Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu ਫਰ. . 15, 2025 03:19

Back to list

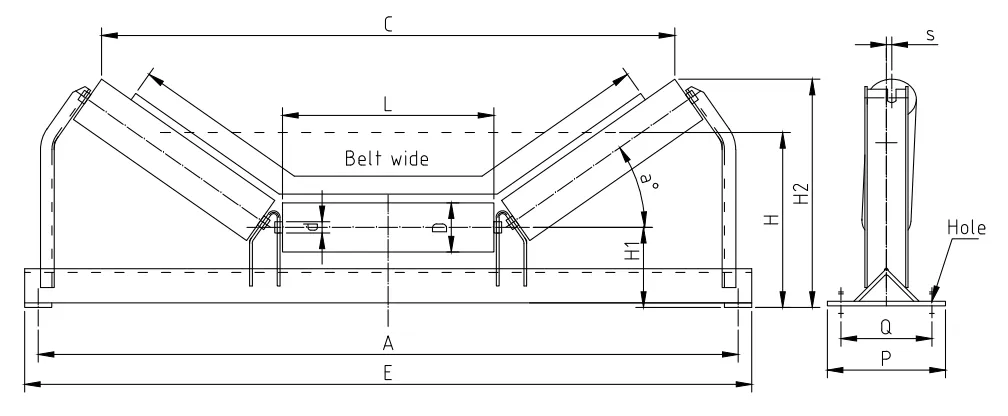

conveyor idler

The world of conveyor components is a complex landscape, characterized by a wide array of products, materials, and customization options tailored to meet the specific needs of various industries. When navigating this intricate domain, having a robust understanding and first-hand experience with these components is invaluable. This comprehensive guide aims to delve into the realm of conveyor components, from essential types to high-quality materials and modern innovations that optimize efficiency and reliability in production processes.

A significant trend in modern conveyor components is the shift toward advanced technologies and materials aimed at improving operational efficiency and reducing downtime. For example, the integration of smart sensors allows real-time monitoring of conveyor performance, detecting issues before they escalate into costly downtime. These sensors can track belt speed, pulley tension, and roller alignment, essential for preventive maintenance strategies. Another innovation is the development of conveyor components designed for easy assembly and disassembly, facilitating quick maintenance without extensive downtime. For industries where speed and efficiency are paramount, these modular systems provide a competitive advantage by enabling swift changes and upgrades. When considering the purchase of conveyor components, partnering with reputable suppliers known for their expertise and reliability is crucial. Companies that have established their authority in manufacturing quality components often offer insights and recommendations based on extensive field research and customer feedback, ensuring that their products meet stringent industry standards. Moreover, trustworthiness in this industry is built on transparency and the provision of comprehensive product data, including performance metrics, material specifications, and maintenance guidelines. Suppliers that offer detailed product documentation and support are often viewed as leaders in the market. In conclusion, selecting the right conveyor components requires a blend of expertise and experience. By understanding the specific needs of your production environment and leveraging the latest innovations, businesses can optimize their material handling processes, leading to enhanced productivity and reduced costs. The knowledge and reliability of your conveyor component supplier are pivotal in achieving these objectives, making the selection of components a strategic decision that can significantly affect operational success.

A significant trend in modern conveyor components is the shift toward advanced technologies and materials aimed at improving operational efficiency and reducing downtime. For example, the integration of smart sensors allows real-time monitoring of conveyor performance, detecting issues before they escalate into costly downtime. These sensors can track belt speed, pulley tension, and roller alignment, essential for preventive maintenance strategies. Another innovation is the development of conveyor components designed for easy assembly and disassembly, facilitating quick maintenance without extensive downtime. For industries where speed and efficiency are paramount, these modular systems provide a competitive advantage by enabling swift changes and upgrades. When considering the purchase of conveyor components, partnering with reputable suppliers known for their expertise and reliability is crucial. Companies that have established their authority in manufacturing quality components often offer insights and recommendations based on extensive field research and customer feedback, ensuring that their products meet stringent industry standards. Moreover, trustworthiness in this industry is built on transparency and the provision of comprehensive product data, including performance metrics, material specifications, and maintenance guidelines. Suppliers that offer detailed product documentation and support are often viewed as leaders in the market. In conclusion, selecting the right conveyor components requires a blend of expertise and experience. By understanding the specific needs of your production environment and leveraging the latest innovations, businesses can optimize their material handling processes, leading to enhanced productivity and reduced costs. The knowledge and reliability of your conveyor component supplier are pivotal in achieving these objectives, making the selection of components a strategic decision that can significantly affect operational success.

Next:

Latest news

-

Wing Pulley Conveyor for Conveyor Belt MaintenanceNewsJun.16,2025

-

Self Cleaning Spiral Idler for Conveyor DesignNewsJun.16,2025

-

Pulley Lagging for Conveyor Belt AlignmentNewsJun.16,2025

-

Impact Idlers Used in Belt Conveyor for PerformanceNewsJun.16,2025

-

Ceramic Lagging Conveyor Pulley for Conveyor Belt SystemsNewsJun.16,2025

-

Belt Conveyor Idler for Heavy-Duty ApplicationsNewsJun.16,2025

OUR PRODUCTS