the distinct types of conveyor belt rollers, illuminating their unique features and optimal use cases, drawing on decades of professional expertise and industry best practices.

Incorporating these rollers effectively requires an understanding of the operating environment and the specific materials being moved. Tailoring the roller selection to align with these constraints can enhance the reliability and efficiency of the entire conveyor system. For instance, stainless steel rollers or plastic options can be employed in food processing to adhere to sanitary standards, offering corrosion resistance and meeting hygiene protocols. Technical advancements have also paved the way for innovative roller solutions. Smart rollers equipped with sensors and IoT connectivity now allow real-time monitoring of system performance, facilitating predictive maintenance strategies. Such technology reduces downtime, extending the operational lifecycle of conveyor systems. With early detection of component wear or failure, potential disruptions can be minimized, reinforcing system dependability. The implementation of varied conveyor belt rollers is a testimony to the dynamic evolution of material handling technologies. Expert design and strategic deployment of these components underscore an intricate balance between functionality, durability, and adaptation to specific industrial requirements. For businesses, choosing the right type of conveyor roller holds the key to optimizing operations, ensuring a seamless material flow, and ultimately bolstering productivity and competitiveness. In conclusion, the ever-evolving landscape of conveyor belt rollers demonstrates significant strides in efficiency and application-specific expertise. By harnessing the right roller types, industries can achieve operational excellence, fortified by a foundation of innovation and a commitment to quality. As industries progress, so too will the technology of conveyor belt rollers, heralding a new era of material handling sophistication.

Incorporating these rollers effectively requires an understanding of the operating environment and the specific materials being moved. Tailoring the roller selection to align with these constraints can enhance the reliability and efficiency of the entire conveyor system. For instance, stainless steel rollers or plastic options can be employed in food processing to adhere to sanitary standards, offering corrosion resistance and meeting hygiene protocols. Technical advancements have also paved the way for innovative roller solutions. Smart rollers equipped with sensors and IoT connectivity now allow real-time monitoring of system performance, facilitating predictive maintenance strategies. Such technology reduces downtime, extending the operational lifecycle of conveyor systems. With early detection of component wear or failure, potential disruptions can be minimized, reinforcing system dependability. The implementation of varied conveyor belt rollers is a testimony to the dynamic evolution of material handling technologies. Expert design and strategic deployment of these components underscore an intricate balance between functionality, durability, and adaptation to specific industrial requirements. For businesses, choosing the right type of conveyor roller holds the key to optimizing operations, ensuring a seamless material flow, and ultimately bolstering productivity and competitiveness. In conclusion, the ever-evolving landscape of conveyor belt rollers demonstrates significant strides in efficiency and application-specific expertise. By harnessing the right roller types, industries can achieve operational excellence, fortified by a foundation of innovation and a commitment to quality. As industries progress, so too will the technology of conveyor belt rollers, heralding a new era of material handling sophistication.

Next:

Latest news

-

Taper Centering Idler Set for Conveyor SystemsNewsJun.25,2025

-

Small Idler Rollers for Industrial ConveyorsNewsJun.25,2025

-

Guide Training Idler Set for Conveyor MaintenanceNewsJun.25,2025

-

Friction Offset Idler Set for Industrial UseNewsJun.25,2025

-

Double-Center-Roller Idler AlignmentNewsJun.25,2025

-

Channel Inset Impact Troughing Idler Set for Heavy LoadsNewsJun.25,2025

OUR PRODUCTS