Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor mounting brackets

Understanding Conveyor Mounting Brackets Importance, Types, and Applications

In the industrial world, efficiency and precision are paramount. Conveyor systems play a critical role in manufacturing and logistics, facilitating the smooth movement of materials and products. A crucial component of these systems is the mounting bracket. Conveyor mounting brackets aid in the secure installation and support of conveyor belts, helping to ensure that operations run smoothly and without interruption. In this article, we will delve into the importance of conveyor mounting brackets, explore their various types, and discuss their applications.

Importance of Conveyor Mounting Brackets

Conveyor mounting brackets are integral to the stability and functionality of conveyor systems. They serve multiple purposes

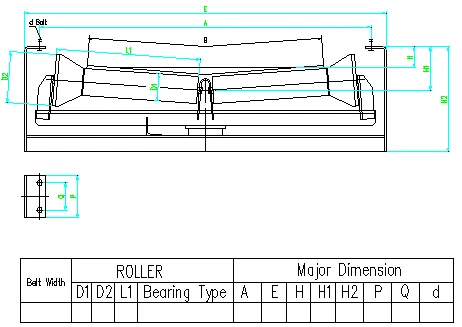

1. Support Mounting brackets provide the necessary support for conveyor components like belts, rollers, and drives. They help maintain the correct alignment and prevent vibrations that could lead to wear and tear over time.

2. Adjustment Many brackets offer features that allow for the adjustment of conveyor height and angle, ensuring that the system can be tailored to specific operational needs. This adjustability is crucial for maintaining optimal performance in varied manufacturing settings.

3. Space Management In crowded factory settings, space is often at a premium. Mounting brackets can be designed to optimize space usage, allowing conveyors to fit into tighter areas, thereby improving overall workflow.

4. Safety A properly mounted conveyor not only enhances efficiency but also contributes to workplace safety. Brackets that secure components in place minimize the risk of accidents associated with loose parts or misaligned equipment.

5. Durability High-quality mounting brackets are constructed from robust materials, ensuring longevity. This durability is essential for reducing maintenance needs and enhancing the overall reliability of the conveyor system.

Types of Conveyor Mounting Brackets

There are several types of conveyor mounting brackets, each designed according to specific requirements. Some common types include

1. U-Brackets These are often used in simple conveyor designs to secure belts and rollers. Their shape allows for easy installation and maintenance.

2. L-Brackets L-brackets offer a sturdy way to mount conveyors against walls or other structures. Their design provides strong support and can be used in both horizontal and vertical applications.

conveyor mounting brackets

3. Adjustable Brackets These brackets come with settings that allow users to change their position easily. They are ideal for applications where height or angle adjustments are frequently required.

4. Heavy-duty Brackets Designed for larger conveyor systems, heavy-duty brackets are built to withstand significant weight and pressure. They are used in heavy manufacturing and logistics environments.

5. Custom Brackets For unique applications, custom solutions can be engineered. These are tailored specifically to meet the operational needs and physical constraints of the facility.

Applications of Conveyor Mounting Brackets

Conveyor mounting brackets are utilized across a range of industries, showcasing their versatility. Some key applications include

1. Manufacturing In factories, they help transport products through various stages of production efficiently, from assembly to packaging.

2. Warehousing Conveyor systems in warehouses rely heavily on mounting brackets to facilitate the movement of goods. Properly installed brackets ensure that the system can handle varying loads and speeds without failure.

3. Food Processing Hygiene and stability are crucial in food processing environments. Conveyor mounting brackets made from food-safe materials help ensure compliance with safety regulations while maintaining effective production lines.

4. Automotive In automotive manufacturing, conveyor systems must operate under demanding conditions. Heavy-duty mounting brackets withstand the rigors of heavy parts transport while maintaining precise alignment.

5. Distribution Conveyor systems in distribution centers rely on robust mounting solutions to ensure efficiency in moving products to various locations, particularly in e-commerce.

Conclusion

In conclusion, conveyor mounting brackets are significant components that contribute to the efficacy, safety, and longevity of conveyor systems across various industries. Understanding the different types and their specific applications can help businesses optimize their operations, ensuring that materials flow seamlessly while minimizing the risk of downtime. Selecting the right mounting brackets can not only enhance operational efficiency but also promote a safer workplace, ultimately driving productivity and success in industrial environments.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025