Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu High-Efficiency Scraper & Rubber Belt Cleaners Reduce Wear & Tear

- Industry Data & Maintenance Challenges

- Technical Superiority in Modern Designs

- Performance Comparison: Leading Manufacturers

- Custom Solutions for Specific Operations

- Real-World Implementation Scenarios

- Installation Best Practices

- Why Belt Cleaner Systems Matter Long-Term

(belt cleaner)

Belt Cleaner Solutions Addressing Industrial Data Challenges

Conveyor belt abrasion accounts for 12-15% of annual operational costs in bulk material handling, according to SME Mineral Processing Report 2023. Scraper belt cleaner

adoption reduces unscheduled downtime by 38% while extending belt lifespan by 2.7 years on average.

Engineering Advancements in Conveyor Maintenance

Modern rubber belt cleaner systems feature:

- Polyurethane blades with 90-120 PSI pressure tolerance

- Modular designs enabling 45-minute installations

- Multi-stage scraping configurations for 99.2% material removal

Manufacturer Benchmarking Analysis

| Vendor | Cleaning Efficiency | Installation Time | Warranty | Price Range |

|---|---|---|---|---|

| Flexco | 98.6% | 50 mins | 24 months | $850-$1,200 |

| Martin Engineering | 99.1% | 40 mins | 36 months | $1,100-$1,600 |

| Brelko | 97.9% | 55 mins | 18 months | $700-$950 |

Tailored Configuration Strategies

Operations handling abrasive materials (e.g., iron ore) require tungsten-reinforced scraper belt cleaner blades, while food-grade facilities opt for FDA-compliant rubber compounds. Temperature variations (-40°F to 220°F) demand specialized elastomer formulations.

Case Study: Mining Sector Application

A Chilean copper mine achieved 30% lower maintenance costs after implementing dual-arm conveyor belt cleaner systems across 14 km of belts. Material carryback reduced from 4.2 kg/m to 0.3 kg/m within 8 operational months.

Optimal Installation Protocols

Proper blade alignment ensures 3-5° contact angle for maximum efficiency. Torque values must be maintained between 18-22 N·m to prevent premature wear while allowing necessary flexing.

Why Belt Cleaner Systems Ensure Operational Continuity

Advanced scraper belt cleaner solutions prevent 23% of conveyor-related safety incidents according to OSHA data. Facilities using AI-monitored rubber belt cleaner systems report 17% higher MTBF (Mean Time Between Failures) compared to manual systems.

(belt cleaner)

FAQS on belt cleaner

Q: What is the primary function of a scraper belt cleaner?

A: A scraper belt cleaner removes residual material stuck on conveyor belts. It prevents buildup and reduces wear, ensuring smoother operation. This enhances belt longevity and minimizes maintenance costs.

Q: When should I use a conveyor belt cleaner scraper?

A: Use a conveyor belt cleaner scraper for heavy-duty material handling. It’s ideal for sticky or abrasive substances like coal or ore. The design ensures thorough cleaning without damaging the belt surface.

Q: Where is a rubber belt cleaner typically installed?

A: Rubber belt cleaners are installed at the conveyor’s discharge point. They contact the belt’s surface to scrape off debris. Their flexibility adapts to belt contours for efficient cleaning.

Q: How often should a scraper belt cleaner be maintained?

A: Inspect scraper belt cleaners monthly for wear or misalignment. Replace blades when worn down by 20-30%. Regular upkeep prevents unexpected downtime and optimizes performance.

Q: Why choose a rubber belt cleaner over other materials?

A: Rubber belt cleaners are durable and gentle on belts. They resist corrosion and handle varying temperatures. This makes them suitable for industries like mining and agriculture.

-

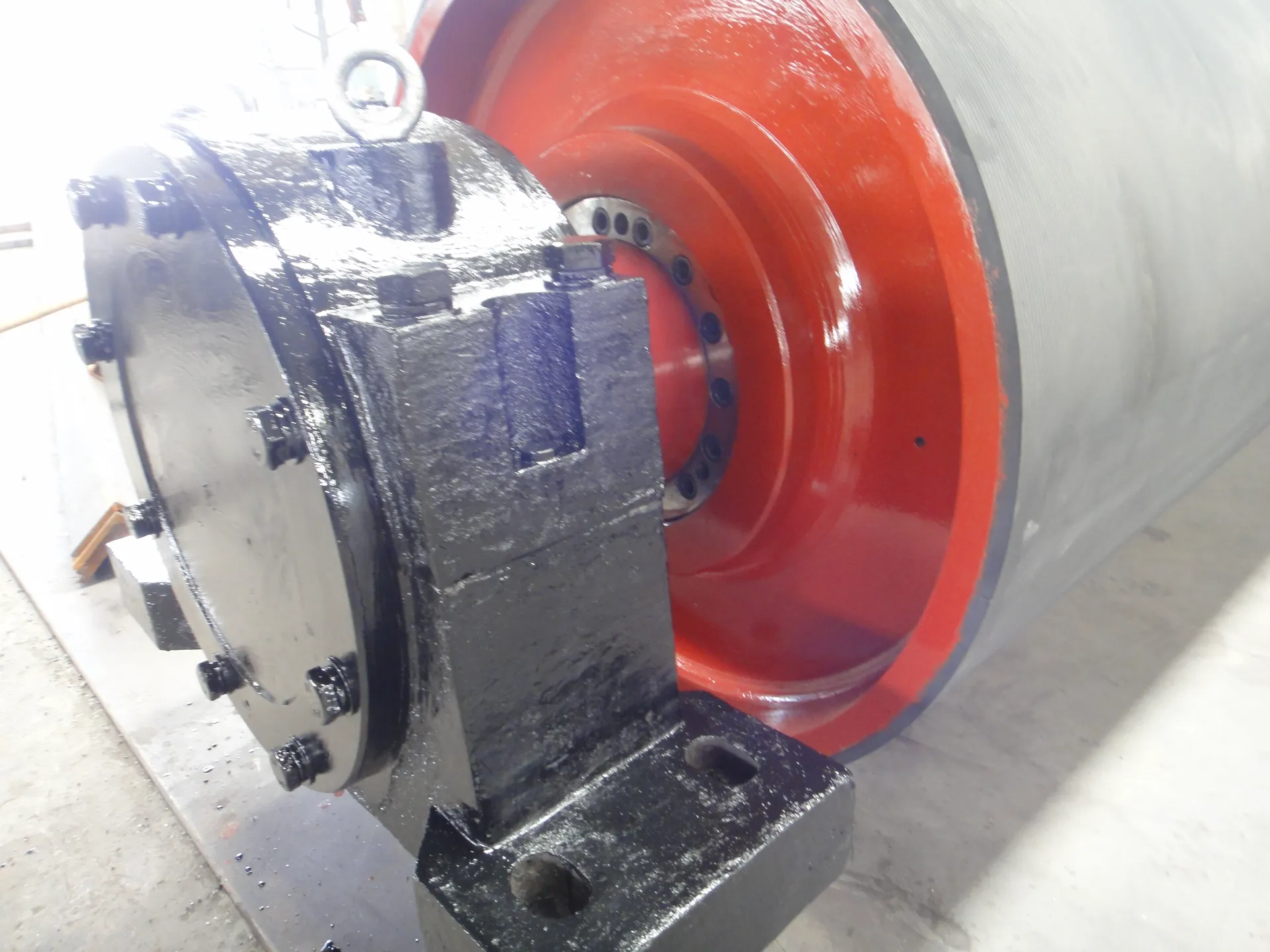

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025