Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

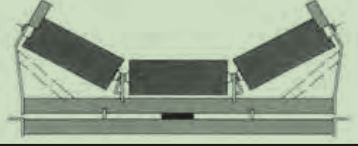

Zulu Tail Pulley Solutions for Efficient Conveyor Systems

Tail Pulley A Vital Component in Conveyor Systems

In the world of material handling and transportation, conveyor systems play a pivotal role in ensuring efficient and smooth operations. Among the various components that make up these systems, the tail pulley is an essential element often overlooked yet crucial in maintaining the overall functionality and performance of the conveyor belt.

The tail pulley is typically located at the end of a conveyor system and serves multiple purposes. It acts as a directional guide for the conveyor belt, ensuring proper alignment and reducing the risk of belt misalignment. When a conveyor system is in operation, the movement of the belt creates tension that needs to be correctly managed. The tail pulley helps in this regard by providing the necessary support to maintain the tension of the belt, which is vital for its effective operation. Proper tension ensures that the belt does not slip off the pulleys or suffer from excessive wear, which can lead to costly downtimes and repairs.

Moreover, the tail pulley is equipped with a drum where the conveyor belt wraps around. This design allows the pulley to drive the belt as it rotates, facilitating the transportation of materials from one point to another. Depending on the specific application and the type of materials being conveyed, tail pulleys can come in various sizes and designs. They may be fabricated using different materials, including steel, rubber, or plastic, each selected based on the environmental conditions and the nature of the materials being handled. For instance, a tail pulley used in a high-temperature environment might need to be made from heat-resistant materials to ensure durability and longevity.

tail pulley

An important aspect of the tail pulley is its end user maintenance and care. Regular inspection and maintenance are crucial to prevent potential failures that could disrupt operations. Maintenance tasks might include checking for wear and tear, ensuring proper alignment, and lubricating bearings to minimize friction. Neglecting these tasks can lead to serious issues, including belt slippage, which not only affects productivity but can also pose safety risks in the workplace.

Additionally, advancements in technology have introduced various innovations in tail pulley design and functionality. For example, tail pulleys with built-in sensors can monitor tension levels and provide real-time data to operators, helping them to proactively manage and maintain their conveyor systems. This technological integration has made it easier to optimize performance and reduce the risk of unexpected downtimes, leading to more efficient processes.

In conclusion, the tail pulley, while often underestimated, is a key component in the smooth operation of conveyor systems. It not only aids in belt alignment and tension management but also directly influences the overall efficiency and reliability of material handling operations. By understanding the importance of the tail pulley and committing to regular maintenance, businesses can enhance the performance of their conveyor systems, ensuring seamless operations and minimizing costly disruptions. As industries continue to evolve, the role of the tail pulley will remain fundamental in driving productivity and efficiency in material handling processes.

-

Wing Pulley Conveyor for Conveyor Belt MaintenanceNewsJun.16,2025

-

Self Cleaning Spiral Idler for Conveyor DesignNewsJun.16,2025

-

Pulley Lagging for Conveyor Belt AlignmentNewsJun.16,2025

-

Impact Idlers Used in Belt Conveyor for PerformanceNewsJun.16,2025

-

Ceramic Lagging Conveyor Pulley for Conveyor Belt SystemsNewsJun.16,2025

-

Belt Conveyor Idler for Heavy-Duty ApplicationsNewsJun.16,2025