Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu ഫെബ്രു . 16, 2025 16:38

Back to list

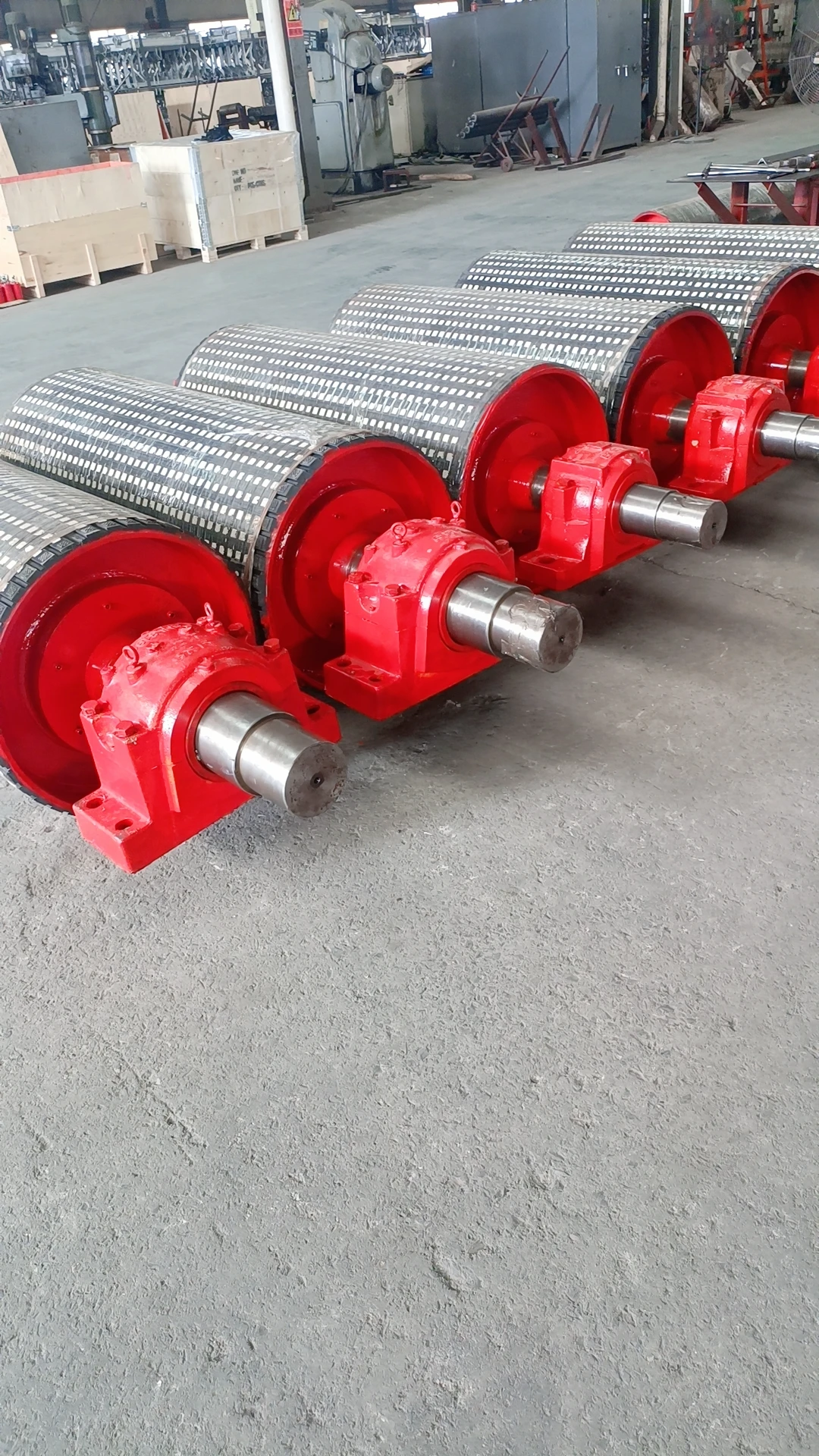

rubber disc return idlers

Rubber disc return idlers are revolutionizing the way industries handle bulk material transportation, offering unparalleled efficiency and durability. As the hidden hero in conveyor systems, these components are engineered to deliver high performance in demanding environments, ensuring prolonged equipment life and reduced maintenance costs.

When assessing the cost-benefit aspect of implementing rubber disc return idlers, the reduced energy consumption is evident. Their lightweight design requires less rotational torque to operate compared to heavier steel components, translating to energy savings and lower operating costs over time. Additionally, the longevity of rubber disc idlers decreases the frequency of replacements, contributing to a lower total cost of ownership over the lifecycle of the conveyor system. The technical prowess of these idlers does not just rest on material design, but also on their role in enhancing material flow efficiency. By maintaining a clean belt path and minimizing drag, they optimize belt tracking, effectively reducing the risk of costly misalignments and potential operational halts. This efficiency is critical in operations requiring continuous flow, making industries' logistics smoother and more predictable. Rubber disc return idlers also meet stringent environmental and safety standards. Given the reduction in noise and potential risks from belt misalignment, they contribute to safer work environments. In an era where sustainability and worker safety are paramount, investing in components that address these concerns is not just a regulatory compliance measure, but a corporate responsibility. In choosing rubber disc return idlers, companies are not only future-proofing their operations against wear and environmental challenges but are also embracing a component that speaks to economic sensibility. The synergy of durability, efficiency, and operational cost savings makes rubber disc return idlers an indispensable asset to any industry reliant on bulk material conveyance. By focusing on superior design and material integration, rubber disc return idlers are setting a new standard in conveyor system components, ensuring that industries remain competitive in an ever-demanding business landscape. Investing in this innovative solution reaffirms a commitment to operational excellence and sustainable industrial growth.

When assessing the cost-benefit aspect of implementing rubber disc return idlers, the reduced energy consumption is evident. Their lightweight design requires less rotational torque to operate compared to heavier steel components, translating to energy savings and lower operating costs over time. Additionally, the longevity of rubber disc idlers decreases the frequency of replacements, contributing to a lower total cost of ownership over the lifecycle of the conveyor system. The technical prowess of these idlers does not just rest on material design, but also on their role in enhancing material flow efficiency. By maintaining a clean belt path and minimizing drag, they optimize belt tracking, effectively reducing the risk of costly misalignments and potential operational halts. This efficiency is critical in operations requiring continuous flow, making industries' logistics smoother and more predictable. Rubber disc return idlers also meet stringent environmental and safety standards. Given the reduction in noise and potential risks from belt misalignment, they contribute to safer work environments. In an era where sustainability and worker safety are paramount, investing in components that address these concerns is not just a regulatory compliance measure, but a corporate responsibility. In choosing rubber disc return idlers, companies are not only future-proofing their operations against wear and environmental challenges but are also embracing a component that speaks to economic sensibility. The synergy of durability, efficiency, and operational cost savings makes rubber disc return idlers an indispensable asset to any industry reliant on bulk material conveyance. By focusing on superior design and material integration, rubber disc return idlers are setting a new standard in conveyor system components, ensuring that industries remain competitive in an ever-demanding business landscape. Investing in this innovative solution reaffirms a commitment to operational excellence and sustainable industrial growth.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS