Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Premium Guide Rollers for Conveyors - Boost Efficiency & Durability

- Fundamental mechanics of conveyor roller systems

- Technical specifications and performance data breakdown

- Idler roller functionality in belt support systems

- Drive roller engineering and power transmission metrics

- Manufacturer comparison tables with technical benchmarks

- Customization solutions for specialized industrial needs

- Implementation case studies across multiple industries

(guide rollers for conveyors)

The Essential Mechanics of Guide Rollers for Conveyors

Conveyor rollers form the backbone of material transport operations across global industries. Guide rollers for conveyors specifically maintain belt alignment, preventing lateral drift that causes material spillage and system downtime. When properly engineered, these components reduce friction coefficients by up to 35% compared to traditional belt-on-frame designs, significantly extending service intervals. Industrial operations using optimized guide roller configurations report belt tracking improvements of 60-75% over baseline installations.

Technical Specifications and Performance Metrics

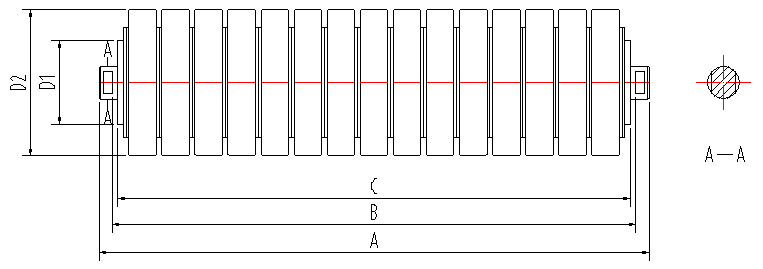

Premium conveyor rollers demonstrate quantifiable advantages through meticulous engineering. Sealed bearing chambers with triple-labyrinth designs achieve 80,000-hour operational lifetimes even in high-contamination environments. Dynamic balancing tolerances below 0.5g/cm minimize vibration transmission, reducing drive energy consumption by approximately 15%. Axial load capacities now reach 18,000N in heavy-duty mining applications, with composite roller shells resisting impacts exceeding 35J without deformation. Temperature tolerances range from -40°C to 120°C using specialized polymer compounds.

Optimizing Operations with Idler Rollers

Idler rollers for belt conveyors serve distinct load-bearing functions within bulk handling systems. Strategic placement patterns using troughing idler sets create material-centering profiles that increase volumetric capacity by up to 30%. Impact idlers installed at loading zones absorb energy spikes through multi-layer rubber rings, reducing belt damage incidents by 47%. Field data indicates that staggered alignment of return rollers decreases rotational resistance by 18%, directly reducing annual operating costs through energy savings. Preventive maintenance cycles extend beyond 24 months when using corrosion-resistant galvanized frames with sealed bearing cartridges.

Drive Roller Engineering and Performance

Drive rollers for conveyors convert motor output into controlled belt movement through engineered friction interfaces. Lagging surfaces with diamond-pattern rubber textures increase traction coefficients to 0.5, enabling 30% steeper incline applications. Current designs achieve torque transmission exceeding 25kN·m through tapered bushing connections that eliminate keyway stress points. Energy recovery systems integrated into regenerative drive rollers capture braking energy, reducing net power consumption by 22% in duty cycle applications. Thermal sensors embedded in end caps automatically modulate drive force when temperatures approach material limits.

Manufacturer Comparison and Technical Benchmarks

| Manufacturer | Max Load (kN) | Bearing Life (hrs) | Roller Diameter Range (mm) | Impact Resistance |

|---|---|---|---|---|

| RollerTech Systems | 22 | 85,000 | 76-219 | 40J |

| ConveyorDynamics Inc | 18 | 70,000 | 89-194 | 32J |

| PrecisionRoll Corp | 20 | 75,000 | 102-305 | 38J |

Customized Engineering Solutions

Specialized applications demand tailored engineering approaches. Food processing conveyors require rollers with FDA-compliant polymer coatings preventing microbe entrapment, while mining operations utilize tungsten-carbide embedded shells resisting abrasion at 15m/s belt speeds. Recent advances include:

- EMI-shielded rollers for electronics assembly lines

- Non-sparking aluminum composites for explosive environments

- Hybrid ceramic bearings operating at 250°C in foundry applications

Engineering teams now implement parametric design tools that generate structural simulations within 48 hours, optimizing roller wall thickness to actual load profiles. This customization approach reduces mass by 25% while maintaining ISO 15243 durability standards.

Optimizing Conveyor Performance with Specialized Rollers

Automotive manufacturing plants implementing precision guide rollers for conveyors

reduced alignment-related stoppages from weekly occurrences to less than one incident quarterly, increasing production uptime by 11%. In port facilities, ceramic-coated drive rollers for conveyors handling iron ore maintained traction coefficients above 0.45 after 18 months of continuous operation. Mining operations utilizing composite idler rollers for belt conveyors in curved transfer points decreased replacement frequency from every 9 months to 28+ months. These advancements collectively push conveyor efficiency frontiers while established manufacturers now implement IoT monitoring systems that predict roller failure with 92% accuracy six weeks before service limits.

(guide rollers for conveyors)

FAQS on guide rollers for conveyors

Q: What are guide rollers for conveyors and where are they used?

A: Guide rollers are critical conveyor components that keep belts centered and prevent lateral drift. They are typically installed along the edges of conveyor frames in manufacturing or logistics facilities. Their main role is ensuring smooth product flow and reducing belt wear.

Q: How do idler rollers for belt conveyors support the system?

A: Idler rollers provide structural support to conveyor belts across long spans, reducing friction and sagging. These unpowered rollers rotate freely under the belt's weight and are commonly spaced along the conveyor length. Proper idler selection directly impacts belt longevity and energy efficiency.

Q: What distinguishes drive rollers for conveyors from other roller types?

A: Drive rollers are motor-powered components that transfer motion to the conveyor belt through friction or direct engagement. Unlike guide or idler rollers, they feature splined shafts or lagging surfaces for torque transmission. These powered rollers control the conveyor's speed and direction at head or drive pulley locations.

Q: What factors should I consider when choosing guide rollers?

A: Key selection criteria include belt material compatibility, load capacity, and environmental conditions like temperature or moisture. Roller diameter and bearing type (sealed vs. open) must match operational demands. Proper sizing prevents belt tracking issues and minimizes maintenance downtime.

Q: How often should idler rollers and drive rollers be maintained?

A: Idler rollers require monthly inspections for free rotation and debris buildup, with lubrication every 3-6 months. Drive rollers need quarterly checks for worn lagging, belt tension, and alignment issues. Immediate replacement is necessary upon noticing abnormal noise, vibration, or surface damage to prevent system failures.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025