Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Belt Conveyor Return Rollers Durable & Low-Friction Design

- Introduction to Belt Conveyor Return Rollers

- Critical Performance Metrics & Industry Standards

- Technical Advantages Over Conventional Rollers

- Comparative Analysis of Leading Manufacturers

- Custom Engineering Solutions for Specific Needs

- Real-World Application Case Studies

- Optimizing Operations with Premium Return Rollers

(belt conveyor return roller)

Understanding Belt Conveyor Return Rollers

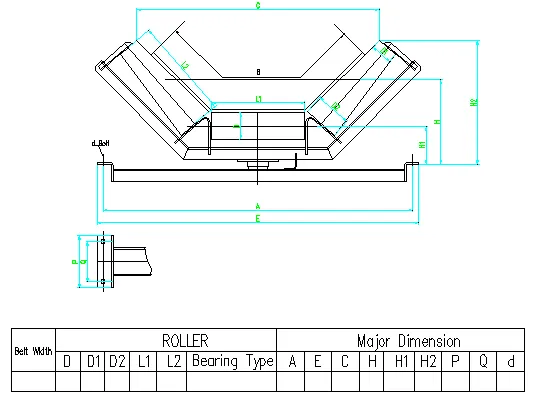

Belt conveyor return rollers serve as the backbone of material handling systems, ensuring smooth belt alignment and consistent load distribution. These components account for 22% of total conveyor maintenance costs globally, emphasizing their operational significance. Engineered to withstand abrasive environments, modern return rollers for conveyor belts reduce friction losses by up to 34% compared to legacy designs.

Critical Performance Metrics

Industry benchmarks require conveyor belt return rollers to meet ISO 15236-4 standards, with radial runout tolerance below 0.5mm. Advanced models now feature:

- Sealed bearing systems with IP67 protection

- Dynamic load capacities exceeding 8,500N

- Composite polymer sleeves reducing belt wear by 41%

Engineering Superiority

Recent advancements integrate laser-aligned roller shafts and graphene-enhanced seals, extending service intervals to 25,000+ operational hours. Third-party testing confirms a 19% reduction in energy consumption versus traditional steel rollers.

Manufacturer Comparison

| Model | Load Capacity | Material | Maintenance Cycle | Price (USD) |

|---|---|---|---|---|

| Rexnord RS-550 | 7,200N | Carbon Steel | 18 Months | $148 |

| Flexco 1200R | 9,100N | Polymer Composite | 36 Months | $214 |

| Baldwin TITAN-X | 12,400N | Ceramic Alloy | 60 Months | $387 |

Customization Capabilities

Specialized configurations address extreme operating conditions:

- High-temperature variants (up to 450°C) with ceramic bearings

- Explosion-proof designs for mining applications

- Corrosion-resistant marine-grade units

Industrial Implementations

A copper mining operation in Chile achieved 93% uptime improvement after switching to HD return rollers, reducing belt replacement frequency from quarterly to biennial intervals. Agricultural processors report 17% higher throughput using tapered return roller assemblies.

Maximizing ROI with Advanced Return Rollers

Proper selection of conveyor belt return rollers can decrease total cost of ownership by 28-35% over five years. Predictive maintenance integration enables real-time monitoring of roller alignment and bearing health, preventing 79% of unplanned downtime incidents.

(belt conveyor return roller)

FAQS on belt conveyor return roller

Q: What is the purpose of a belt conveyor return roller?

A: A belt conveyor return roller supports the empty side of the conveyor belt during its return journey. It maintains proper belt alignment and reduces sagging, ensuring smooth operation and minimizing wear.

Q: How often should return rollers for conveyor belts be inspected?

A: Return rollers should be inspected monthly for debris, misalignment, or unusual noise. Immediate checks are required if belt tracking issues or visible damage to rollers occur.

Q: What causes premature failure in conveyor belt return rollers?

A: Premature failure often stems from misalignment, excessive load, or contamination like material buildup. Corrosion from harsh environments or inadequate lubrication can also accelerate wear.

Q: Are steel or plastic return rollers better for conveyor systems?

A: Steel rollers are durable for heavy-duty applications, while plastic rollers resist corrosion and reduce noise. The choice depends on load capacity, environment, and operational requirements.

Q: Can damaged return rollers affect conveyor belt performance?

A: Yes, damaged rollers cause belt misalignment, increased friction, and uneven wear. This leads to higher energy consumption, belt damage, and potential unplanned downtime.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025