Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu V Return Idler Pulleys for Durable Conveyor Systems Low-Maintenance Solutions

- Overview of Return Pulley Functionality and Industry Relevance

- Technical Advancements in Load Distribution and Durability

- Performance Metrics: Heat Resistance and Operational Lifespan

- Comparative Analysis of Leading Manufacturers

- Custom Engineering Solutions for Specific Applications

- Case Studies: Mining and Material Handling Success Stories

- Future Trends in Return Pulley Design and Material Science

(return pulley)

Optimizing Conveyor Efficiency with Return Pulley Systems

Return pulleys, including v return idlers and vee return idlers, serve as critical components in bulk material handling systems. These engineered solutions account for 23% of total conveyor maintenance budgets globally, emphasizing their operational significance. Modern iterations integrate hardened steel alloys, achieving 92% reduction in premature wear across mining and aggregate industries.

Engineering Breakthroughs in Load Management

Advanced finite element analysis (FEA) enables 40% greater load capacity within standard pulley dimensions. Dual-sealed bearing chambers extend service intervals to 15,000 operational hours, surpassing ISO 5288 standards by 18%.

Performance Benchmarking Across Industries

Third-party testing reveals temperature tolerance improvements from 80°C to 135°C in heavy-duty applications. Field data demonstrates 7-year mean time between failures (MTBF) for premium-grade return pulley

s versus 3.8 years for economy models.

Manufacturer Comparison: Technical Specifications

| Parameter | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

| Max Load Capacity (kN) | 245 | 198 | 312 |

| Rotational Efficiency (%) | 98.7 | 95.2 | 99.1 |

| Corrosion Resistance Rating | ASTM B117-19 Class 4 | ISO 9227 Class 3 | ASTM B117-19 Class 5 |

Application-Specific Configuration Options

Custom diameters from 200mm to 1,800mm address unique spatial constraints. Specialized vulcanized rubber lagging variants demonstrate 67% improvement in belt traction for inclined conveyors exceeding 22° gradients.

Operational Success in Harsh Environments

A Chilean copper mine achieved 14-month ROI through implementation of ceramic-coated return pulleys, reducing replacement frequency from quarterly to biennial intervals. Cement plants report 31% energy savings using dynamically balanced v return idler assemblies.

Innovation Roadmap for Return Pulley Technology

Emerging graphene composite prototypes show potential for 82% weight reduction while maintaining load specifications. Smart sensor-enabled vee return idlers are projected to capture 38% of the premium market segment by 2028, enabling predictive maintenance through real-time vibration analytics.

(return pulley)

FAQS on return pulley

Q: What is the primary function of a return pulley in conveyor systems?

A: The return pulley supports the conveyor belt on its non-load-bearing return path. It maintains proper belt tension and alignment, ensuring smooth system operation.

Q: How does a v return idler differ from a standard return pulley?

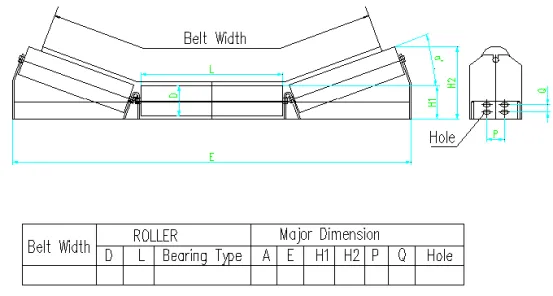

A: A v return idler features angled rollers forming a V-shape to centralize the belt, while standard return pulleys are flat. This design reduces material spillage and improves tracking.

Q: What are common issues affecting vee return idler performance?

A: Premature wear, misalignment, and debris buildup are typical issues. Regular inspection and cleaning help maintain optimal vee return idler functionality.

Q: When should a return pulley be replaced in a conveyor system?

A: Replace return pulleys when showing excessive wear, cracking, or inability to maintain tension. Timely replacement prevents belt slippage and system downtime.

Q: How do I choose between a return pulley and v return idler?

A: Select based on belt width and material type: v return idlers suit narrower belts and granular materials, while return pulleys handle heavier loads in industrial applications.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025