Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  Ingiriis

Ingiriis  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Gaadhida suunka Idler

Faahfaahinta

Faahfaahinta

Idlers are used to transport bulk materials. trough Angle: 10°, 20°, 30°, 35°, 45°, 60°, etc. which can also be manufactured according to customer requirements. The installation spacing is between 1000 and 1200mm. It can also be adjusted according to the specific requirements of users. The carrying idler consists of troughing idler, impact idler, suspension idler, and carrying aligning idler.

Tilmaamaha Alaabta

Tilmaamaha Alaabta

|

Faahfaahinta Alaabta |

Sharaxaada |

Adeegyada Dalbashada |

|

Magaca Alaabta: Gaadhiga suunka Idler |

Walaxda Frame: birta xagasha, Channel Steel, Dhuumaha birta |

Dalabka ugu yar: 1 gabal |

|

Magaca asalka ah: Gobolka Hebei, Shiinaha |

Heerka Alaabta:Q235B,Q235A |

Qiimaha: gorgortanka |

|

Magaca astaanta: AOHUA |

Dhumucda gidaarka: 6-12mm ama sida ku qoran amarada |

Xirxirida: Sanduuqa alwaaxyada ee aan qiiqa lahayn, jir bir ah, palette |

|

Heerka: CENA, ISO, DIN, JIS, DTII |

alxanka: alxanka gaaska isku dhafan |

Waqtiga bixinta: 10-15 maalmood |

|

Ballaca suunka:400-2400mm |

Habka alxanka: alxanka Robot |

Muddada Lacag-bixinta: TT, LC |

|

Waqtiga Nolosha: 30000 Saacadood |

Midabka:Madow, Cas, Cagaaran, Buluug, ama sida waafaqsan amarada |

Dekadda dhoofinta: Tianjin Xingang, Shanghai, Qingdao |

|

Dhumucda darbiga ee Roller:2.5 ~ 6mm |

Habka Dahaarka: Buufinta budada Electrostatic, Rinjiyeynta, Kulul-Dip-Galvanizing |

|

|

Dhexroorka Wareegga:48-219mm |

Codsiga: Miinada dhuxusha, warshada sibidhka, burburinta, warshada korontada, warshada birta, birta, dhagaxa, daabacaadda, warshadaha dib u warshadaynta iyo qalabka kale ee gudbinta |

|

|

Dhexroorka Faaska: 17-60mm |

Kahor iyo Adeegga Kadib: Taageero online ah, Taageerada farsamada ee fiidiyowga |

|

|

Astaanta Dhalashada: HRB, ZWZ, LYC, SKF, FAG, NSK |

||

Alaabta Halbeegyada

Alaabta Halbeegyada

|

Shaxda Halbeegga Weyn ee Gaadhiga suunka Idler |

||||

|

Dhexroorka caadiga ah |

Dhererka dhererka (mm) |

Nooca Dhalmada (min-max) |

Dhumucda gidaarka ee Roller-ka (mm) |

|

|

mm |

inji |

|||

|

63.5 |

2 1/2 |

150-3500 |

6204 |

2.0-3.75 |

|

76 |

3 |

150-3500 |

6204 205 |

3.0-4.0 |

|

89 |

3 1/3 |

150-3500 |

6204 205 |

3.0-4.0 |

|

102 |

4 |

150-3500 |

6204 205 305 |

3.0-4.0 |

|

108 |

4 1/4 |

150-3500 |

6204 205 305 306 |

3.0-4.0 |

|

114 |

4 1/2 |

150-3500 |

6205 206 305 306 |

3.0-4.5 |

|

127 |

5 |

150-3500 |

6204 205 305 306 |

3.0-4.5 |

|

133 |

5 1/4 |

150-3500 |

6205 206 207 305 306 |

3.5-4.5 |

|

140 |

5 1/2 |

150-3500 |

6205 206 207 305 306 |

3.5-4.5 |

|

152 |

6 |

150-3500 |

6205 206 207 305 306 307 308 |

3.5-4.5 |

|

159 |

6 1/4 |

150-3500 |

6205 206 207 305 306 307 308 |

3.0-4.5 |

|

165 |

6 1/2 |

150-3500 |

6207 305 306 307 308 |

3.5-6.0 |

|

177.8 |

7 |

150-3500 |

6207 306 307308 309 |

3.5-6.0 |

|

190.7 |

7 1/2 |

150-3500 |

6207 306 307308 309 |

4.0-6.0 |

|

194 |

7 5/8 |

150-3500 |

6207 307 308 309 310 |

4.0-6.0 |

|

219 |

8 5/8 |

150-3500 |

6308 309 310 |

4.0-6.0 |

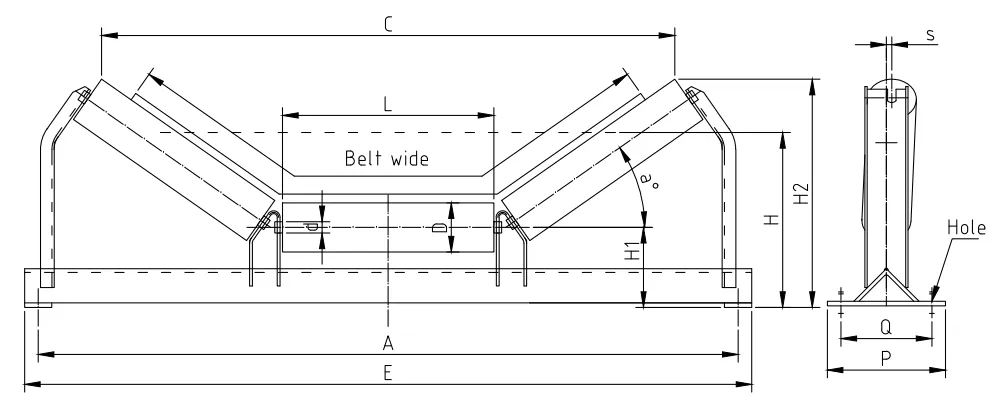

Diagrammatic Drawings and Parameters for Belt Conveyor Idler:

|

Balaadhka suunka (mm) |

D |

L |

D ama Nooca Dhalmada |

A |

E |

C |

H |

H1 |

H2 |

P |

Q |

S |

a° |

Dhererka godka dhexroorka |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Waxaa laga yaabaa inaad bixiso nambarka sawirka alaabta ama cabbirada cabbirka sare, habka ugu fiican ayaa ah inaad keento sawirka alaabta. |

||||||||||||||