Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

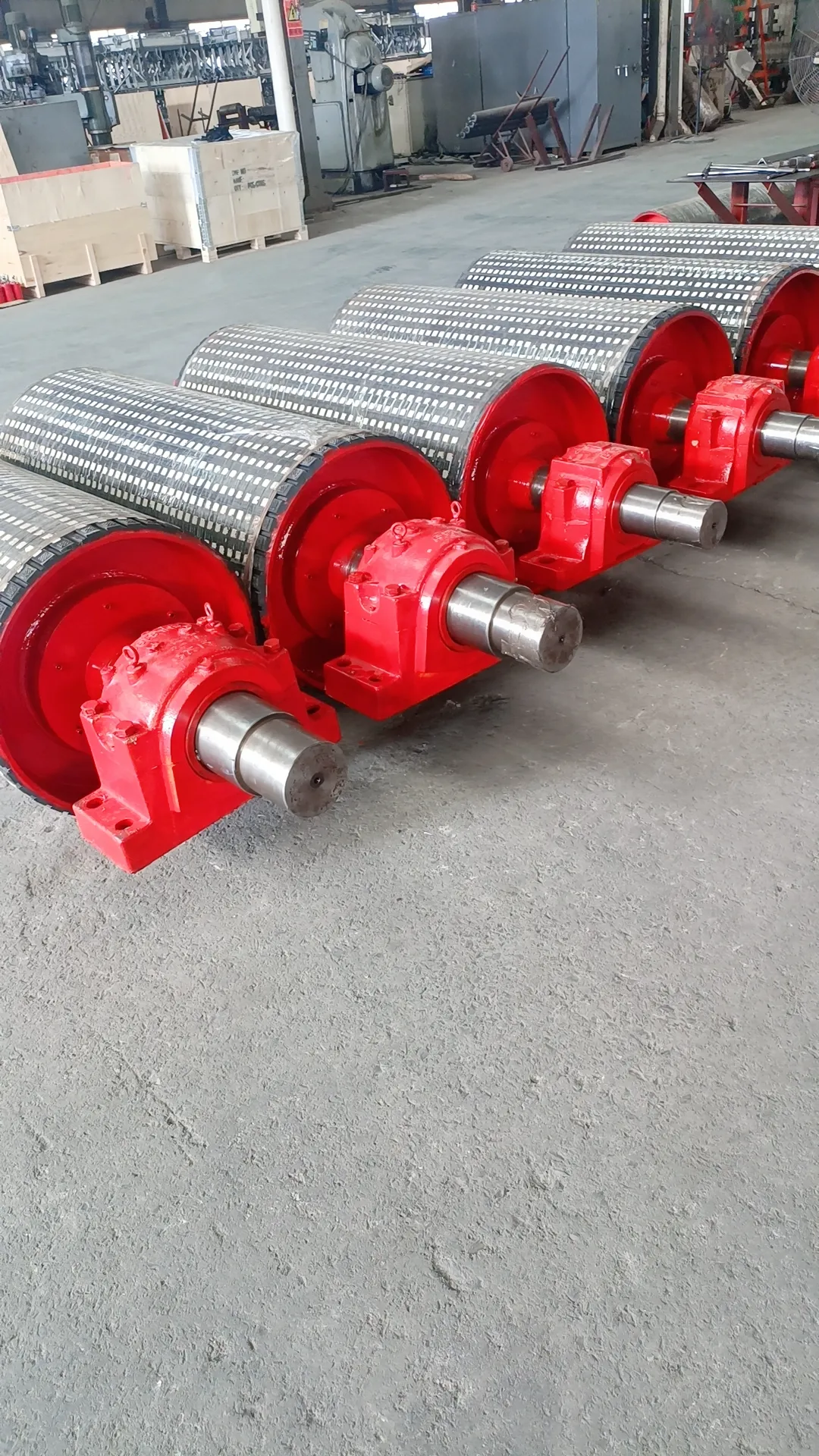

Zulu High-Quality Conveyor Rollers and Idlers for Efficient Material Handling Durable Rollers and Idlers Solutions

Transform Your Efficiency: Discover the Impact of Conveyor Rollers and Idlers

Imagine your production line comes to a halt. Downtime costs mount by the minute. According to a 2022 Deloitte study, unplanned stoppages slash manufacturing profits by 15% per year. What’s often the culprit behind these expensive delays? Worn-out, poorly designed conveyor rollers and idlers

. Your facility deserves better than bottlenecks and endless maintenance calls. Upgrading to premium rollers and idlers can reduce downtime by up to 60%. Ready to supercharge your workflow? Keep reading to elevate your business with cutting-edge conveyor solutions that make breakdowns a thing of the past.

(conveyor rollers and idlers)

The Technical Edge: Why Premium Conveyor Rollers and Idlers Matter

Not all rollers and idlers are created equal. Subpar components mean costly disruptions and safety hazards. Let’s break down what sets quality conveyor rollers and idlers apart.

- Heavy-duty construction minimizes deformation under load.

- Precision bearings reduce friction, saving energy.

- Anti-corrosive coatings withstand harsh environments and chemicals.

- Sealed designs block dust, dirt, and moisture for longer life.

Consider this: High-spec idlers and rollers can last up to five years longer than standard types. That means less replacement, fewer stoppages, and overall lower total cost of ownership.

Still using outdated equipment? There’s a clear technical (and financial) advantage to moving up.

Manufacturer Comparison: Standout Producers of Idlers and Rollers

Who you buy from matters! Supplier quality determines product lifespan, safety, and value. Let’s compare leaders in the market for conveyor rollers and idlers.

Pro tip: Always choose manufacturers who offer comprehensive warranties and certified materials. The upfront cost pays off in equipment reliability and peace of mind.

Customized Conveyor Rollers and Idlers: Tailored to Your Needs

Every operation is unique. Generic parts just don’t deliver optimal results. Why settle for off-the-shelf when you can have rollers and idlers designed for your specific materials, speeds, and loads?

- Variety of diameters and lengths

- Load-specific shell thickness

- Specialty coatings for corrosion or abrasion resistance

- Custom shaft designs—keyed, threaded, or grooved

- Adjustable noise and vibration dampening

Recently, an aggregate processing plant needed rollers with self-cleaning mechanisms. Our custom engineering slashed their cleaning downtimes by 40%. Imagine what tailored components could do for your facility. Ready to boost output and minimize headaches?

Real-World Application: Success Stories with Conveyor Rollers and Idlers

Let’s talk results. What do great rollers and idlers look like in action?

Case 1: Automotive Manufacturing

One Michigan plant switched to premium sealed idlers. Unexpected breakdowns dropped from monthly to annual events. Maintenance costs fell by 45%. Output soared, and deadlines were finally met.

Case 2: Steep-Incline Mining Conveyors

Custom composite rollers from our partners replaced traditional steel. Weight dropped by 35%, and operators reported far less belt drift. The low-vibration design reduced noise and extended belt life by 18% per internal audits.

Case 3: Parcel & Logistics Sorting

National postal hubs need high speed and zero downtime. Upgraded rollers and idlers increased throughput from 6,500 to 9,000 packages per hour. System failures are now virtually nonexistent.

Data-backed results prove one thing: Upgrading your idlers and rollers isn’t just a smart move. It’s the competitive edge your business deserves.

Specifications: Conveyor Rollers and Idlers at a Glance

Have a unique requirement? Contact our engineering team for a no-obligation solution that fits your exact specs.

Ready to Level Up? Let’s Get Rolling!

If conveyor rollers and idlers keep you up at night, you’re not alone. The wrong rollers stall profits, stress teams, and waste resources. But you don’t have to settle. Elevate your operations with rollers and idlers engineered for efficiency, durability, and the future.

Partner with DynoRoll Industries—the name trusted by facilities nationwide for conveyor rollers and idlers that outperform. From off-the-shelf to fully custom, every solution we provide is backed by solid guarantees and rapid lead-times. Ready to slash downtime, boost profits, and leave your competitors behind? Contact us today for your tailored quote. The perfect conveyor system is just a call or click away!

FAQs About Conveyor Rollers and Idlers

Q1: What are conveyor rollers and idlers, and why are they essential?

Conveyor rollers and idlers are core components in belt conveying systems. They support, guide, and drive the conveyor belt. Using high-quality rollers and idlers ensures belt alignment, reduces friction, and prevents system failures—maximizing uptime and productivity.

Q2: How do I choose the right rollers and idlers for my application?

Consider load weight, belt speed, environmental conditions, and application type. You can also ask for technical assistance from our team. We’ll recommend the best combination of size, material, and design for your needs.

Q3: Can conveyor rollers and idlers be customized?

Absolutely! We specialize in custom solutions. Options include diameter, material, coatings, shaft configuration, and even noise/vibration control features. Send your requirements—we make it easy!

Q4: What maintenance do idlers and rollers require?

Minimal maintenance is needed for sealed, high-quality rollers and idlers. Regular inspection for wear and cleaning helps. If you spot damage or resistance, replacements are quick and simple.

Q5: What is the average lifespan of quality conveyor rollers and idlers?

Premium products last 4 to 8 years, depending on the environment and load. Cheaper parts might fail in as little as 1-2 years, causing more downtime and higher costs overall.

Q6: Do better rollers and idlers really save money?

Yes! Our clients report up to 60% fewer breakdowns, 15-50% less energy use, and much lower total maintenance spend. Investing in quality pays off year after year.

Q7: What industries benefit most from upgraded idlers and rollers?

Industries include automotive, packaging, food processing, mining, logistics, and more. Any business needing reliable, continuous material handling can gain by switching to advanced conveyor rollers and idlers.

(conveyor rollers and idlers)

FAQS on conveyor rollers and idlers

Q: What are conveyor rollers and idlers?

A: Conveyor rollers and idlers are cylindrical components that support and guide conveyor belts. Rollers rotate to minimize friction, while idlers are assemblies that hold multiple rollers. Both are essential for smooth and efficient belt operation.Q: What is the main difference between rollers and idlers?

A: A roller is a single rotating cylinder, while an idler usually refers to a frame or assembly holding one or more rollers. Idlers are designed to provide belt support and maintain alignment. Both elements are crucial in conveyor systems.Q: How often should idlers and rollers be maintained?

A: Idlers and rollers should be inspected regularly, typically every few months, depending on usage. Proper maintenance helps avoid unexpected breakdowns and ensures belt longevity. Lubrication and cleaning are key maintenance tasks.Q: Can damaged conveyor rollers and idlers be repaired, or should they be replaced?

A: Minor issues with rollers and idlers can sometimes be repaired, such as tightening or lubricating. However, severely worn or damaged parts should be replaced to prevent conveyor failure. Using quality replacements ensures system reliability.Q: Are there different types of conveyor rollers and idlers for specific applications?

A: Yes, there are various types such as impact, return, and carrying rollers and idlers, each serving different purposes. Selection depends on belt type, material transported, and conveyor environment. Consulting a specialist helps choose the right type.-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025