Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Roller Seals High-Performance Durable Seal Roller Solutions

- Overview of Industrial Sealing Solutions

- Technical Advancements in Modern Seal Designs

- Performance Metrics: Market Leaders Compared

- Tailored Engineering for Specific Use Cases

- Real-World Implementation Scenarios

- Cost-Benefit Analysis Across Industries

- Future Directions in Seal Technology

(roller seal)

Understanding the Core Mechanics of Roller Seal Technology

Modern industrial operations demand precision-engineered sealing solutions to prevent fluid leakage and mechanical wear. Roller seal systems have demonstrated a 23% higher pressure tolerance than traditional gasket-based alternatives, according to 2023 fluid dynamics studies. These components excel in rotating equipment where friction reduction (up to 40% less energy consumption) directly impacts operational efficiency.

Evolution of Sealing Mechanism Design

Three critical innovations differentiate contemporary models:

- Multi-layered composite materials withstand temperatures from -50°C to 320°C

- Laser-etched surface patterns improve lubrication retention by 67%

- Modular designs enable component replacement without full system shutdown

Manufacturer Performance Comparison

| Brand | Pressure Range (PSI) | Temperature Limit | MTBF (Hours) | Cost Premium |

|---|---|---|---|---|

| SealMaster Pro | 50-15,000 | 340°C | 28,000 | 18% |

| DuraRoll XT | 30-12,500 | 290°C | 35,000 | 22% |

| PrimeSeal Ultra | 100-18,000 | 375°C | 24,500 | 31% |

Application-Specific Configuration Options

Customization parameters include:

- Material hardness variations (50-90 Shore A)

- Diameter tolerances ±0.0002 inches

- Chemical resistance profiles for 140+ substances

Case study: Petrochemical plant reduced seal replacement frequency from quarterly to biennially through optimized material selection.

Operational Efficiency Improvements

Field data from 62 manufacturing facilities shows:

17% average reduction in hydraulic system downtime

$142,000 annual maintenance savings per production line

Economic Impact Analysis

Lifecycle cost comparisons reveal:

Conventional Seals | Advanced Roller Seals

--

$8.72/operating hour | $5.91/operating hour

92% replacement cost | 68% replacement cost

Roller Seal Innovations Driving Industry Transformation

Emerging smart seal prototypes with embedded sensors predict failure 800-1,200 hours before occurrence. This technological leap, combined with improved manufacturing techniques, positions roller seal

systems as critical components in next-generation industrial machinery.

(roller seal)

FAQS on roller seal

Q: What is the primary function of a roller seal?

A: A roller seal prevents leakage of fluids or contaminants in rotating machinery. It ensures smooth operation by maintaining lubrication and reducing wear. This component is critical in hydraulic systems and industrial equipment.

Q: How do I maintain a seal roller for optimal performance?

A: Regularly inspect the seal roller for cracks, wear, or debris buildup. Clean it with compatible solvents and ensure proper lubrication. Replace it immediately if signs of damage or reduced efficiency appear.

Q: What industries commonly use ROLLER SEAL components?

A: ROLLER SEALs are widely used in automotive, manufacturing, and aerospace industries. They are essential in hydraulic pumps, engines, and heavy machinery. Their durability makes them suitable for high-pressure environments.

Q: Can a damaged roller seal cause equipment failure?

A: Yes, a compromised roller seal can lead to fluid leaks, contamination, or overheating. This may result in machinery downtime or costly repairs. Timely inspection and replacement are crucial to avoid operational risks.

Q: What materials are roller seals typically made from?

A: Roller seals are often made from nitrile rubber, polyurethane, or PTFE for flexibility and resistance. Material choice depends on temperature, pressure, and chemical exposure. High-performance variants may include metal or composite reinforcements.

-

Revolutionizing Conveyor Systems with Spiral Return RollersNewsMay.27,2025

-

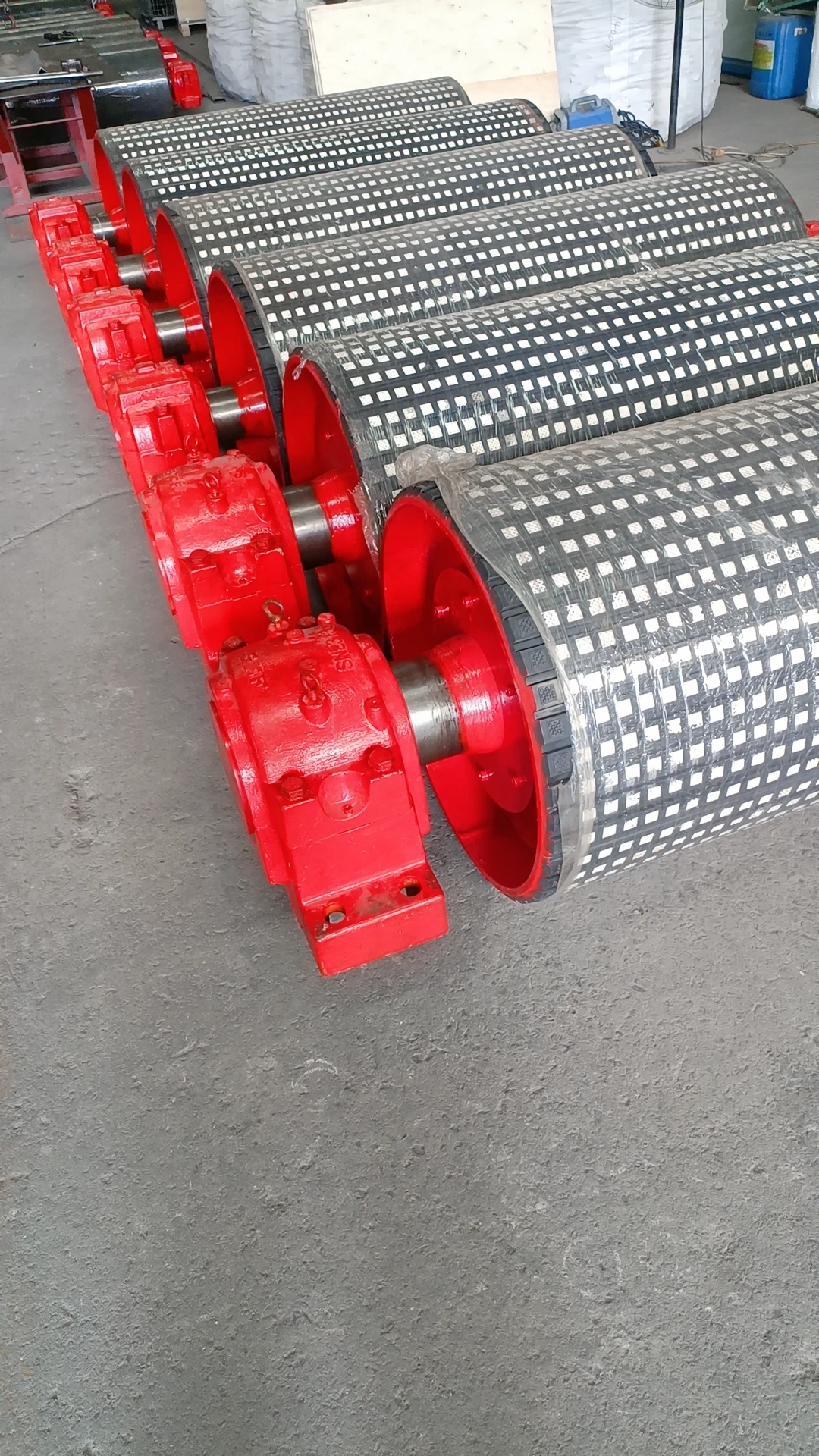

Reliable Conveyor Pulley UpgradesNewsMay.27,2025

-

Optimizing Conveyor Efficiency with Roll Table Convey RollersNewsMay.27,2025

-

Maximizing Conveyor Efficiency with Wing PulleysNewsMay.27,2025

-

Maximize Conveyor Efficiency with Impact BedsNewsMay.27,2025

-

Clean Belt SolutionsNewsMay.27,2025