Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Јан . 14, 2025 14:06

Back to list

pulley lagging types

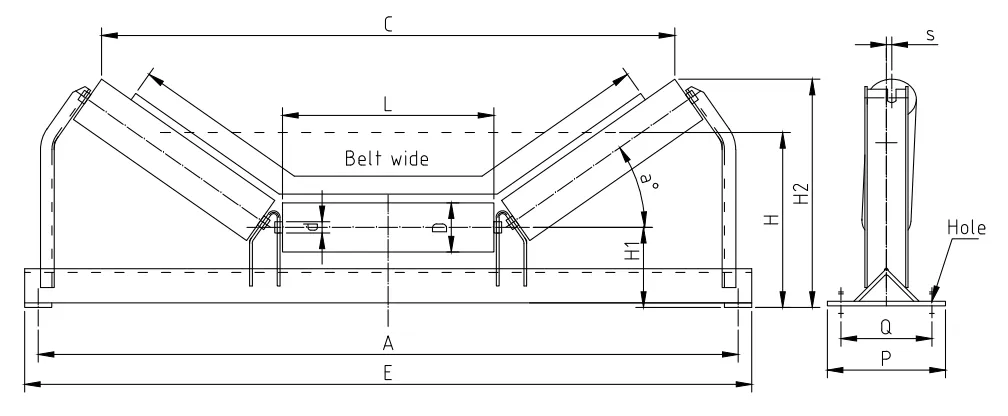

Pulley lagging is an essential component in conveyor systems, playing a critical role in enhancing the performance and longevity of the conveyor belt. Understanding the different types of pulley lagging is crucial for choosing the right materials that will ensure optimal functionality and efficiency. This guide explores the various types of pulley lagging, emphasizing their unique features, benefits, and applications to assist you in making informed decisions.

Chevron Lagging Known for its characteristic V-shaped pattern, chevron lagging is engineered for excellent resistance to belt slippage and high friction conditions. This type of lagging offers superior grip in both dry and wet environments, making it suitable for a variety of industrial applications. The chevron design directs any loose materials to the pulley edges, maintaining a clean surface and promoting consistent belt operation. Choosing chevron lagging can significantly enhance operational efficiency, especially in challenging conditions. Plain Lagging Unlike textured lagging, plain lagging offers a smooth surface ideal for conveyor systems where belt slip is not a significant concern. It provides a uniform tension across the width of the belt, making it suitable for light and medium-duty applications. While it might lack the gripping power of other types, plain lagging is beneficial in scenarios where minimum resistance is required. Its streamlined surface also simplifies cleaning and maintenance operations. In conclusion, selecting the appropriate type of pulley lagging is vital for maximizing the effectiveness and lifespan of your conveyor system. Each lagging type possesses unique attributes tailored to specific operational contexts. Whether you require heightened grip, increased durability, or specialized performance under specific conditions, understanding these differences will ensure that your conveyor system operates at peak efficiency. Investing in the right pulley lagging solution not only improves productivity but also enhances the overall reliability of the material handling processes. Make an informed choice to elevate your conveyor system’s performance today.

Chevron Lagging Known for its characteristic V-shaped pattern, chevron lagging is engineered for excellent resistance to belt slippage and high friction conditions. This type of lagging offers superior grip in both dry and wet environments, making it suitable for a variety of industrial applications. The chevron design directs any loose materials to the pulley edges, maintaining a clean surface and promoting consistent belt operation. Choosing chevron lagging can significantly enhance operational efficiency, especially in challenging conditions. Plain Lagging Unlike textured lagging, plain lagging offers a smooth surface ideal for conveyor systems where belt slip is not a significant concern. It provides a uniform tension across the width of the belt, making it suitable for light and medium-duty applications. While it might lack the gripping power of other types, plain lagging is beneficial in scenarios where minimum resistance is required. Its streamlined surface also simplifies cleaning and maintenance operations. In conclusion, selecting the appropriate type of pulley lagging is vital for maximizing the effectiveness and lifespan of your conveyor system. Each lagging type possesses unique attributes tailored to specific operational contexts. Whether you require heightened grip, increased durability, or specialized performance under specific conditions, understanding these differences will ensure that your conveyor system operates at peak efficiency. Investing in the right pulley lagging solution not only improves productivity but also enhances the overall reliability of the material handling processes. Make an informed choice to elevate your conveyor system’s performance today.

Next:

Latest news

-

The Unrivaled Performance of Polyurethane Pulleys in Industrial ApplicationsNewsAug.25,2025

-

The Critical Role of Drum Lagging in Conveyor SystemsNewsAug.25,2025

-

Navigating Industrial Efficiency: The Critical Role of Conveyor PulleysNewsAug.25,2025

-

InIntroduction to Advanced Pulley Lagging SolutionsNewsAug.25,2025

-

Industry Trends in Pulley Lagging TechnologyNewsAug.25,2025

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

OUR PRODUCTS