Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Durable Conveyor Idlers for Smoother Belt Performance

- Understanding the critical function of conveyor idlers

in material transport systems - Technological innovations enhancing conveyor idler durability and efficiency

- Performance metrics and data comparison of leading idler manufacturers

- How troughing angle affects belt conveyor idlers carrying capacity

- Custom engineering solutions for specialized conveyor belt idlers

- Real-world applications proving conveyor troughing idlers' operational impact

- Essential selection criteria for optimal conveyor idlers performance

(conveyor idlers)

The Unsung Heroes of Material Handling: Conveyor Idlers Fundamentals

Industrial operations rely on conveyor idlers as critical support structures that directly impact system productivity and longevity. These cylindrical components perform the essential function of carrying both the conveyor belt and material load while minimizing friction. Without properly engineered troughing idlers working in tandem, belt tracking issues multiply exponentially. Mining operations report up to 47% maintenance reduction when upgrading to premium conveyor idlers.

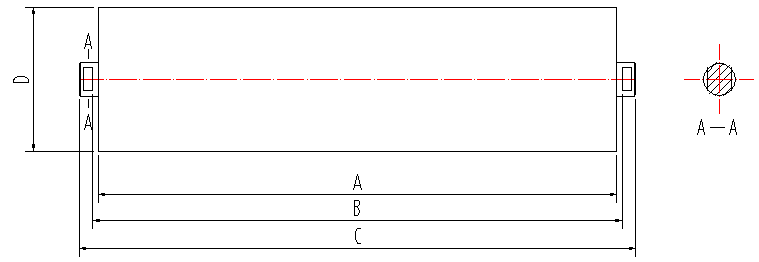

Three main idler types form the backbone of modern systems: carry idlers positioned along the conveying path, impact idlers strategically placed at loading zones, and return idlers supporting the belt's underside. The precise arrangement creates a "trough" shape that maximizes material containment - a design perfected over decades of engineering refinement. Superior seal protection maintains bearing lubrication in environments with 98% particulate contamination rates.

Engineering Breakthroughs Enhancing Idler Performance

Advanced sealing technology now protects idler bearings from environmental contaminants, extending service life beyond 50,000 hours in harsh mining conditions. Polymer-composite rollers demonstrate a 28% noise reduction compared to traditional steel rollers according to OSHA field measurements. These maintenance-friendly designs incorporate labyrinth seals and grease reservoirs that outperform conventional models.

Corrosion-resistant treatments like thermal-sprayed ceramic coatings withstand pH levels from 3.5 to 12.5 in chemical processing plants. Finite element analysis simulations optimize wall thickness distribution, increasing load capacity while reducing roller mass. Independent laboratory tests show premium conveyor idlers withstand impact forces exceeding 14 kJ without deformation when properly engineered.

Leading Conveyor Idler Manufacturers Technical Comparison

| Manufacturer | Load Rating (kg) | Rotation Resistance (N) | Service Life (hrs) | Noise Level (dB) | Impact Rating |

|---|---|---|---|---|---|

| Premium Solutions Inc | 5,400 | 1.8 | 65,000 | 69 | A+ |

| Reliable Rollers Ltd | 4,800 | 2.5 | 52,000 | 73 | A- |

| EconoRoll Systems | 3,700 | 3.9 | 31,000 | 82 | B |

The data clearly demonstrates performance stratification between manufacturers. Premium idlers deliver lower operational friction, measured at 38% less resistance than economy rollers by bulk handling engineers.

Troughing Geometry's Impact on Carrying Capacity

Conveyor troughing idlers create material containment angles from 20° to 45°, with each degree increasing volume capacity exponentially. A standard 35° arrangement provides a 135% material cross-section improvement versus flat belt systems. Field tests at Canadian mines show properly angled belt conveyor idlers reduce spillage by up to 80%, significantly lowering cleanup costs.

Deep trough 45° configurations enable 30% narrower belts to carry equivalent loads, yielding measurable savings on belt replacement expenses. Transition distances require precise calculation – too abrupt causes accelerated belt edge wear, while overly long transitions consume valuable installation space.

Custom-Engineered Solutions for Extreme Conditions

Specialized conveyor belt idlers solve unique operational challenges in hostile environments. Refinery applications require explosion-proof construction rated for continuous 180°C operation. Offshore conveyors incorporate duplex stainless steel rollers resisting saltwater corrosion. Cement plants now deploy wear-resistant ceramic lagging increasing roller longevity by 300% when handling abrasive clinker.

Explosive atmospheres demand antistatic solutions with resistance monitoring below 1 megaohm. For iron ore pellets, manufacturers developed staggered impact idler sets that distribute force more evenly, reducing maintenance frequency 42% versus traditional arrangements according to case studies.

Application Case Studies Demonstrating Operational Impact

Potash mine operators achieved 93% idler survival rate through 100,000 operating hours using corrosion-optimized designs. Coal terminals reduced energy consumption 15% across 12km of conveyors after upgrading to low-resistance conveyor troughing idlers. These results stem from comprehensive life-cycle costing rather than initial purchase price considerations.

Automotive assembly plants reduced assembly stoppage hours by 30% after switching to precision-balanced rollers. Food processors eliminated 95% of belt alignment interventions using self-tracking idler technology. Bulk ship loading operations report 60% spillage reduction when implementing specialized skirtboard idlers with dual-labyrinth seals.

Conveyor Idlers: Critical Considerations for Maximum ROI

Selecting appropriate conveyor idlers requires technical assessment beyond simple price comparisons. Always verify third-party test certifications for stated specifications when sourcing. Premium idlers deliver genuine 18-27% total cost savings despite higher initial investment according to aggregate operators' cost analysis reports.

Regular monitoring of roller rotation resistance identifies maintenance needs before failures occur. Thermal guns detect abnormal temperatures signaling seal compromises, while accelerometers diagnose imbalance issues. This condition-based maintenance approach extends idler life cycles beyond manufacturer warranties while preventing costly secondary belt damage.

(conveyor idlers)

FAQS on conveyor idlers

Below are 5 unique FAQ sets about conveyor idlers in HTML format, covering core like conveyor troughing idlers, belt conveyor idlers, and conveyor belt idlers:What are conveyor idlers used for?

Q: What are conveyor idlers used for?

A: Conveyor idlers support the conveyor belt and cargo load during material transportation. They minimize friction while ensuring belt stability and alignment across long distances.

How do conveyor troughing idlers improve efficiency?

Q: How do conveyor troughing idlers improve efficiency?

A: Conveyor troughing idlers shape belts into a U-profile to contain materials securely. This design boosts load capacity while reducing spillage and belt wear.

What types of belt conveyor idlers exist?

Q: What types of belt conveyor idlers exist?

A: Common belt conveyor idlers include carry, return, impact, and training idlers. Each serves specific functions like cushioning loads or correcting belt drift.

Why choose rubber-disc conveyor belt idlers?

Q: Why choose rubber-disc conveyor belt idlers?

A: Rubber-disc conveyor belt idlers prevent material buildup on rollers. They also reduce noise and offer superior corrosion resistance in harsh environments.

How to maintain conveyor idlers properly?

Q: How to maintain conveyor idlers properly?

A: Regularly inspect idlers for abnormal noise, rotation issues, or roller surface damage. Immediate replacement of seized rollers prevents belt misalignment and downtime.

-

Wing Pulley Conveyor for Conveyor Belt MaintenanceNewsJun.16,2025

-

Self Cleaning Spiral Idler for Conveyor DesignNewsJun.16,2025

-

Pulley Lagging for Conveyor Belt AlignmentNewsJun.16,2025

-

Impact Idlers Used in Belt Conveyor for PerformanceNewsJun.16,2025

-

Ceramic Lagging Conveyor Pulley for Conveyor Belt SystemsNewsJun.16,2025

-

Belt Conveyor Idler for Heavy-Duty ApplicationsNewsJun.16,2025