Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu High-Quality Conveyor Belt Roll – Durable Rubber Conveyor Belt Rollers & Various Types for Industry

- Introduction: The Importance of Conveyor Belt Roll

- Technical Advantages of Modern Conveyor Belt Rollers

- Types of Conveyor Belt Rollers Explained

- Comparing Leading Manufacturers

- Customization Solutions for Specific Industries

- Application Case Studies and Real-World Impact

- Conclusion: Enhancing Efficiency with Conveyor Belt Roll Solutions

(conveyor belt roll)

Introduction: The Importance of Conveyor Belt Roll

Conveyor belt roll systems are fundamental components in countless industrial sectors. Responsible for facilitating the efficient movement of goods, raw materials, and products throughout manufacturing, mining, agriculture, and logistics operations, these rolls are essential for the automation of conveying lines. Recent reports from Statista reveal the global conveyor system market exceeded USD 7 billion in 2023 and projects steady growth as industries invest in increased automation and efficiency. Among the various elements of these systems, the quality and performance of each conveyor belt roll

are pivotal—directly impacting operational uptime, safety, and long-term costs. These seemingly simple rolls are complex engineering achievements that form the backbone of bulk material handling worldwide.

Technical Advantages of Modern Conveyor Belt Rollers

The evolution of conveyor belt roll technology is marked by significant technical advances. Innovations such as anti-corrosive coatings, precision bearings, modular assembly designs, and advanced rubber compounds have enhanced performance and longevity. According to industry research, high-quality rubber conveyor belt rollers can reduce maintenance intervals by up to 40% compared to traditional steel rollers. This is partly due to improved resistance to abrasion, chemical exposure, and temperature extremes. For instance, polyurethane-coated rollers are being adopted in food and pharmaceutical sectors due to their non-contaminating properties and lower friction coefficients—delivering not only operational reliability but also energy savings. The implementation of smart monitoring technology, such as IoT-enabled sensors, allows real-time condition tracking, predicting roller wear and prompting scheduled maintenance, thus maximizing productivity and minimizing unplanned downtime.

Types of Conveyor Belt Rollers Explained

Selecting the right type of roller is crucial for matching conveyor systems to the demands of their operation. There are several types of conveyor belt rollers commonly employed across industries:

- Plain or Flat Rollers: Utilized primarily in transporting flat-bottomed loads. Their simple construction ensures reliability under standard conditions.

- Impact Rollers: Positioned at loading zones where the impact of incoming materials is highest. Impact rollers generally feature shock-absorbing rubber discs to prolong service life and protect the belt.

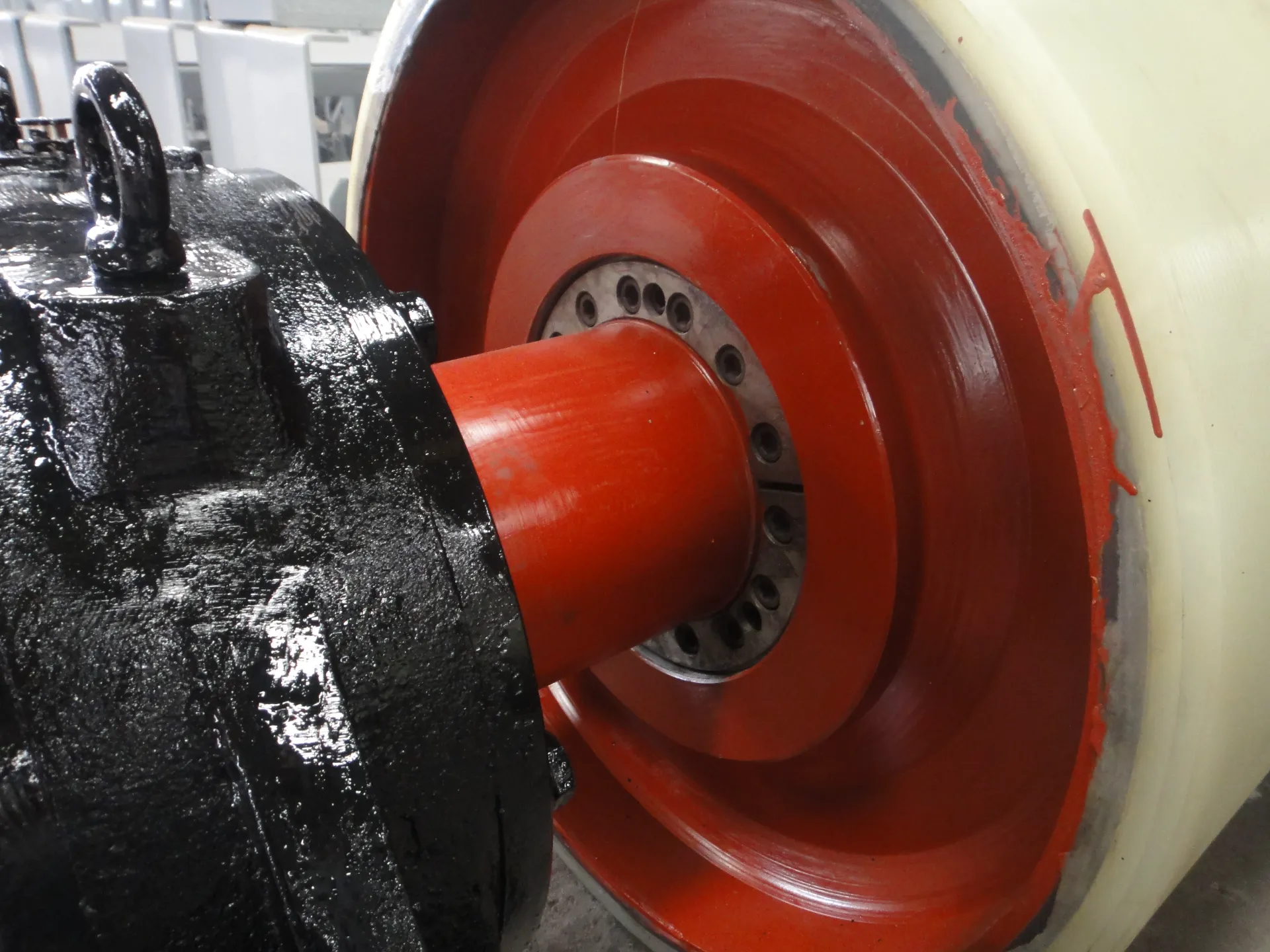

- Rubber-Coated Rollers: Applied in environments requiring superior grip or when handling delicate materials. The rubber exterior minimizes noise and belt slippage.

- Guide Rollers: Installed to direct and center the belt, especially on long or inclined runs; these prevent misalignment and reduce wear.

- Return Rollers: Located below the system to support the return side of the conveyor belt, often equipped with unique geometries for effective operation.

Understanding the specific functions and relative advantages of each type ensures optimal conveyor performance, safety, and cost management.

Comparing Leading Manufacturers

The choice of supplier can profoundly affect the service life and reliability of conveyor systems. Here is a comparative table featuring leading global manufacturers, highlighting critical performance and service criteria as evaluated in independent 2023 market research.

| Manufacturer | Roller Type Range | Average Lifespan (years) | Warranty (years) | Lead Time (weeks) | Certifications | Notable Clients |

|---|---|---|---|---|---|---|

| Interroll Group | Standard, Impact, Rubber-coated, Guide | 8 - 10 | 3 | 4 - 8 | ISO 9001, FDA | DHL, Amazon |

| Fastrax Conveyor Rollers | Steel, Plastic, Stainless, PVC | 6 - 8 | 2 | 2 - 6 | ISO 9001 | Tesco, Boots UK |

| Rulmeca Group | Bulk Handling, Rubber, Guide, HDPE | 9 - 12 | 5 | 7 - 12 | ISO 14001, ATEX | thyssenkrupp, Lafarge |

| PROK | Composite, Steel, Rubber Impact | 10 - 13 | 4 | 3 - 8 | ISO 45001 | BHP, Rio Tinto |

| Kinder Australia | Impact, Return, Rubber-Coated | 7 - 9 | 2 | 3 - 9 | ISO 9001 | Glencore, Fortescue |

From the analysis, manufacturers offering tailored solutions and extended warranties tend to secure contracts with high-profile, efficiency-demanding clients in mining, logistics, and manufacturing. Factors like product range, certifications, and lead times also play decisive roles when selecting a partner.

Customization Solutions for Specific Industries

No two industrial processes are identical, making customization vital to extracting maximum value from roller-integrated conveyor layouts. Manufacturers provide a wide variety of services beyond basic supply, including bespoke roller diameters (from 30mm up to 400mm), axle load capacities (up to 5,000 kg per roller), and surface treatments tailored to unique material handling challenges. For the mining sector, abrasion resistance and dust sealing are often prioritized, with custom labyrinth seals and heavy-duty bearing configurations. Food processors may require FDA-approved, food-safe polymers and water-resistant magnetic bearings. In the logistics industry, high-speed conveyors utilize lightweight composite rollers to reduce frictional drag and cycle times. According to a 2022 industry survey, over 62% of factories now invest in at least one custom roller solution per conveyor line to address challenges in throughput, environmental compliance, and safety.

Application Case Studies and Real-World Impact

Real-world deployment underlines the transformative power of advanced conveyor belt rolls:

- Mining (Australia): A major gold mining operation, confronting excessive downtime from roller failure, adopted reinforced rubber conveyor belt rollers with dust-sealed bearings. The result: downtime was reduced by 33% and belt replacement frequency decreased by over 22% within the first 12 months.

- Logistics (Germany): An e-commerce fulfillment center faced frequent belt misalignment. Installing advanced guide rollers with IoT sensors enabled automatic adjustment and predictive maintenance scheduling, boosting operational availability above 99%.

- Food Processing (USA): After implementing non-stick, antimicrobial rubber-coated rollers, a leading snack producer recorded a 17% increase in hygiene compliance scores and a marked reduction in unplanned line halts due to buildup.

- Cement (India): A cement plant utilizing heavy-duty impact rollers under primary hoppers extended primary maintenance cycles from three to five months, cutting annual maintenance costs by 15%.

These examples confirm that strategic upgrades in roller specification and technology can yield substantial improvements in efficiency, maintenance, safety, and ROI across diverse sectors.

Conclusion: Enhancing Efficiency with Conveyor Belt Roll Solutions

The right conveyor belt roll is a catalyst for industrial productivity. As analytical data and field experience show, investments in premium rubber conveyor belt rollers and the appropriate types of conveyor belt rollers lead to sustained operational excellence. The integration of smart technology, custom engineering, and close collaboration with proven manufacturers empowers organizations to streamline processes, minimize costs, and adapt rapidly to evolving demands. By focusing on advanced roller solutions that align with unique facility requirements, companies can confidently face future automation challenges with resilience and efficiency.

(conveyor belt roll)

FAQS on conveyor belt roll

Q: What is a conveyor belt roll?

A: A conveyor belt roll is a cylindrical, rolled-up length of conveyor belt material. It is typically used for transportation, storage, or easy installation on conveyor systems.Q: What are rubber conveyor belt rollers used for?

A: Rubber conveyor belt rollers support and guide the belt during operation, reducing wear and noise. They are ideal for handling delicate or lightweight materials.Q: What are the common types of conveyor belt rollers?

A: Common types include carrying rollers, impact rollers, and return rollers. Each type serves a specific function in supporting and protecting the conveyor belt system.Q: How do you install a conveyor belt roll onto a conveyor system?

A: The conveyor belt roll is carefully unwound and aligned onto the pulleys of the conveyor. Proper tension and alignment are essential for optimal performance.Q: What are the advantages of using rubber conveyor belt rollers?

A: Rubber rollers absorb shocks and reduce conveyor system noise. They also provide better grip and protect both the belt and transported items from damage.-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025