Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu rollers and brackets

Rollers and Brackets The Unsung Heroes of Mechanical Design

In the intricate world of mechanical engineering, the unsung heroes often go unnoticed. Among these are rollers and brackets, fundamental components that play crucial roles in a wide array of applications, from heavy machinery to everyday household items. Understanding their functions, types, and benefits can shed light on their significance in modern engineering.

The Function of Rollers

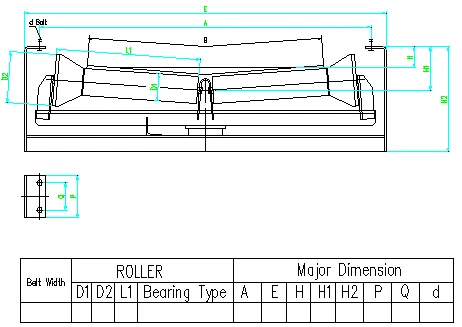

Rollers are cylindrical components that facilitate movement and reduce friction between surfaces. They are integral to various mechanisms, allowing for smooth transitions and easier navigation. For instance, in conveyor systems, rollers enable the continuous movement of goods, minimizing the amount of energy required to transport materials. Their design, typically consisting of a metallic or durable plastic outer casing, ensures longevity and efficiency.

There are several types of rollers, including guide rollers, tension rollers, and conveyor rollers, each tailored to specific purposes. Guide rollers, for instance, help maintain the alignment of moving parts, while tension rollers aid in controlling the tension of belts in machinery. By selecting the appropriate type of roller for a given application, engineers can enhance the overall performance and reliability of a machine.

The Role of Brackets

Brackets, on the other hand, serve as support structures, holding components in place and ensuring stability in various applications. They come in various shapes and sizes and are made from materials such as steel, aluminum, or plastic. Brackets are crucial in mounting everything from shelves and appliances to heavy machinery parts, providing the necessary support to withstand operational forces.

The design of brackets can vary significantly depending on their intended use. For example, L-brackets are commonly used for right-angle support, while angle brackets provide additional strength when joining two surfaces. By carefully selecting and positioning brackets, engineers can create a more robust and efficient assembly, reducing the likelihood of failures due to structural weaknesses.

rollers and brackets

Importance in Engineering

The importance of rollers and brackets in mechanical design cannot be overstated. They provide solutions that enhance efficiency, promote durability, and ensure the smooth operation of machines. In a world where precision and performance are paramount, these components contribute significantly to the reliability of complex systems.

Moreover, innovations in the design and manufacturing of rollers and brackets have led to improvements in their performance. For instance, advancements in materials science have led to the creation of lighter yet stronger composites, allowing for weight savings without sacrificing strength. Similarly, precision engineering techniques enable tighter tolerances in roller production, resulting in reduced friction and longer service life.

Applications Across Industries

Rollers and brackets find applications in a myriad of industries. In the automotive sector, they are essential in the assembly of vehicles, ensuring everything from the engine to the body components are securely held in place and operate smoothly. In the construction industry, brackets support various structures, ensuring they withstand both static and dynamic loads.

In the consumer goods sector, small-scale applications, such as furniture assembly and household fixtures, rely heavily on brackets for stability. Meanwhile, roller systems are ubiquitous in packaging and distribution centers, facilitating efficient workflows.

Conclusion

As we delve deeper into the world of mechanical design, the significance of rollers and brackets becomes increasingly apparent. These components, often overlooked, are essential for the smooth operation and structural integrity of countless systems, ranging from industrial machines to home appliances. Their contributions not only enhance efficiency and durability but also pave the way for advancements in technology and design. Recognizing the importance of these unsung heroes encourages us to appreciate the carefully engineered components that work tirelessly behind the scenes, making modern life possible. As we continue to innovate and design, rollers and brackets will remain fundamental to success, serving as the backbone of mechanical systems across all industries.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025