Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jun . 25, 2024 02:45

Back to list

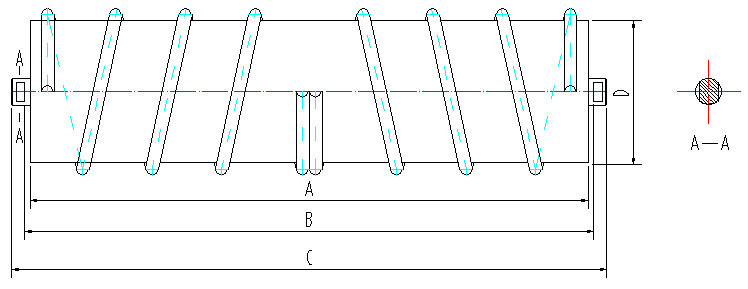

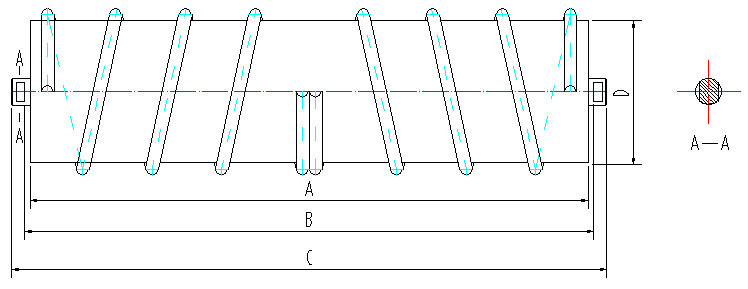

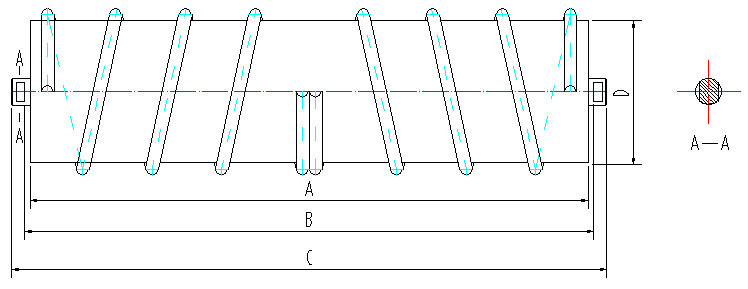

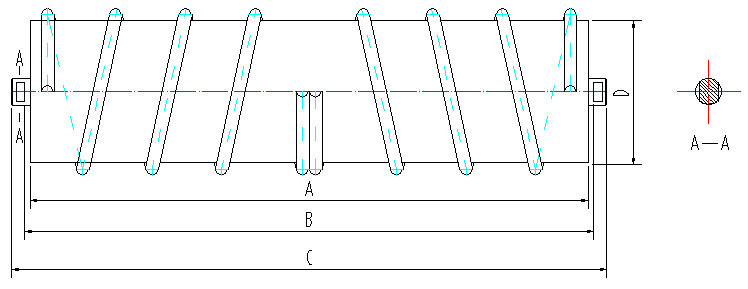

Design Principles Efficiency of Belt Conveyance with Bend and Snub Pulleys

The Ubiquitous Bend Pulley and Snub Pulley Efficiency in Mechanical Engineering

In the realm of mechanical engineering, two simple yet crucial components that play a pivotal role in the smooth functioning of various systems are the bend pulley and the snub pulley. These seemingly insignificant devices, often found in machinery from industrial factories to everyday household tools, exhibit remarkable engineering ingenuity and efficiency.

The bend pulley, also known as the V-belt pulley, is a versatile piece that bends to accommodate different belt profiles. Its design allows for easy installation and adjustment, making it ideal for power transmission in systems where space constraints are prevalent. The bend in its shape creates an efficient grip on the belt, minimizing slippage and maximizing torque transfer. It's particularly useful in applications where multiple drives or varying angles need to be accommodated, such as in conveyor belts or automotive engines.

On the other hand, the snub pulley, often referred to as a blocking pulley, serves a more protective function. It is strategically placed in the line of rotation to dampen vibrations and absorb shock loads, thereby preventing excessive wear and tear on the main drive system. The snub pulley acts as a safety measure, reducing the risk of sudden breaks or accidents by distributing the load more evenly. It is commonly seen in machinery like woodworking lathes or heavy-duty machinery, where abrupt stops can cause significant damage It is commonly seen in machinery like woodworking lathes or heavy-duty machinery, where abrupt stops can cause significant damage It is commonly seen in machinery like woodworking lathes or heavy-duty machinery, where abrupt stops can cause significant damage It is commonly seen in machinery like woodworking lathes or heavy-duty machinery, where abrupt stops can cause significant damage

It is commonly seen in machinery like woodworking lathes or heavy-duty machinery, where abrupt stops can cause significant damage It is commonly seen in machinery like woodworking lathes or heavy-duty machinery, where abrupt stops can cause significant damage bend pulley and snub pulley.

Both these pulleys, though distinct in their roles, share a common denominator – they enhance the overall performance and longevity of a machine. By improving the transmission of power, minimizing friction, and safeguarding against potential hazards, they contribute to the reliability and productivity of any mechanical setup.

Moreover, the design and choice of materials for these pulleys are critical factors in their effectiveness. Engineers must consider factors like load capacity, speed, and operating conditions to ensure optimal performance. Modern advancements in materials science have led to lightweight yet durable options, further boosting efficiency and energy savings.

In conclusion, the bend pulley and snub pulley are humble but indispensable elements in the world of mechanical engineering. Their combined presence ensures that complex systems operate smoothly, efficiently, and safely. As technology continues to evolve, so does the sophistication of these simple yet powerful components, making them an integral part of the modern industrial landscape.

bend pulley and snub pulley.

Both these pulleys, though distinct in their roles, share a common denominator – they enhance the overall performance and longevity of a machine. By improving the transmission of power, minimizing friction, and safeguarding against potential hazards, they contribute to the reliability and productivity of any mechanical setup.

Moreover, the design and choice of materials for these pulleys are critical factors in their effectiveness. Engineers must consider factors like load capacity, speed, and operating conditions to ensure optimal performance. Modern advancements in materials science have led to lightweight yet durable options, further boosting efficiency and energy savings.

In conclusion, the bend pulley and snub pulley are humble but indispensable elements in the world of mechanical engineering. Their combined presence ensures that complex systems operate smoothly, efficiently, and safely. As technology continues to evolve, so does the sophistication of these simple yet powerful components, making them an integral part of the modern industrial landscape.

It is commonly seen in machinery like woodworking lathes or heavy-duty machinery, where abrupt stops can cause significant damage It is commonly seen in machinery like woodworking lathes or heavy-duty machinery, where abrupt stops can cause significant damage

It is commonly seen in machinery like woodworking lathes or heavy-duty machinery, where abrupt stops can cause significant damage It is commonly seen in machinery like woodworking lathes or heavy-duty machinery, where abrupt stops can cause significant damage bend pulley and snub pulley.

Both these pulleys, though distinct in their roles, share a common denominator – they enhance the overall performance and longevity of a machine. By improving the transmission of power, minimizing friction, and safeguarding against potential hazards, they contribute to the reliability and productivity of any mechanical setup.

Moreover, the design and choice of materials for these pulleys are critical factors in their effectiveness. Engineers must consider factors like load capacity, speed, and operating conditions to ensure optimal performance. Modern advancements in materials science have led to lightweight yet durable options, further boosting efficiency and energy savings.

In conclusion, the bend pulley and snub pulley are humble but indispensable elements in the world of mechanical engineering. Their combined presence ensures that complex systems operate smoothly, efficiently, and safely. As technology continues to evolve, so does the sophistication of these simple yet powerful components, making them an integral part of the modern industrial landscape.

bend pulley and snub pulley.

Both these pulleys, though distinct in their roles, share a common denominator – they enhance the overall performance and longevity of a machine. By improving the transmission of power, minimizing friction, and safeguarding against potential hazards, they contribute to the reliability and productivity of any mechanical setup.

Moreover, the design and choice of materials for these pulleys are critical factors in their effectiveness. Engineers must consider factors like load capacity, speed, and operating conditions to ensure optimal performance. Modern advancements in materials science have led to lightweight yet durable options, further boosting efficiency and energy savings.

In conclusion, the bend pulley and snub pulley are humble but indispensable elements in the world of mechanical engineering. Their combined presence ensures that complex systems operate smoothly, efficiently, and safely. As technology continues to evolve, so does the sophistication of these simple yet powerful components, making them an integral part of the modern industrial landscape. Latest news

-

Wing Pulley Conveyor for Conveyor Belt MaintenanceNewsJun.16,2025

-

Self Cleaning Spiral Idler for Conveyor DesignNewsJun.16,2025

-

Pulley Lagging for Conveyor Belt AlignmentNewsJun.16,2025

-

Impact Idlers Used in Belt Conveyor for PerformanceNewsJun.16,2025

-

Ceramic Lagging Conveyor Pulley for Conveyor Belt SystemsNewsJun.16,2025

-

Belt Conveyor Idler for Heavy-Duty ApplicationsNewsJun.16,2025

OUR PRODUCTS