Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu mining conveyor parts

Understanding Mining Conveyor Parts A Comprehensive Overview

In the mining industry, efficiency and safety are paramount, making conveyor systems vital components in the transportation of materials. These systems are designed to handle the arduous task of moving heavy loads over long distances in often challenging environments. Understanding the intricate parts of mining conveyors is essential for optimizing their performance and prolonging their operational life.

1. Key Components of Mining Conveyors

Mining conveyors consist of several key parts, each contributing to the overall functionality

- Belt The conveyor belt is the most prominent component. Made from durable materials such as rubber, fabric, or metal, it carries the mined materials. The choice of belt type depends on factors like the material being transported, distance, and the environment in which the conveyor operates.

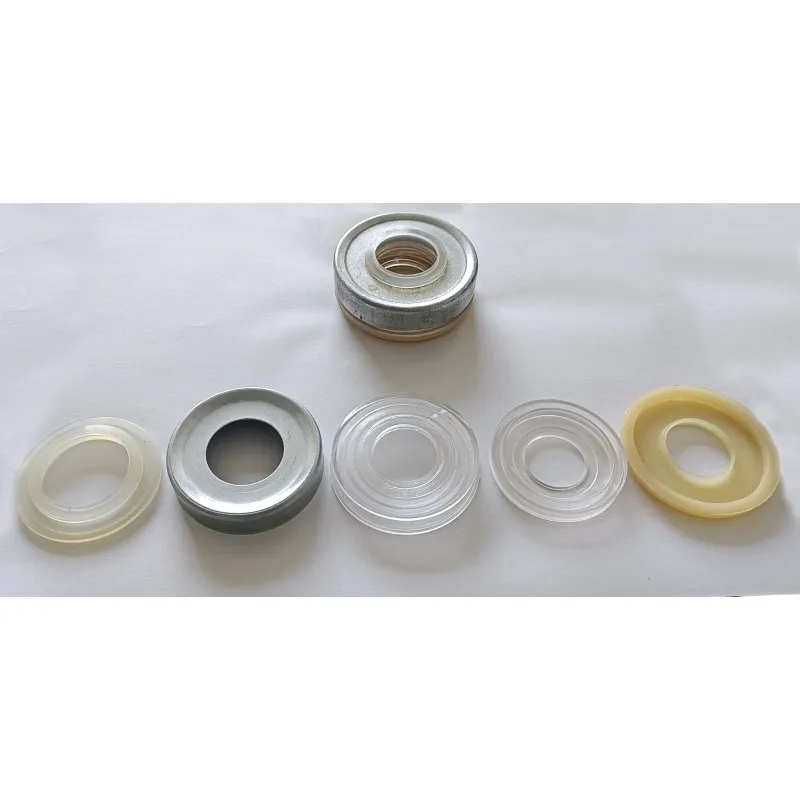

- Idlers These are the rollers that support the belt and keep it in position. Idlers reduce friction as the belt moves, allowing for smoother operation. They come in various designs, such as trough idlers and return idlers, depending on the load and application.

- Pulleys Located at both ends of the conveyor system, pulleys are critical for belt movement. The drive pulley initiates movement, while the take-up pulley maintains belt tension. Properly maintained pulleys ensure efficient operation and prevent slippage.

- Frame The frame is the structural backbone of the conveyor system, supporting all components. It is typically constructed from steel to withstand heavy loads and harsh mining environments. A sturdy frame is crucial for the longevity and reliability of the conveyor system.

- Drive System This includes the motor and gear mechanism that powers the conveyor. The drive system can be electric or hydraulic, and it is responsible for controlling the speed and direction of the conveyor belt. A well-maintained drive system is essential for optimal performance.

mining conveyor parts

Regular maintenance of conveyor parts is critical to avoid unexpected downtimes. Inspections should focus on key areas such as

- Belt Condition Regular checks for wear, tear, and damage to prevent breakdowns. - Idlers and Pulleys Ensuring they rotate smoothly and are free from debris. - Drive System Monitoring for signs of overheating or unusual vibrations which may indicate impending failure.

Investing in a preventive maintenance program can significantly enhance productivity, reduce operating costs, and minimize the risk of accidents.

3. Innovations in Conveyor Technology

With advances in technology, the mining industry is witnessing innovations in conveyor systems. Automation and smart technologies allow for real-time monitoring of conveyor performance, enabling predictive maintenance. Additionally, advancements in materials used for belts and other components lead to improved durability and resistance to harsh mining conditions.

Conclusion

Mining conveyor systems are an integral part of the mining process, relying on various components to function effectively. Understanding the different parts and their functions is essential for ensuring safety and efficiency in operations. Regular maintenance and adapting to technological advancements can significantly enhance the longevity and performance of these systems, ultimately contributing to the overall success of mining operations. As the industry evolves, staying informed about the latest developments in conveyor technology remains critical for those involved in mining logistics.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025