Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Exploring the Importance and Functionality of Idlers and Rollers in Industrial Applications

Idler and Roller Key Components in Mechanical Systems

In the realm of mechanical engineering, the terms idler and roller often surface when discussing the functionality and efficiency of various systems, particularly in conveyor belts, manufacturing equipment, and material handling applications. Both components play crucial roles, yet they serve distinct purposes that contribute to the overall effectiveness of machinery.

Idler Defined

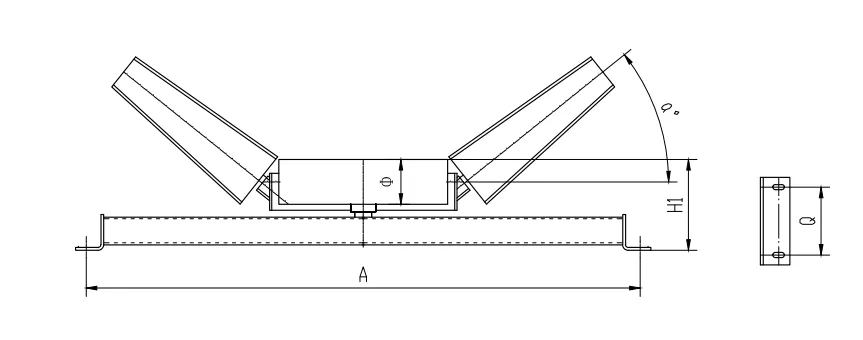

An idler is a kind of roller that is not powered but supports and guides the movement of a conveyor belt or a similar mechanism. Typically installed at certain intervals along the conveyor system, idlers help to keep the belt in alignment and reduce sagging between tension points. They may come in various forms—such as flat, trough, or rubber-topped—each suited for specific applications based on the material being transported and the overall design of the conveyor.

The primary function of an idler is to minimize friction and wear on the conveyor belt. By providing a smooth surface for the belt to glide over, idlers help in reducing the energy required to move materials, thereby improving operational efficiency. Additionally, proper idler selection and maintenance can significantly extend the lifespan of the conveyor system.

Roller Explained

In contrast, the term roller typically refers to a component that assists in the movement of loads by providing a rolling surface. Rollers can be powered or non-powered, depending on their application. For instance, powered rollers are often found in automated systems, such as roller conveyor systems, where they help to move items from one point to another through the application of motorized power.

idler and roller

Rollers can be configured in various arrangements—such as gravity rollers or powered rollers—to suit different operational needs. Gravity rollers rely on the force of gravity to transport goods downhill, while powered rollers use motors to drive products along a flat or inclined surface. This versatility makes rollers an integral part of material handling systems across industries, including warehousing, distribution centers, and manufacturing facilities.

Interrelationship of Idlers and Rollers

While idlers and rollers may serve different purposes, they often work together within a single system to achieve optimal performance. A conveyor system might utilize both components idlers to support and guide the belt while rollers help transport goods across varying distances. The combination of these elements ensures smooth operation, which is vital for the efficiency and productivity of industrial processes.

The synergy between idlers and rollers also highlights the importance of proper design and maintenance. Engineers must consider the specific needs of their application, such as load capacity, belt speed, and material characteristics, to select appropriate idlers and rollers. Regular inspections are crucial as well, as worn or damaged components can lead to increased downtime, costly repairs, and reduced operational efficiency.

Conclusion

In conclusion, idlers and rollers are essential components in mechanical systems that contribute to the efficiency and functionality of material handling processes. The choice between idler and roller depends on the specific needs of the system, but both work in tandem to ensure smooth operation and longevity. As technology advances, innovations in materials and design will likely enhance the performance of these components, leading to even greater efficiency in industrial applications. Understanding the roles of idlers and rollers, as well as their interrelationship, is critical for anyone involved in mechanical design and material handling operations.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025