Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Optimizing Conveyor Systems with Trough Idler Rollers for Enhanced Efficiency

Understanding Trough Idler Rollers Essential Components in Conveyor Systems

Trough idler rollers are critical components in conveyor systems, widely used across various industries, including mining, agriculture, and manufacturing. Their primary function is to support the conveyor belt and facilitate the transportation of materials in a safe and efficient manner. Understanding the role and design of trough idler rollers can enhance operational efficiency, reduce maintenance costs, and improve safety in material handling processes.

The Design and Functionality of Trough Idler Rollers

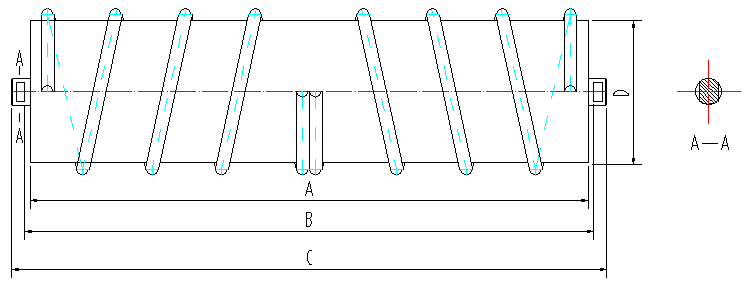

Trough idler rollers are designed to maintain the conveyor belt in a trough or curved shape, which helps prevent material spillage while enabling the transportation of bulk materials. Typically, these rollers are mounted at an angle, forming a ‘V’ shape, which allows them to cradle the belt securely. The design of these rollers contributes significantly to the belt's tracking, helping it stay aligned and preventing misalignment that could lead to wear or damage.

These rollers come in various sizes and configurations, including impacted, rubberized, or steel-coated options, depending on the material being conveyed and environmental conditions. The choice of material and design impacts the durability, weight capacity, and overall performance of the conveyor system.

Benefits of Using Trough Idler Rollers

One of the primary advantages of using trough idler rollers is their ability to minimize material spillage

. The design allows for effective containment of materials, which is particularly crucial in industries where bulk materials such as coal, gravel, or ore are transported. This containment reduces the risk of product loss and minimizes the environmental impact often associated with spillage.trough idler rollers

Moreover, implementing trough idler rollers can help in maintaining the belt's tension. Proper roller alignment ensures that the belt remains taut, reducing the chances of sagging, which can lead to excessive wear and energy consumption. By facilitating a smoother operation, these rollers contribute to improved energy efficiency across conveyor systems, leading to lower operational costs.

Maintenance Considerations

Despite their robust design, trough idler rollers require regular maintenance to ensure optimal performance. Routine inspections are critical for identifying wear and tear, particularly on the bearings and surfaces of the rollers. Lubrication is often necessary to minimize friction and prevent overheating, which can be detrimental to both the rollers and the belt.

Additionally, operators should be vigilant about debris accumulation around the rollers, as this can impede their functionality. Regular cleaning and timely replacement of damaged rollers are essential for maintaining the overall integrity of the conveyor system.

Conclusion

In conclusion, trough idler rollers play a pivotal role in the efficiency and safety of conveyor systems used for transporting bulk materials. Their design fosters effective material containment while ensuring the smooth operation of conveyor belts. By investing in quality trough idler rollers and adhering to maintenance best practices, industries can enhance their material handling processes, optimize performance, and reduce costs associated with downtime and maintenance. As technology progresses, further innovations in the design and functionality of these rollers will continue to shape the future of conveyor systems, addressing the ever-growing demands of various sectors. Adopting advanced designs can lead to increased reliability and efficiency, ensuring that trough idler rollers remain a fundamental component in the world of material handling.