Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Februari . 08, 2025 02:34

Back to list

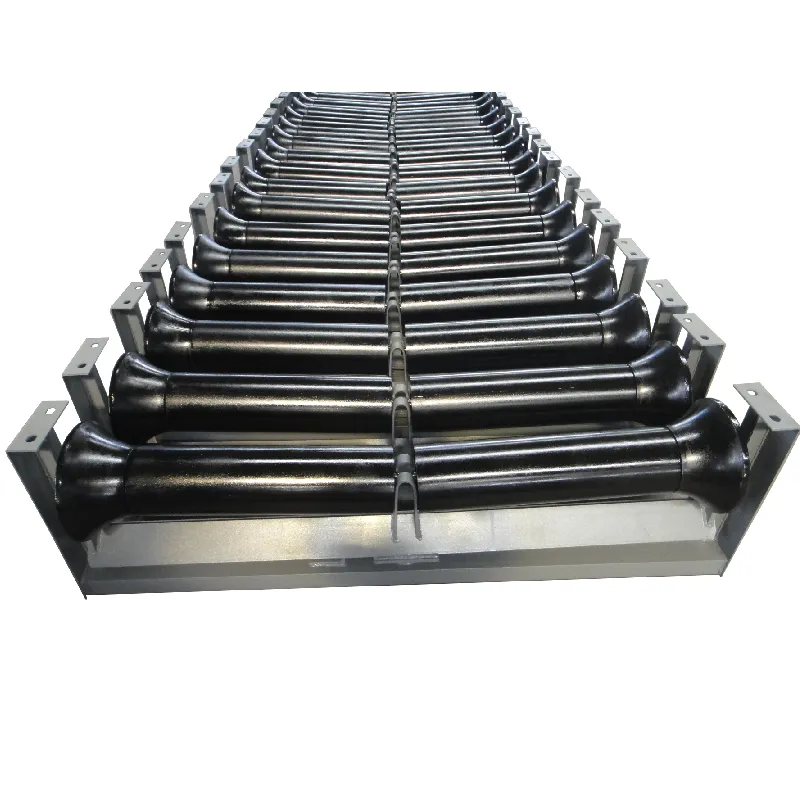

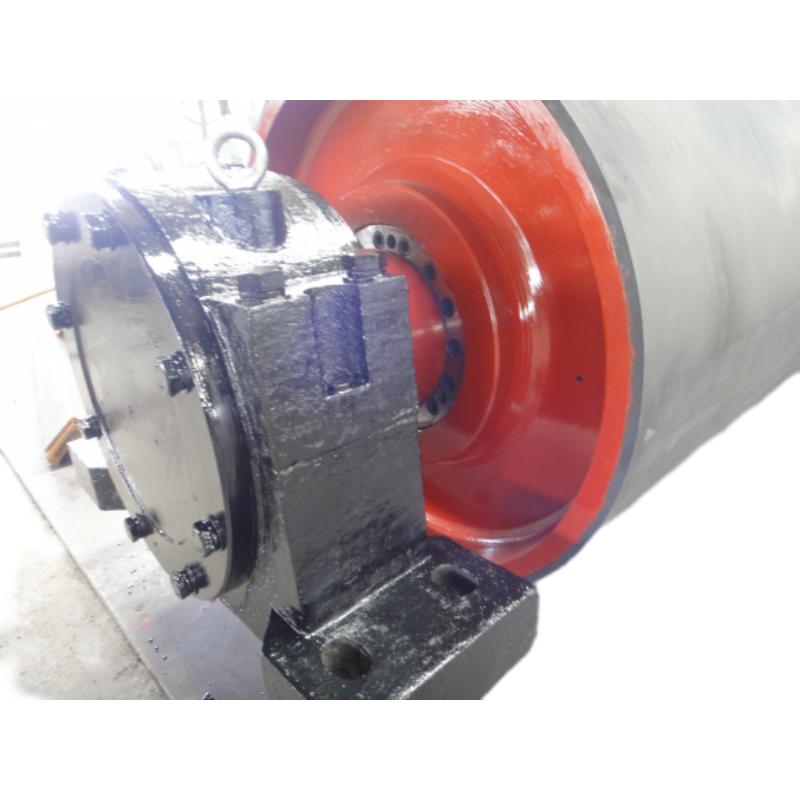

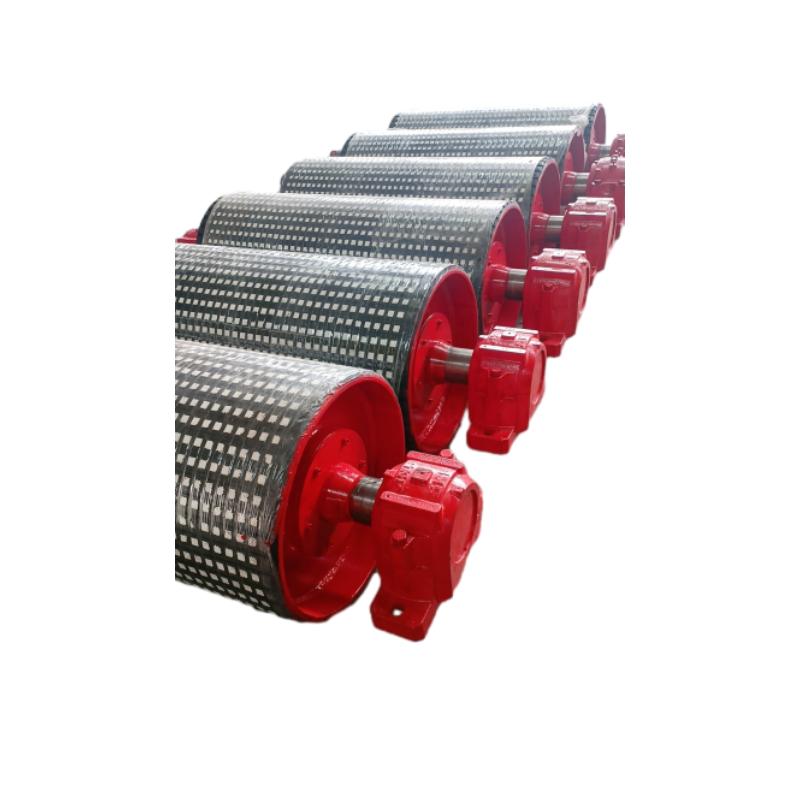

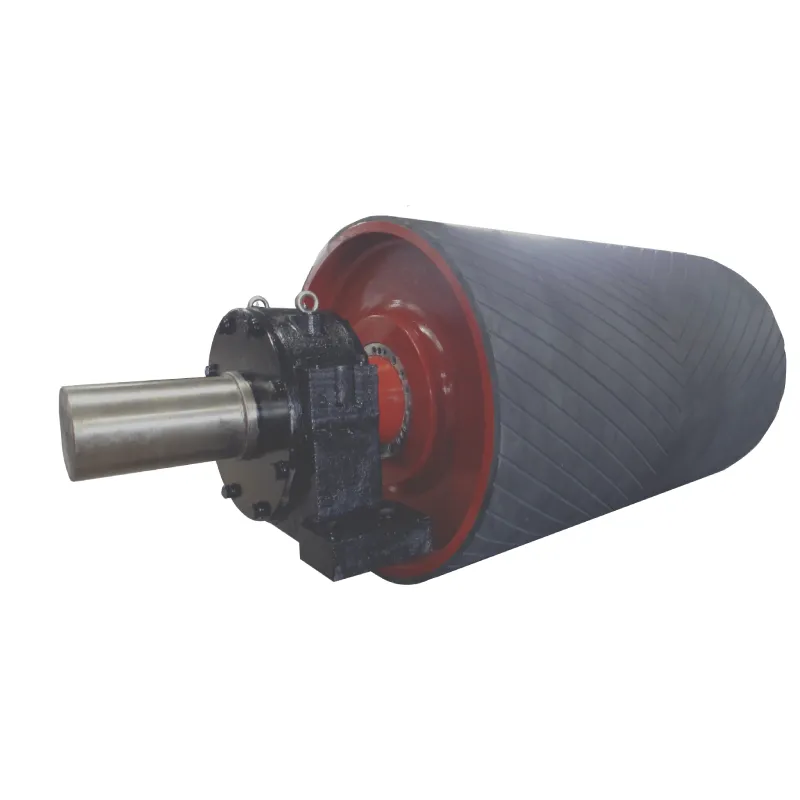

conveyor pulley components

In the ever-evolving world of material handling and conveyor systems, conveyor pulley components play a crucial role in ensuring the smooth operation and longevity of these systems. As an expert in industrial equipment optimization, let me delve into the significant aspects that underscore their importance, drawing from professional experience and authoritative knowledge in the field.

Pulley lagging, often overlooked, is integral to increasing traction and reducing slippage between the belt and the pulley. By selecting the right type of lagging, whether it be ceramic or rubber, based on the operational environment, wear resistance and energy efficiency can be markedly improved. A well-implemented pulley lagging not only enhances the grip but also acts as a protective layer, prolonging the life of the pulley components. A comprehensive understanding of these components highlights the need for a strategic approach to maintenance and upgrades. Regular inspection routines must be part of the operational protocol, focusing on identifying signs of wear and misalignment. Leveraging technological advancements such as thermal imaging and ultrasonic testing can offer timely insights into the health of conveyor pulley components, thus preventing major failures. Professional expertise also emphasizes the importance of selecting components from reputable manufacturers known for their rigorously tested products. This decision goes beyond mere compliance with industry standards; it is about aligning with partners whose commitment to quality and innovation serves as a cornerstone for your operational success. Trust in the reliability and performance of conveyor systems is non-negotiable. By investing in high-quality conveyor pulley components and following expert-guided maintenance practices, businesses can achieve optimal throughput and reduced operational risks. Moreover, fostering an environment of continuous learning and adaptation to new technologies and methodologies will ensure that conveyor systems remain at the cutting edge of efficiency and dependability. The nuanced understanding of conveyor pulley components, backed by real-world application and technical expertise, not only elevates the operational standards but also sets the foundation for industrial excellence, serving as a testament to the strategic foresight and commitment to quality that defines successful material handling operations.

Pulley lagging, often overlooked, is integral to increasing traction and reducing slippage between the belt and the pulley. By selecting the right type of lagging, whether it be ceramic or rubber, based on the operational environment, wear resistance and energy efficiency can be markedly improved. A well-implemented pulley lagging not only enhances the grip but also acts as a protective layer, prolonging the life of the pulley components. A comprehensive understanding of these components highlights the need for a strategic approach to maintenance and upgrades. Regular inspection routines must be part of the operational protocol, focusing on identifying signs of wear and misalignment. Leveraging technological advancements such as thermal imaging and ultrasonic testing can offer timely insights into the health of conveyor pulley components, thus preventing major failures. Professional expertise also emphasizes the importance of selecting components from reputable manufacturers known for their rigorously tested products. This decision goes beyond mere compliance with industry standards; it is about aligning with partners whose commitment to quality and innovation serves as a cornerstone for your operational success. Trust in the reliability and performance of conveyor systems is non-negotiable. By investing in high-quality conveyor pulley components and following expert-guided maintenance practices, businesses can achieve optimal throughput and reduced operational risks. Moreover, fostering an environment of continuous learning and adaptation to new technologies and methodologies will ensure that conveyor systems remain at the cutting edge of efficiency and dependability. The nuanced understanding of conveyor pulley components, backed by real-world application and technical expertise, not only elevates the operational standards but also sets the foundation for industrial excellence, serving as a testament to the strategic foresight and commitment to quality that defines successful material handling operations.

Next:

Latest news

-

Taper Centering Idler Set for Conveyor SystemsNewsJun.25,2025

-

Small Idler Rollers for Industrial ConveyorsNewsJun.25,2025

-

Guide Training Idler Set for Conveyor MaintenanceNewsJun.25,2025

-

Friction Offset Idler Set for Industrial UseNewsJun.25,2025

-

Double-Center-Roller Idler AlignmentNewsJun.25,2025

-

Channel Inset Impact Troughing Idler Set for Heavy LoadsNewsJun.25,2025

OUR PRODUCTS