Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu 1月 . 26, 2025 05:03

Back to list

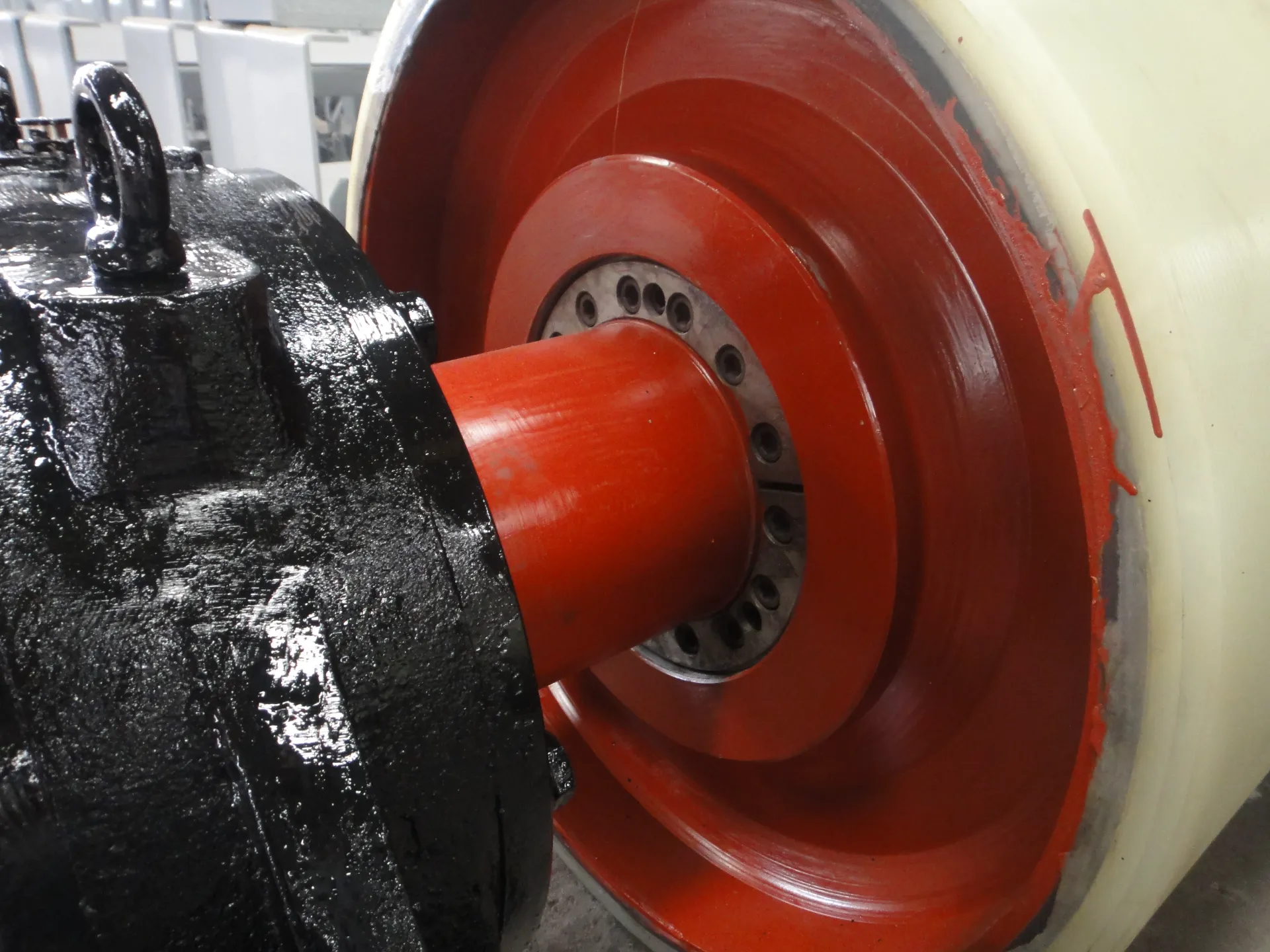

conveyor roller parts

In the ever-evolving landscape of industrial machinery, the significance of conveyor parts cannot be overstated. These essential components are the backbone of efficient material handling systems, playing a crucial role in diverse industries ranging from manufacturing to logistics.

Trust in conveyor parts also stems from their compliance with industry standards and testing for performance under real-world conditions. Leading manufacturers subject their components to rigorous quality control processes, emphasizing reliability and longevity. This process builds on decades of technological advancements and industry feedback, creating a trustworthy foundation for modern conveyor systems. Investments in high-quality conveyor parts have long-term benefits. They reduce downtime — a critical concern in industrial operations — by minimizing the need for frequent repairs and replacements. Furthermore, they enhance safety by preventing mishaps related to part failures. Such attention to safety regulations not only protects workers but also secures trust from stakeholders concerned about compliance and operational integrity. Emerging technologies continue to influence the production and design of conveyor parts. The incorporation of IoT sensors and smart technologies into conveyor systems offers advanced monitoring capabilities, allowing for real-time diagnostics and predictive maintenance. This evolution, respected by industry veterans, demonstrates the ongoing commitment to innovation and efficiency. Authoritative sources also emphasize the evolving nature of material handling needs, suggesting that businesses reassess their conveyor systems periodically. By evaluating current systems and investing in the latest conveyor parts, companies can maintain competitiveness and agility, adapting swiftly to market demands and technological advances. To ensure optimal selection and use of conveyor parts, seeking advice from seasoned professionals in industrial engineering is crucial. Their experience-based insights guide decision-making processes, ensuring that each component serves its intended purpose effectively while contributing to the broader objectives of operational efficiency and cost-effectiveness. In summary, the world of conveyor parts is vast and complex, where decisions influenced by experience, expertise, authority, and trustworthiness lead to enhanced operational outcomes. By focusing on these elements, industries set a strong foundation for success, driving forward with systems that are efficient, reliable, and future-ready.

Trust in conveyor parts also stems from their compliance with industry standards and testing for performance under real-world conditions. Leading manufacturers subject their components to rigorous quality control processes, emphasizing reliability and longevity. This process builds on decades of technological advancements and industry feedback, creating a trustworthy foundation for modern conveyor systems. Investments in high-quality conveyor parts have long-term benefits. They reduce downtime — a critical concern in industrial operations — by minimizing the need for frequent repairs and replacements. Furthermore, they enhance safety by preventing mishaps related to part failures. Such attention to safety regulations not only protects workers but also secures trust from stakeholders concerned about compliance and operational integrity. Emerging technologies continue to influence the production and design of conveyor parts. The incorporation of IoT sensors and smart technologies into conveyor systems offers advanced monitoring capabilities, allowing for real-time diagnostics and predictive maintenance. This evolution, respected by industry veterans, demonstrates the ongoing commitment to innovation and efficiency. Authoritative sources also emphasize the evolving nature of material handling needs, suggesting that businesses reassess their conveyor systems periodically. By evaluating current systems and investing in the latest conveyor parts, companies can maintain competitiveness and agility, adapting swiftly to market demands and technological advances. To ensure optimal selection and use of conveyor parts, seeking advice from seasoned professionals in industrial engineering is crucial. Their experience-based insights guide decision-making processes, ensuring that each component serves its intended purpose effectively while contributing to the broader objectives of operational efficiency and cost-effectiveness. In summary, the world of conveyor parts is vast and complex, where decisions influenced by experience, expertise, authority, and trustworthiness lead to enhanced operational outcomes. By focusing on these elements, industries set a strong foundation for success, driving forward with systems that are efficient, reliable, and future-ready.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS