Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Exploring the Benefits and Applications of Rubber Lagging on Conveyor Pulley Systems for Enhanced Performance

Rubber Lagging for Conveyor Pulleys Enhancing Performance and Durability

Conveyor systems are an integral part of modern material handling, facilitating the efficient transport of bulk materials across various industries, from mining to manufacturing. Central to the functionality of these systems are conveyor pulleys, which serve as crucial components that help drive and redirect the conveyor belt. To optimize the performance and longevity of these pulleys, rubber lagging is frequently employed. This article will explore the benefits of rubber lagging, its applications, and considerations for selection and maintenance.

What is Rubber Lagging?

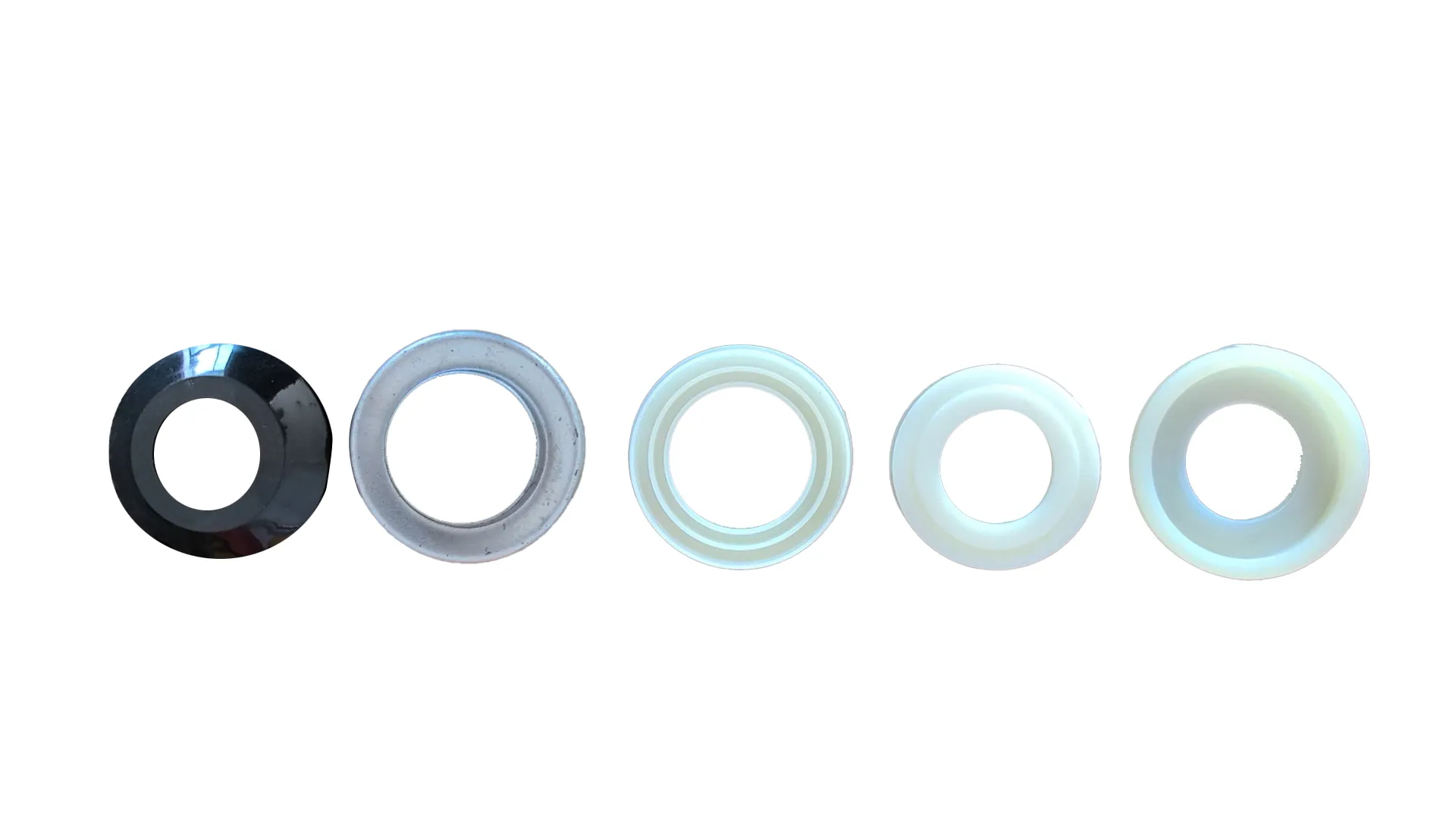

Rubber lagging refers to the application of rubber coatings on the surface of conveyor pulleys. This coating acts as a protective layer that enhances the pulley’s surface grip, thereby improving the friction between the pulley and the conveyor belt. Rubber lagging is particularly effective in reducing slippage and wear, which are common challenges faced in conveyor operations.

Benefits of Rubber Lagging

1. Increased Traction One of the primary benefits of rubber lagging is its ability to increase traction. The rubber surface provides a rough texture that helps grip the conveyor belt more effectively. This is particularly important in applications involving steep inclines or heavy loads where slip can result in significant material loss or damage.

2. Wear Resistance Rubber lagging helps to protect the underlying metal of the pulley from wear and tear due to abrasion. The durable nature of rubber shields the pulley from the harsh conditions often encountered in bulk material handling, extending the life of both the pulley and the conveyor system as a whole.

3. Noise and Vibration Reduction Rubber has natural dampening properties that can reduce noise and vibration associated with the operation of conveyor systems. This not only creates a quieter working environment but can also minimize wear on other components of the conveyor system.

4. Corrosion Protection In environments where pulleys are exposed to moisture or corrosive materials, rubber lagging can provide an added layer of protection against corrosion. This is essential for maintaining the structural integrity and performance of the pulley over time.

5. Customization Rubber lagging can be customized in terms of thickness, texture, and rubber composition, allowing for tailored solutions to meet the specific needs of different applications. This versatility makes it suitable for various industries including mining, agriculture, and recycling.

rubber lagging for conveyor pulley

Applications

Rubber lagging is typically used in a range of conveyor systems, particularly in heavy-duty applications where the risk of slippage and wear is higher. Common sectors employing rubber lagging include

- Mining and Aggregates In these industries, robust and reliable conveyor systems are necessary for transporting heavy loads over long distances. Rubber lagging reduces the risk of slippage, making it an essential addition to conveyor pulleys.

- Food Processing In food processing applications, hygienic standards must be maintained. Special grades of rubber lagging are available that are compliant with food safety regulations.

- Quarrying and Cement Production The harsh environments in these sectors demand materials that can withstand extreme conditions. Rubber lagging provides durability and protection against abrasives.

Considerations for Selection and Maintenance

When selecting rubber lagging, several factors should be considered, including the type of material being transported, load capacity, and environmental conditions. Additionally, regular maintenance of the rubber lagging is crucial to ensure its longevity. This involves inspecting the lagging for signs of wear and tear, such as cracking or peeling, and replacing it when necessary.

Conclusion

In conclusion, rubber lagging is an essential enhancement for conveyor pulleys that significantly improves their performance and lifespan. By providing increased traction, wear resistance, and protection against environmental factors, rubber lagging plays a vital role in ensuring the efficient operation of conveyor systems across various industries. Investing in quality rubber lagging not only enhances productivity but also contributes to the overall reliability of the material handling process.

-

Wing Pulley Conveyor for Conveyor Belt MaintenanceNewsJun.16,2025

-

Self Cleaning Spiral Idler for Conveyor DesignNewsJun.16,2025

-

Pulley Lagging for Conveyor Belt AlignmentNewsJun.16,2025

-

Impact Idlers Used in Belt Conveyor for PerformanceNewsJun.16,2025

-

Ceramic Lagging Conveyor Pulley for Conveyor Belt SystemsNewsJun.16,2025

-

Belt Conveyor Idler for Heavy-Duty ApplicationsNewsJun.16,2025