Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  Engels

Engels  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu The Difference Between Rubber Lagging Pulley and Polyurethane Pulley

In industrial applications, pulleys play a crucial role in the performance and longevity of conveyor systems. The choice between a rubber lagging pulley and a polyurethane pulley can significantly impact the efficiency, durability, and maintenance of your conveyor system. Each type of pulley has its own set of advantages depending on the specific environment and operational demands. Let’s explore the key differences and advantages of each pulley to help you determine which one is most suitable for your application.

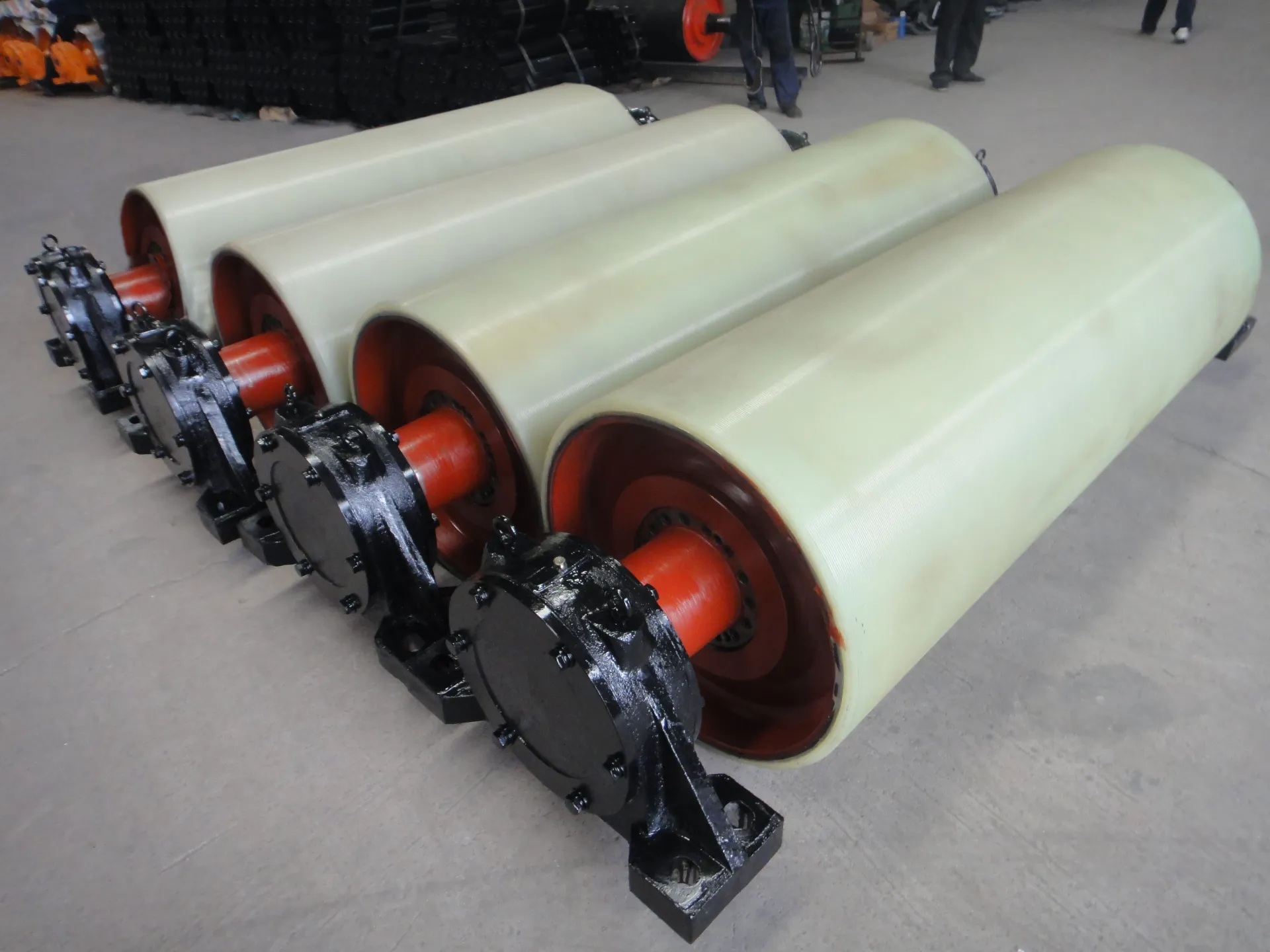

The Advantages of Rubber Lagging Pulley

A rubber lagging pulley is commonly used in environments where strong traction and grip are required. Rubber lagging increases the friction between the pulley and the conveyor belt, preventing slippage and reducing wear on the belt. This enhanced grip makes rubber lagging pulleys ideal for heavy-duty applications such as mining, aggregate handling, and other industries where materials are tough and abrasive.

One of the standout advantages of a rubber lagging pulley is its ability to absorb shock. This makes it suitable for environments with significant vibrations or material impacts, reducing the strain on the conveyor system and extending its lifespan. Additionally, rubber lagging offers better resistance to water and moisture, making it a reliable choice for outdoor applications or damp environments.

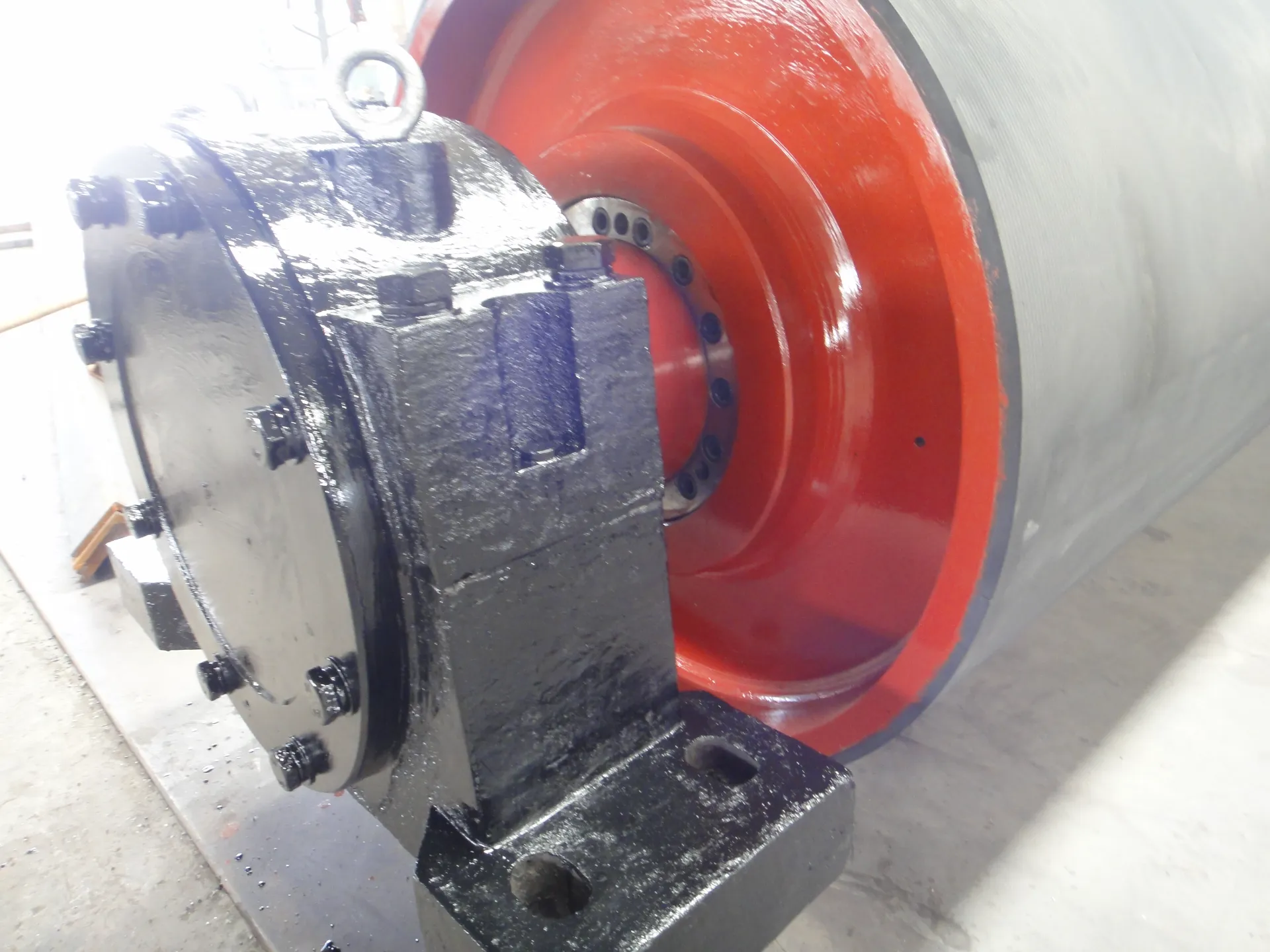

What is Suitable for Polyurethane Pulley

Polyurethane pulleys offer excellent resistance to chemicals, oils, and solvents, making them the preferred choice in industries such as food processing, chemical handling, and pharmaceuticals. Polyurethane is known for its strength and resilience, providing a high level of durability while maintaining flexibility. A polyurethane pulley is highly resistant to wear and abrasion, ensuring that it performs well in applications where the pulley will be in constant contact with the belt.

Unlike rubber, polyurethane is less likely to degrade over time when exposed to harsh substances, making it a long-lasting option in chemically demanding environments. Furthermore, polyurethane pulleys generate less heat during operation, reducing the risk of thermal degradation of the conveyor belt and pulley system.

Rubber Lagging Pulley vs Polyurethane Pulley: Which One is More Durable?

When comparing the durability of a rubber lagging pulley vs a polyurethane pulley, the answer largely depends on the specific application. In general, polyurethane offers superior durability in terms of resistance to chemicals and abrasion. Its ability to maintain strength over long periods, even in challenging environments, gives polyurethane the edge in durability for certain industries.

However, in environments where high traction and shock absorption are crucial, such as in mining or heavy industrial operations, the rubber lagging pulley tends to be more durable. The rubber provides a strong grip and can withstand the heavy stress associated with constant material handling, making it more suitable for high-impact environments.

Both types of pulleys are highly durable in their respective applications, but the choice comes down to the specific needs of the conveyor system.

Rubber Lagging Pulley vs Polyurethane Pulley: What’s the Difference?

The primary difference between a rubber lagging pulley and a polyurethane pulley is the material composition and how each performs in various environments.

Rubber lagging pulley: Known for its superior grip and shock absorption, it’s best suited for industries requiring high traction and resistance to outdoor elements like moisture. It’s also better in applications with substantial physical impacts or vibrations.

Polyurethane pulley: This pulley excels in environments with chemical exposure, maintaining integrity in industries like food processing and pharmaceuticals. It is also more resistant to heat and abrasion, making it ideal for high-speed operations where wear resistance is crucial.

Both rubber lagging pulleys and polyurethane pulleys offer distinct advantages depending on the operational environment. It’s important to carefully assess the specific requirements of your conveyor system to choose the pulley material that will optimize performance and longevity.

In conclusion, both rubber lagging pulleys and polyurethane pulleys provide significant advantages, but their suitability depends on the application. If you need high traction, shock absorption, and outdoor durability, the rubber lagging pulley is likely your best option. However, if chemical resistance, abrasion resistance, and long-term durability in harsh environments are priorities, the polyurethane pulley would be more appropriate. Understanding the differences between these two types of pulleys will ensure that your conveyor system operates efficiently and effectively, reducing downtime and maintenance costs.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNieuwsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNieuwsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNieuwsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNieuwsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNieuwsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNieuwsJul.22,2025