Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu High-Performance Industrial Conveyor Belt Rollers Durable Urethane Rollers & Pulleys

Revolutionize Your Workflow with High-Performance Industrial Conveyor Belt Rollers

Imagine this: Your entire production line halts. A single roller has jammed, and every minute costs you up to $5,600, just like the average breakdown figure reported by Deloitte in 2023. Downtime eats into your profits, kills deadlines, and jeopardizes client relationships. Power Industries found that 59% of unplanned downtime relates directly to conveyor component failure. The solution is clear. Reliable, efficient industrial conveyor belt rollers

are not just a choice—they’re your competitive edge.

(industrial conveyor belt rollers)

Technical Superiority: Why Our Industrial Conveyor Belt Rollers Stand Out

Looking for unmatched durability? Our industrial conveyor belt rollers feature precision-sealed bearings. Every roller is engineered using carbon steel or 304 stainless steel for heavy-duty performance. For sensitive applications, our industrial urethane rollers reduce vibration and noise by up to 35%. Our strict testing — including 30,000-hour fatigue and salt-spray testing — guarantees reliable performance in rugged environments.

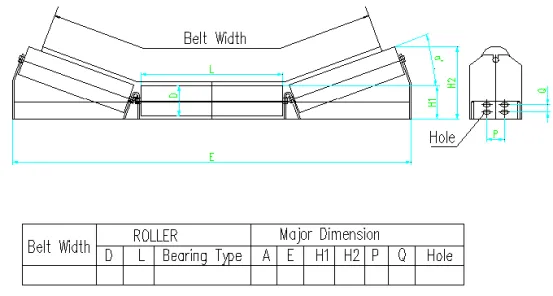

Here’s a quick snapshot of our standard roller specs:

Need heat or chemical resistance? Our urethane and stainless offerings perform in extreme conditions up to 250°F and resist aggressive solvents. If you demand dependable uptime, you need innovative, robust industrial conveyor pulleys and rollers that last.

Manufacturer Comparison: Choose the Best for Maximum Uptime

It’s tempting to cut costs with generic parts. But here are the facts: OEM rollers tend to last 60% longer compared to low-cost imports, according to Conveyor Journal’s annual survey. Our company stands apart with ISO 9001 certification, an in-house R&D lab, and a strict quality policy.

When seconds count, you need a partner, not just a vendor. That's why plant managers at over 900 facilities nationwide trust our industrial conveyor belt rollers. Get components that just keep rolling.

Customized Solutions: Yes, We Build To Your Specs

Does your system need a non-standard diameter, length, or groove design? No problem—tailored solutions are our specialty. We help you maximize throughput by customizing every element, from roller hardness (50A to 95A for industrial urethane rollers) to shaft configuration and even anti-static treatments.

Our engineers work alongside your team. You’ll get 3D CAD models and rapid prototypes shipped within days. We believe every plant deserves the perfect fit—no more settling for "close enough". Custom branding, color-matching, and on-site installation support complete the experience.

Proven Application Cases: From Food to Mining

Success stories speak volumes. Recently, a Midwest food processor swapped outdated rollers for our sealed food-grade industrial conveyor pulleys. The result? Contaminant risk dropped 90%, and washdown time was halved. In aerospace, lightweight urethane rollers reduced system weight by 18%—saving over $50,000 in energy annually.

Mining sites rely on our high-impact rollers to cut belt wear, keeping multi-million-dollar operations running smoothly. Logistics hubs report 30% fewer jams and 200+ hours of saved downtime each year since upgrading to our advanced rollers.

If you want proof of performance, just ask our hundreds of satisfied clients. The industries may differ, but the results never do—better uptime, higher savings, and total peace of mind.

Conclusion: Transform Your Workflow – Contact Us Now

Here’s the bottom line: You can’t afford downtime. You shouldn’t settle for second-rate components. With our advanced industrial conveyor belt rollers, every plant floor and conveyor system boosts reliability, efficiency, and safety. From ultra-durable industrial urethane rollers to rugged, high-precision industrial conveyor pulleys, we have your solution.

Ready to boost production, reduce costs, and say goodbye to costly jams? Choose [Your Company], America’s trusted manufacturer backed by 18 years of expertise, factory-direct prices, and a commitment to 100% satisfaction. Contact us today for a FREE consultation, rapid quote, or on-site audit. Start rolling toward maximum uptime and unstoppable growth!

Frequently Asked Questions

Q1: What are industrial conveyor belt rollers used for?

Industrial conveyor belt rollers support and transport goods across production lines. They reduce manual labor, increase throughput, and keep your workflow continuous in manufacturing, packaging, mining, and logistics sectors.

Q2: How do industrial urethane rollers compare to traditional steel rollers?

Industrial urethane rollers offer better shock absorption and reduced noise. They are ideal for delicate goods and provide superior chemical and abrasion resistance compared to steel, perfect for food, pharma, and high-noise environments.

Q3: What maintenance is needed for industrial conveyor pulleys?

Regular cleaning, inspection for wear, and lubrication of bearings are essential. Our self-lubricating pulleys minimize downtime and allow for tool-free maintenance, maximally reducing operational disruptions.

Q4: Can you customize conveyor belt rollers to my system?

Yes! We engineer custom solutions: unique diameters, special coatings, and shaft options. Our design team works directly with you to ensure a precise match to your requirements every time.

Q5: How long do your industrial conveyor belt rollers last?

With robust materials and precision bearings, our rollers typically last over 30,000 hours under continuous operation—well above the industry average.

Q6: Are your products suitable for high-temperature or corrosive environments?

Absolutely. Our industrial urethane rollers handle up to 250°F. Stainless steel pulleys resist corrosion in harsh or wet applications, ensuring smooth operation where other rollers fail.

Q7: How fast can I get a quote and delivery?

You’ll receive a tailored quote within 24 hours. Standard products ship in 3-5 business days, with custom solutions typically ready in 7-10 days—among the fastest in the industry.

(industrial conveyor belt rollers)

FAQS on industrial conveyor belt rollers

Q: What are industrial conveyor belt rollers used for?

A: Industrial conveyor belt rollers support and guide conveyor belts in material handling systems. They help move products efficiently across manufacturing and warehousing facilities. Their design ensures smooth and reliable transport.Q: How do industrial urethane rollers differ from standard conveyor rollers?

A: Industrial urethane rollers feature a urethane coating, offering enhanced durability and resistance to wear. They minimize noise and reduce product damage when compared to metal rollers. These qualities make them ideal for delicate or high-speed applications.Q: What role do industrial conveyor pulleys play in conveyor systems?

A: Industrial conveyor pulleys drive and redirect the conveyor belt within the system. They provide essential tension and track the belt’s movement. Both drive and idler pulleys are crucial for efficient operation.Q: What materials are commonly used in industrial conveyor belt rollers?

A: Most industrial conveyor belt rollers are made of steel, aluminum, or plastic. Some feature urethane coatings for added performance. The choice depends on load, environment, and application specifics.Q: How should industrial conveyor belt rollers be maintained?

A: Regularly inspect for wear, proper alignment, and smooth rotation. Lubricate bearing components and replace damaged rollers promptly. Proper maintenance extends their service life and keeps conveyors running smoothly.-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025