Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu ມ.ກ. . 28, 2025 06:10

Back to list

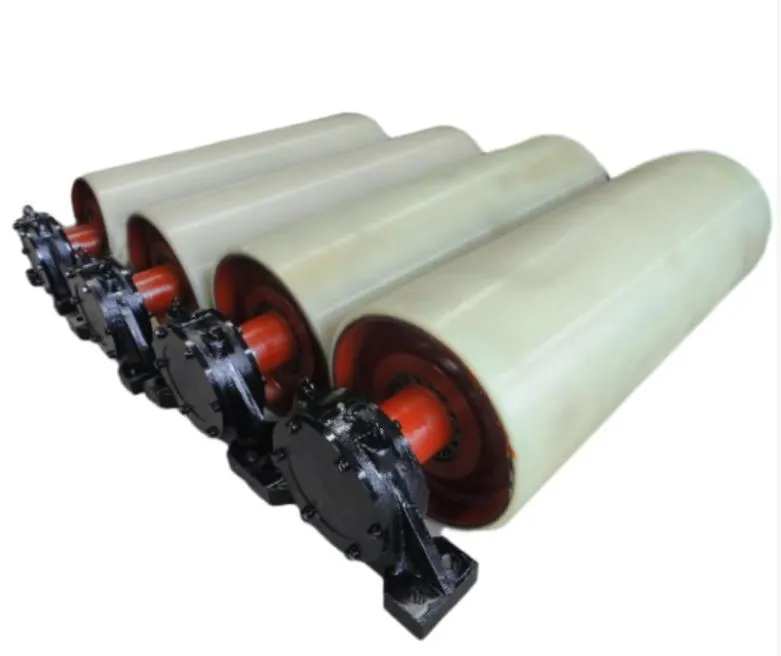

Return Idler Bracket

In the realm of industrial operations, conveyor belts stand as quintessential components that bolster efficiency, safety, and productivity. These mechanical movers provide an automated way to move goods in production and distribution settings, acting as an integral backbone in various industries. Understanding the parts and functions of conveyor belts is critical for businesses aiming to maintain smooth operations and optimized performance.

6. Belt Cleaner Maintaining belt cleanliness is crucial for preventing material buildup, which can cause blockages and reduce efficiency. Innovative belt scrapers or cleaners are introduced to keep the conveyor surface clean, facilitating long-term operational effectiveness. 7. Take-Up Unit This component maintains appropriate tension on the belt, thereby ensuring smooth motion and preventing slippage or slack. Take-up units, often adjusted through springs or screws, are crucial in maintaining alignment and tension integrity, particularly across varying load conditions. Balancing these components harmoniously in a conveyor belt system demands experience with the specific nuances of industrial operations. Knowledgeable engineers or experts examine these parts for their condition and functionality, ensuring a solid and trusted operational regime. Expertise in conveyor systems extends to understanding the nuances of various belt types and components, each suited for different industrial needs. Automation advances bring about smart conveyors equipped with sensors and AI for real-time monitoring, predictive maintenance, and operational analytics, keeping businesses at the cutting edge of productivity and efficiency. Authoritative and trusted knowledge in the conveyor belt domain is reinforced through continuous professional development and staying updated on technological advancements. Industry leaders must invest in quality equipment and consistently train their workforce to minimize operational downtimes and maximize efficiency. By comprehending the intricate details of conveyor belt parts and functions, businesses can leverage this machinery to propel productivity and achieve substantial operational excellence. Proper maintenance and the strategic choice of components tuned to the industry’s needs result in not only optimized processes but also amplified profitability.

6. Belt Cleaner Maintaining belt cleanliness is crucial for preventing material buildup, which can cause blockages and reduce efficiency. Innovative belt scrapers or cleaners are introduced to keep the conveyor surface clean, facilitating long-term operational effectiveness. 7. Take-Up Unit This component maintains appropriate tension on the belt, thereby ensuring smooth motion and preventing slippage or slack. Take-up units, often adjusted through springs or screws, are crucial in maintaining alignment and tension integrity, particularly across varying load conditions. Balancing these components harmoniously in a conveyor belt system demands experience with the specific nuances of industrial operations. Knowledgeable engineers or experts examine these parts for their condition and functionality, ensuring a solid and trusted operational regime. Expertise in conveyor systems extends to understanding the nuances of various belt types and components, each suited for different industrial needs. Automation advances bring about smart conveyors equipped with sensors and AI for real-time monitoring, predictive maintenance, and operational analytics, keeping businesses at the cutting edge of productivity and efficiency. Authoritative and trusted knowledge in the conveyor belt domain is reinforced through continuous professional development and staying updated on technological advancements. Industry leaders must invest in quality equipment and consistently train their workforce to minimize operational downtimes and maximize efficiency. By comprehending the intricate details of conveyor belt parts and functions, businesses can leverage this machinery to propel productivity and achieve substantial operational excellence. Proper maintenance and the strategic choice of components tuned to the industry’s needs result in not only optimized processes but also amplified profitability.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS