Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  Ingiriis

Ingiriis  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

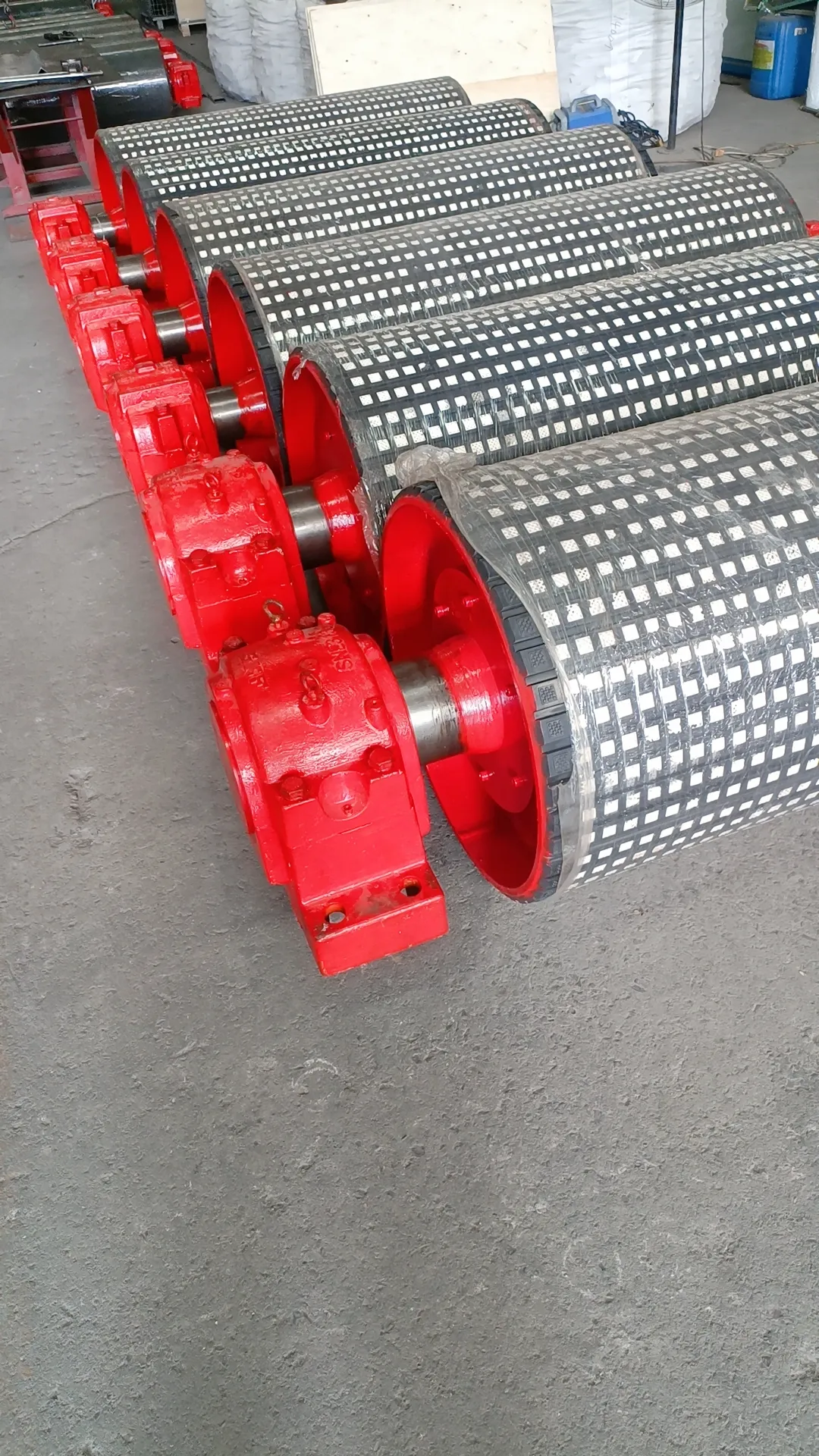

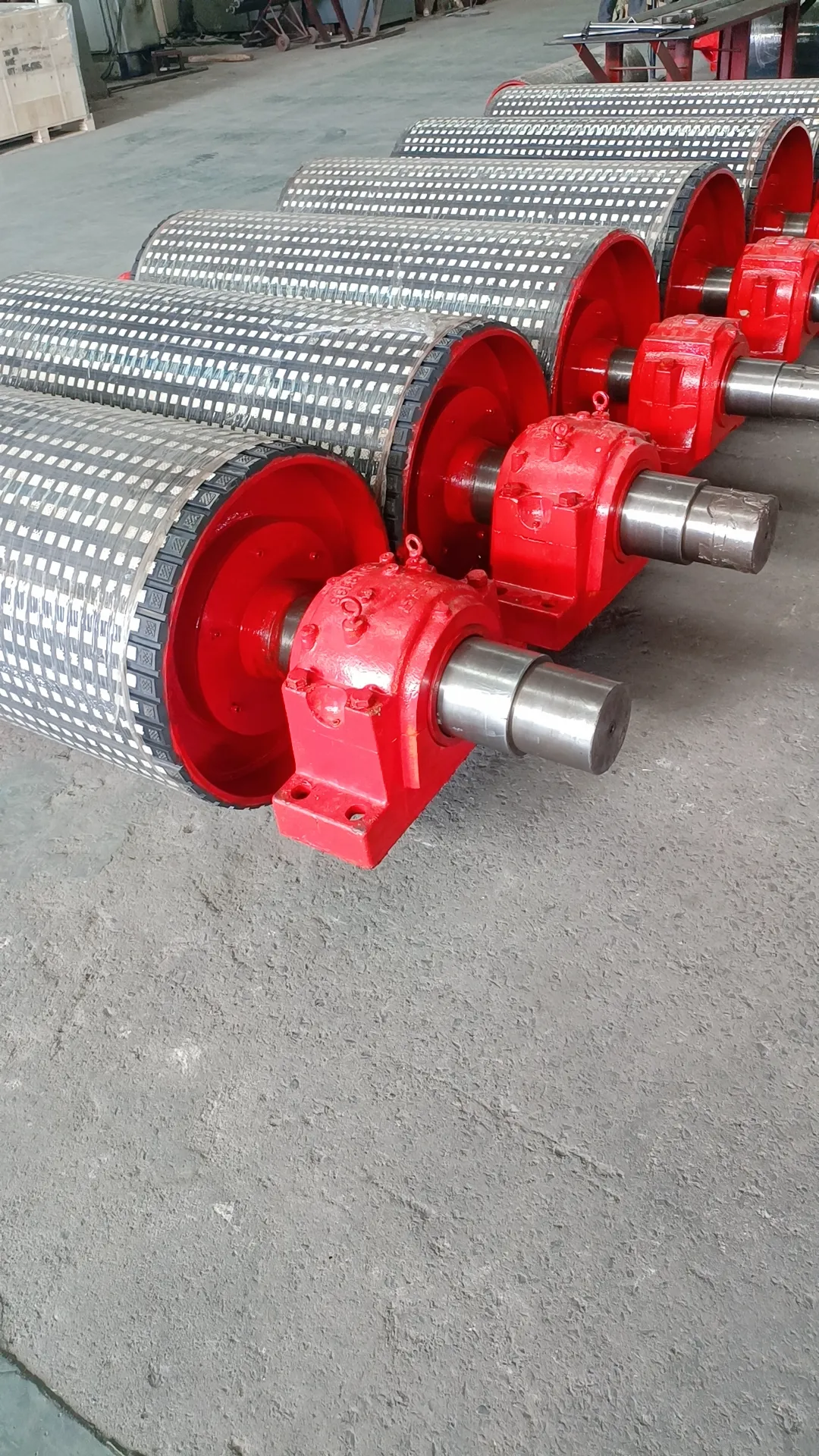

Zulu Ceramic Lagging Conveyor Pulley for Conveyor Belt Systems

Since its establishment in March 2007, Yanshan Aohua Machinery Equipment Manufacture Limited Company has been a dedicated innovator in the field of belt conveyor and parts&components research, development, manufacturing, and sales. Among our remarkable product offerings, ceramic lagging conveyor pulley stands out as a revolutionary solution for conveyor belt systems. These pulleys, featuring ceramic pulley technology, are engineered to transform the efficiency, durability, and performance of industrial material handling processes. In harsh operating environments where traditional pulleys may falter, ceramic pulley for conveyor proves to be a game - changer, offering superior wear resistance and longevity.

The Working Principle of Ceramic Lagging Conveyor Pulley

Exceptional Friction and Traction: The ceramic lagging on ceramic lagging conveyor pulley creates an incredibly high - friction surface. When the conveyor belt comes into contact with this pulley, the ceramic tiles provide a firm grip, preventing belt slippage even under heavy loads or in challenging conditions. This enhanced traction ensures that the belt moves smoothly and precisely, reducing the risk of misalignment and improving the overall stability of the conveyor system.

Unmatched Wear Resistance: One of the key advantages of ceramic pulley for conveyoris its outstanding wear resistance. Ceramic materials are extremely hard and durable, far surpassing traditional rubber or metal lagging. In industries where conveyor belts are constantly exposed to abrasive materials like rocks, ores, or sand, the ceramic pulley can withstand the harsh friction and impact. As a result, it outlasts ordinary pulleys by a significant margin. In fact, under the same operating conditions, the wear - resistance service life of the ceramic rubber pulley is 6 - 8 times that of the ordinary rubber pulley.

Versatile Applications of Ceramic Pulley

|

Industry |

Role of Ceramic Pulley |

|

Mining |

In the mining industry, conveyor systems face heavy and abrasive materials. Ceramic lagging conveyor pulley endures continuous impact and friction from transporting rocks, ores, and minerals with minimal wear. This ensures uninterrupted belt operation, reducing downtime for replacements and maintenance, and keeping the mining process flowing smoothly. |

|

Cement Production |

Cement plants handle fine, abrasive powders that quickly wear traditional pulleys. Ceramic pulley for conveyor offers excellent protection. The ceramic lagging resists abrasion from cement particles, maintaining pulley and belt integrity, increasing production efficiency, and cutting costs associated with frequent repairs and replacements. |

|

Power Generation |

In coal - fired power plants, conveyor systems are crucial for transporting coal to boilers. Ceramic lagging conveyor pulley withstands the constant flow of heavy, abrasive coal. The high - performance ceramic pulley ensures reliable belt operation, contributing to stable power generation. |

|

Metallurgy |

The metallurgy industry deals with high - temperature and heavy - duty materials. Ceramic pulley endures extreme conditions during metal processing, handling molten metals and ores with ease. The ceramic lagging protects the pulley from high - temperature and abrasive effects, ensuring continuous conveyor system operation. |

|

Chemical |

Chemical plants may transport corrosive materials. Ceramic pulley for conveyor resists both wear and chemical corrosion. The ceramic material is not easily eroded, safeguarding the pulley and ensuring safe, efficient chemical product transportation. |

|

Seaport |

Seaports handle diverse goods, including heavy containers and bulk materials. Ceramic lagging conveyor pulley withstands the harsh marine environment, such as saltwater spray and high humidity. Its superior traction ensures stable belt movement, improving port operation efficiency. |

|

Hydropower |

In hydropower plants, materials like gravel and sand for dam construction or maintenance are transported. Ceramic pulley's wear - resistance allows it to handle these abrasive materials, ensuring smooth conveyor system operation in hydropower projects. |

|

Grain |

For grain handling, although materials are less abrasive, ceramic pulley's high - friction surface prevents belt slippage, ensuring accurate and efficient grain transportation. It also resists moisture and dust in the grain - handling environment. |

Installation and Maintenance of Ceramic Pulley

Professional Installation: Installing ceramic lagging conveyor pulleydemands specialized skills. Our experienced technicians at Yanshan Aohua Machinery Equipment Manufacture Limited Company ensure proper installation. They carefully handle the ceramic pulley for conveyor, making sure it is correctly aligned and securely mounted on the conveyor system. This professional installation is crucial for maximizing the performance and lifespan of the pulley.

Regular Maintenance Checks: Regular maintenance is essential to keep ceramic pulleyin top condition.

-

- Inspect the ceramic lagging for any signs of damage, such as cracks or loose tiles. Promptly repair or replace any damaged parts to prevent further issues. Use non - destructive testing methods like visual inspection or ultrasonic testing to detect internal cracks in the ceramic tiles.

- Check the pulley's alignment and rotation regularly. Use alignment tools to ensure the pulley is properly aligned with the conveyor belt, as misalignment can cause uneven wear on the belt and pulley. Ensure that the shaft and bearings are in good working order. Lubricate the bearings as per the recommended schedule to reduce friction and ensure smooth operation. Use high - quality lubricants suitable for the operating conditions of the pulley, and follow the lubrication procedures specified by the bearing manufacturer.

- Clean the pulley surface periodically to remove any accumulated debris or material buildup, which could affect its performance. Use appropriate cleaning agents and tools to avoid damaging the ceramic lagging during the cleaning process. For stubborn debris, use soft brushes or non - abrasive cleaning materials.

Ceramic Lagging Conveyor Pulley FAQS

How Does a Ceramic Lagging Conveyor Pulley Differ from a Traditional Rubber - Lagged Pulley?

Ceramic lagging conveyor pulley offers several key differences compared to traditional rubber - lagged pulleys. The ceramic pulley has a much higher wear - resistance, with its service life being 6 - 8 times that of an ordinary rubber pulley. The ceramic lagging provides superior friction and traction, reducing belt slippage more effectively. Additionally, ceramic materials are more resistant to chemical corrosion and extreme temperatures, making ceramic pulley for conveyor suitable for a wider range of harsh operating environments. Rubber - lagged pulleys may degrade quickly in high - temperature or chemically corrosive conditions, while ceramic pulleys maintain their performance and integrity.

Can Ceramic Pulley Be Used in High - Temperature Environments?

Yes, ceramic pulley is well - suited for high - temperature environments. Ceramic materials have excellent heat - resistance properties, allowing them to maintain their structural integrity and performance even at elevated temperatures. They can withstand temperatures that would cause rubber - lagged pulleys to melt or degrade. This makes ceramic lagging conveyor pulley an ideal choice for industries such as power generation and steel manufacturing, where high - temperature conditions are common. However, it's still important to ensure that the other components of the conveyor system, such as the bearings and shaft, are also suitable for high - temperature operation.

What Is the Recommended Lubrication Interval for Ceramic Pulley Bearings?

The recommended lubrication interval for the bearings of ceramic pulley for conveyor depends on the specific operating conditions. In general, for normal - duty applications, it is advisable to lubricate the bearings every 3 - 6 months. However, in more demanding environments with high loads, frequent starts and stops, or exposure to dust and debris, lubrication may be required every 1 - 3 months. Regular lubrication helps ensure smooth rotation of the pulley and extends the life of the bearings. It's important to use the type of lubricant recommended by the bearing manufacturer and follow the correct lubrication procedures to achieve the best results.

How Do I Deal with a Loose Ceramic Tile on the Pulley?

If you notice a loose ceramic tile on a ceramic lagging conveyor pulley, it is important to address the issue promptly. First, stop the conveyor system to ensure safety. Then, carefully remove the loose tile and clean the surface of the pulley where it was attached, using a suitable cleaning agent to remove any residue. After that, apply a high - quality adhesive specifically designed for ceramic materials, following the manufacturer's instructions. Press the tile firmly back into place and let the adhesive cure completely before restarting the conveyor. If the damage is extensive or you're unsure about the repair process, contact our professional technicians for assistance.

Are Ceramic Pulley Products Compatible with All Conveyor Belt Systems?

Our ceramic pulley products are designed to be compatible with a wide range of conveyor belt systems. However, compatibility also depends on factors such as belt width, load capacity, and the specific requirements of your conveyor system. For example, the pulley diameter and length need to match the belt's dimensions and the material - handling needs. Our technical team at Yanshan Aohua Machinery Equipment Manufacture Limited Company can provide personalized advice and assistance. By sharing details about your conveyor system, we can help you select the most suitable ceramic lagging conveyor pulley model, ensuring optimal performance and efficiency.

Ready to revolutionize your conveyor belt systems? Explore the high - performance ceramic lagging conveyor pulley, ceramic pulley for conveyor, and ceramic pulley products from Yanshan Aohua Machinery Equipment Manufacture Limited Company. Visit our official www.idleraohua.com today to view detailed product information, technical specifications, and discover how our innovative solutions can transform your industrial material handling processes!

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysWararkaJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsWararkaJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesWararkaJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysWararkaJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerWararkaJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersWararkaJul.22,2025