Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  Englisch

Englisch  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Reliable Conveyor Pulley Upgrades

The ceramic lagging pulley has become one of the most effective upgrades in conveyor belt systems where grip and durability matter most. Unlike traditional rubber-lagged pulleys, ceramic lagging is built to resist slippage, even in wet, high-load, or abrasive environments. The ceramic tiles embedded on the pulley surface create a high-friction interface between the pulley and the belt, which enhances traction and reduces wear on both components. This is especially important in industries like mining, cement, or grain handling, where consistent belt movement directly affects productivity. The use of ceramic lagging pulleys also lowers the chances of belt misalignment and cuts down on overall maintenance, making it a practical and increasingly popular choice.

Conveyor Pulley Catalogue Simplifies Selection Process

Selecting the right pulley for your application can be overwhelming, which is why a well-organized conveyor pulley catalogue is so useful. Whether you're dealing with light-duty or heavy-duty applications, the catalogue breaks down the differences between drive pulleys, tail pulleys, and take-up pulleys, with clear technical specifications. From face widths and diameters to lagging types and shaft options, a comprehensive pulley catalogue allows buyers to compare products efficiently. Engineers and plant managers can use this tool to match pulleys with specific conveyor designs, reducing the risk of choosing incompatible parts. With so many pulley types available, the catalogue has become a trusted resource for both quick replacements and long-term system planning.

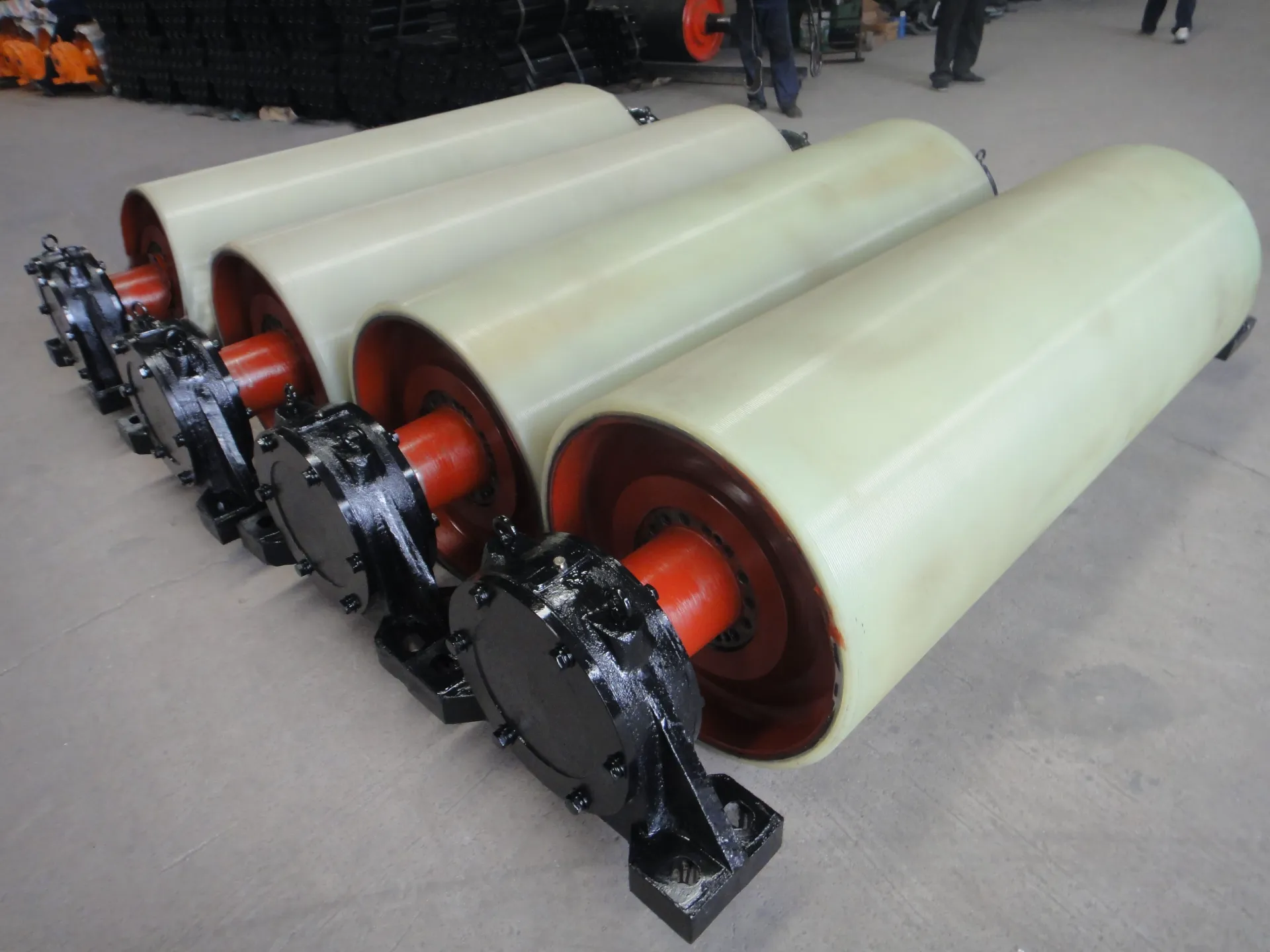

Drum Pulley for Conveyor Belt Improves Load Handling

Installing the right drum pulley for conveyor belt can significantly affect how well a system handles heavy loads and maintains tension. Drum pulleys are often used as head or tail pulleys, helping to drive the belt or redirect it at the end of the conveyor. Their solid construction allows them to support large material loads, and when fitted with appropriate lagging, they reduce belt slip and improve power transmission. A properly matched drum pulley enhances the belt's lifespan and minimizes costly downtime. They are commonly used in manufacturing, mining, and logistics sectors where precision in movement and torque matters. For operations seeking stability under constant use, the drum pulley remains a core piece of equipment.

Conveyor Pulley Bearing Assembly Ensures Smooth Motion

Behind every reliable pulley is a well-designed conveyor pulley bearing assembly, ensuring the smooth and steady rotation of the pulley. These assemblies are built to withstand radial and axial loads, especially in high-tension areas. The bearing housing must match the environmental needs—whether it's dust-proof, moisture-resistant, or designed for high-speed rotation. Quality bearing assemblies reduce energy consumption by limiting friction and help avoid sudden breakdowns that can halt production. Maintenance teams appreciate the modular design of many modern bearing units, which simplifies lubrication and inspection. For any conveyor system, upgrading to a high-performance bearing assembly pays off in fewer repairs and better uptime.

Types of Conveyor Belt Pulleys and Their Unique Uses

Understanding the types of conveyor belt pulleys helps businesses configure their systems for maximum output and efficiency. Drive pulleys provide the motion, take-up pulleys adjust the tension, snub pulleys increase wrap angle, and bend pulleys change direction. Each type serves a specific mechanical function that contributes to the system's balance and reliability. By selecting the right combination of pulley types, operators can prevent premature belt wear and system failure. This knowledge is particularly useful in industries with continuous operations, where even minor downtime can mean huge losses. Knowing the right pulley for each role is now easier than ever, thanks to improved catalogs and supplier support.

Ceramic Lagging Pulley FAQs

What is the main benefit of using a ceramic lagging pulley?

The main advantage is its superior grip and durability in harsh conditions, which reduces belt slippage and increases overall conveyor system efficiency.

Can I find all types of pulleys in a conveyor pulley catalogue?

Yes, a detailed conveyor pulley catalogue includes all types such as drive, tail, take-up, and snub pulleys, along with specifications to match system requirements.

When should I replace a drum pulley for a conveyor belt?

Replace the drum pulley when there are signs of excessive wear, shaft misalignment, or if the lagging starts to peel or crack under load pressure.

How often should a conveyor pulley bearing assembly be serviced?

Bearing assemblies should be checked regularly—at least once every three months—for signs of noise, vibration, or lubricant issues to ensure smooth operation.

Do different types of conveyor belt pulleys need different maintenance?

Yes, each type may require specific inspection and servicing intervals based on its function and the stress it handles in the conveyor setup.

When you're ready to reduce downtime, improve belt performance, and invest in durable materials, upgrading to a ceramic lagging pulley system with the right components is the smart move. Whether you're setting up a new conveyor or upgrading an old one, our full conveyor pulley catalogue makes choosing easy. Visit our site today to explore the range, speak to a product specialist, or get a quote. Start optimizing your system with long-lasting pulleys that deliver real results.

-

Revolutionizing Conveyor Systems with Spiral Return RollersNachrichtMay.27,2025

-

Reliable Conveyor Pulley UpgradesNachrichtMay.27,2025

-

Optimizing Conveyor Efficiency with Roll Table Convey RollersNachrichtMay.27,2025

-

Maximizing Conveyor Efficiency with Wing PulleysNachrichtMay.27,2025

-

Maximize Conveyor Efficiency with Impact BedsNachrichtMay.27,2025

-

Clean Belt SolutionsNachrichtMay.27,2025