Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Conveyor Pulley Design Standards and Performance Specifications for Optimal Efficiency

Understanding Conveyor Pulley Specifications

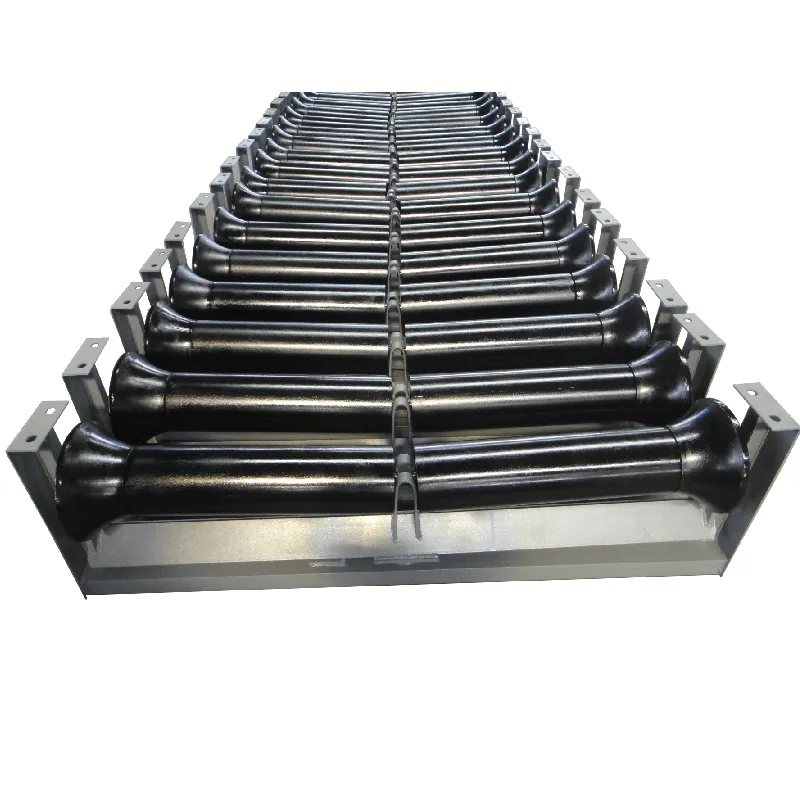

Conveyor systems play a pivotal role in modern material handling, making the choice of components like conveyor pulleys crucial for operational efficiency. A conveyor pulley is a cylindrical component used to support and drive conveyor belts. It is essential for ensuring the smooth and efficient transport of materials in various industries, including mining, manufacturing, and logistics. This article will delve into the key specifications and considerations when selecting conveyor pulleys.

Types of Conveyor Pulleys

Conveyor pulleys come in various types, each designed to serve specific functions within a conveyor system. The most common types include

1. Drive Pulleys These are used to transmit power to the conveyor belt, usually mounted on the conveyor system's drive shaft. 2. Idler Pulleys These help support the conveyor belt and maintain its alignment. They do not transmit power themselves but are critical for the belt's operation. 3. Tail Pulleys Positioned at the end of the conveyor, they help maintain tension on the belt and support the return side of the conveyor. 4. Take-Up Pulleys These are used to adjust the tension of the conveyor belt and are vital for maintaining its integrity and functionality.

Key Specifications

When considering conveyor pulley specifications, several factors come into play

1. Diameter The diameter of the pulley affects the belt's performance and its ability to handle various materials. Larger diameters can improve belt life, reduce spillage, and enhance material handling efficiency. However, they require more space and can be heavier.

2. Width The width of the pulley should match the width of the conveyor belt to avoid misalignment and ensure proper material transport. It plays a significant role in the load-carrying capacity of the conveyor system.

conveyor pulley specification

3. Material Conveyor pulleys are typically made from steel, aluminum, or plastic. Steel pulleys are the most common due to their strength and durability, while aluminum and plastic may be used for lighter applications or specific environments where corrosion resistance is needed.

4. Shell Thickness The thickness of the pulley shell impacts its strength and durability. Thicker shells can withstand higher loads and resist deformation, making them suitable for heavy-duty applications.

5. Bearing Type Bearings are crucial for the pulley’s operation, affecting its longevity and maintenance requirements. Common bearing types include sealed ball bearings, spherical roller bearings, and plain bearings. The choice depends on load capacity, speed, and environmental conditions.

6. Coatings and Finishes Surface treatments, such as galvanization or painting, can enhance the life span of a conveyor pulley, especially in harsh environments. These coatings protect against corrosion and wear, extending the operational lifespan.

Performance and Safety Considerations

Choosing the right conveyor pulley is not only about specifications but also performance. Factors like load capacity, speed, and the material being transported should be analyzed to ensure optimal operation. Moreover, it is essential to adhere to safety standards and regulations, as improperly specified or installed pulleys can lead to system failures and safety hazards.

Conclusion

In conclusion, understanding conveyor pulley specifications is vital for anyone involved in the design, maintenance, or operation of conveyor systems. By taking into account factors such as type, diameter, width, material, bearing type, and coatings, users can select the most appropriate pulleys for their specific applications. This careful selection will lead to improved efficiency, reduced maintenance costs, and a safer working environment, ultimately enhancing the productivity of the entire operation.

-

Taper Centering Idler Set for Conveyor SystemsNewsJun.25,2025

-

Small Idler Rollers for Industrial ConveyorsNewsJun.25,2025

-

Guide Training Idler Set for Conveyor MaintenanceNewsJun.25,2025

-

Friction Offset Idler Set for Industrial UseNewsJun.25,2025

-

Double-Center-Roller Idler AlignmentNewsJun.25,2025

-

Channel Inset Impact Troughing Idler Set for Heavy LoadsNewsJun.25,2025