Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Understanding Bend and Snub Pulleys in Mechanical Systems and Their Applications

Understanding Bend and Snub Pulleys in Mechanical Systems

Pulleys are essential components in various mechanical systems, playing a vital role in transferring force and motion. Among the different types of pulleys, bend pulleys and snub pulleys hold particular significance. Each serves unique functions, and understanding their applications is crucial for designing effective mechanical systems.

Bend Pulleys

Bend pulleys are primarily used to guide and redirect the motion of belts or cables in a mechanical system. They are designed to create a change in direction for tensioned belts, allowing for a more compact arrangement of machinery. Commonly found in conveyor systems, elevators, and industrial machinery, bend pulleys can effectively manage the layout of components while maintaining optimal performance.

One of the key attributes of bend pulleys is their ability to help adjust the length of the belt path. This adjustment is particularly useful in applications where space is limited, as it allows engineers to design systems that can operate efficiently within confined areas. Additionally, bend pulleys can reduce the wear and tear on belts by smoothly guiding their motion, minimizing friction and stress.

Bend pulleys are typically characterized by their radius, which determines how sharply a belt can be turned. A larger radius reduces stress on the belt, increasing its longevity and reliability. Conversely, tighter bends can lead to increased wear, necessitating careful consideration of the pulley size and placement during system design.

Snub Pulleys

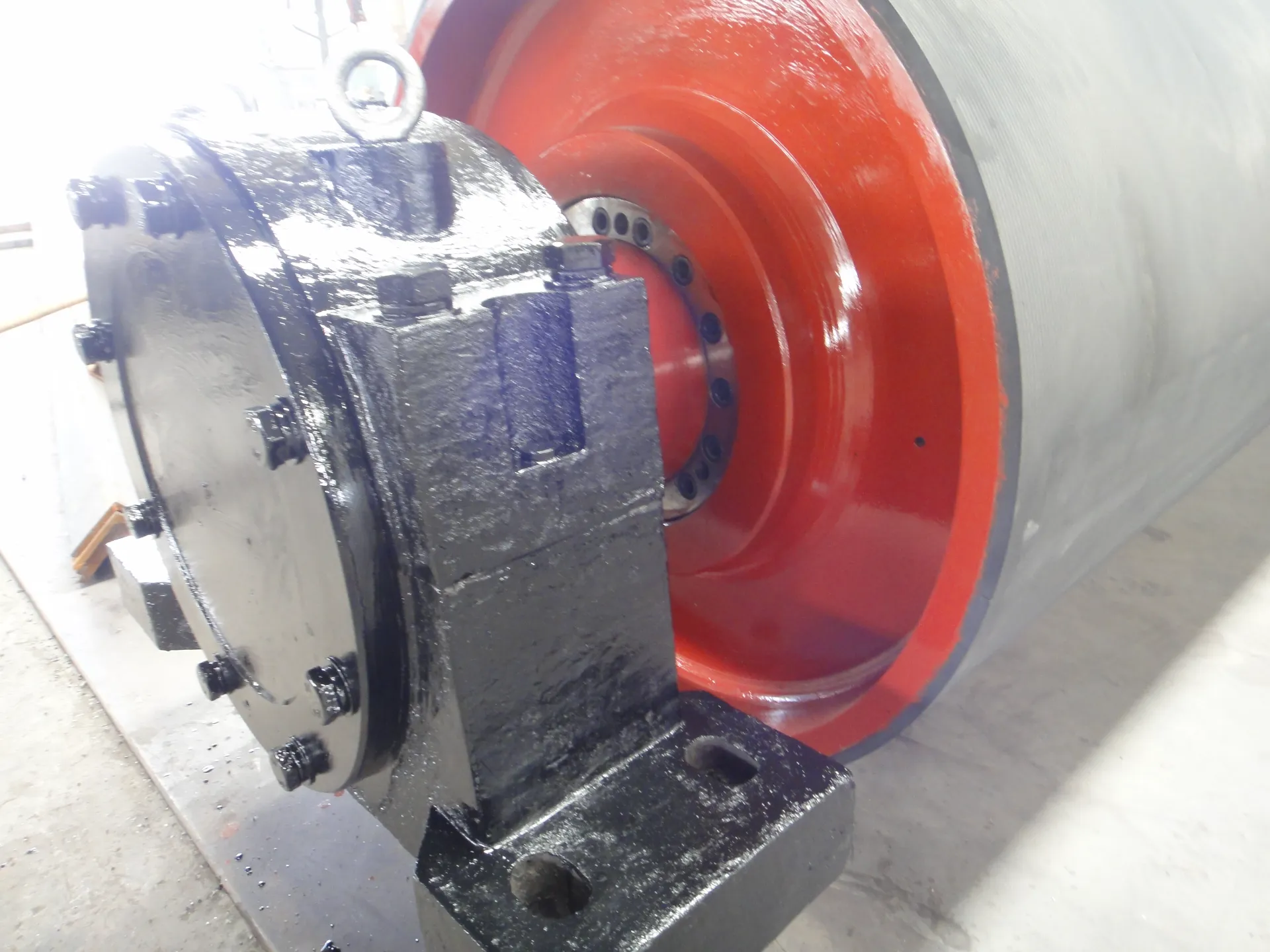

bend pulley and snub pulley

Snub pulleys, on the other hand, serve a different purpose. They are specifically designed to increase the wrap angle of a belt around a drive pulley. By doing this, snub pulleys enhance the friction between the belt and the drive, allowing for better power transmission. This increased grip is critical in applications where higher torque or load capacity is required.

Another significant benefit of snub pulleys is their role in tensioning systems. By adjusting the position of a snub pulley, engineers can effectively manage belt tension, which is crucial for ensuring the longevity and efficiency of the system. Proper tension maintains optimal belt operation and reduces slippage, which can cause loss of power and efficiency.

Snub pulleys are often used in combination with other pulleys in a pulley system. For instance, they can be strategically placed near drive pulleys to maximize their effectiveness. In settings like automotive engines, where precision and reliability are paramount, snub pulleys can play a crucial role in ensuring that the entire system operates smoothly.

Conclusion

In summary, both bend pulleys and snub pulleys are vital components in mechanical systems, each possessing unique characteristics that contribute to overall efficiency and performance. Bend pulleys excel in guiding and redirecting belt motion, allowing for streamlined designs and reduced wear on belts. Snub pulleys, conversely, are instrumental in enhancing belt grip and tension management, which is essential for applications requiring robust power transmission.

When designing mechanical systems, engineers must consider the placement and specifications of these pulleys to achieve optimal performance. Understanding the dynamics of bend and snub pulleys not only enhances the functionality of different systems but also contributes to their reliability and durability. As technology advances and new applications emerge, the roles of these pulleys will continue to evolve, leading to even more innovative solutions in the field of mechanical engineering.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025