Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

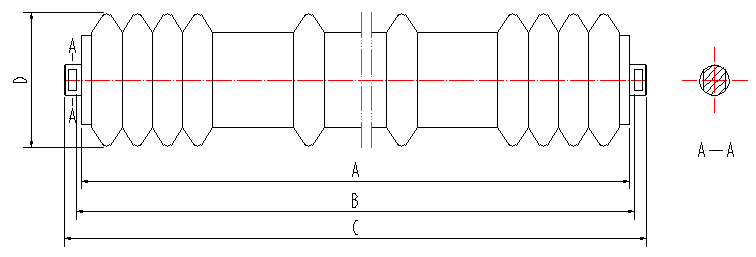

Zulu wing tail pulley

The Wing Tail Pulley An Essential Component in Aviation Technology

In the world of aviation, engineering innovations play a critical role in enhancing aircraft performance, safety, and efficiency. One such innovation is the wing tail pulley, a vital component that ensures the optimal functioning of an aircraft's control surfaces. This article delves into the significance, design, and functionality of the wing tail pulley, shedding light on its contribution to modern aeronautics.

Understanding the Wing Tail Pulley

A wing tail pulley is a mechanical device used in aircraft to connect the control surfaces, such as the elevators and rudders, to the cockpit controls. It acts as a crucial intermediary that ensures the pilot’s commands are effectively transmitted to the aircraft’s tail, allowing for precise maneuverability during flight. Typically made from high-strength materials, these pulleys must endure the rigorous demands of high-speed flight while maintaining reliability and accuracy.

Key Functions

The primary function of a wing tail pulley is to redirect the cables from the cockpit to the control surfaces located at the tail of the aircraft. When a pilot pulls or pushes the control stick, the movement is transferred through a series of pulleys and cables. This system enables the pilot to adjust the aircraft's attitude, impacting its pitch and yaw. Such maneuverability is essential for various flight operations, including climbing, descending, and turning.

Moreover, the wing tail pulley assists in maintaining the structural integrity of the control cable system. By minimizing friction and wear, these pulleys help ensure that the cables operate smoothly over time, reducing the risk of failure. This is particularly important for ensuring the safety of the aircraft, as any malfunction in the control systems can lead to catastrophic outcomes.

Design and Engineering Considerations

wing tail pulley

The design of wing tail pulleys is a testament to the advanced engineering that goes into aviation. Engineers must consider multiple factors, including weight, strength, and aerodynamics. Most wing tail pulleys are designed to be lightweight yet robust, allowing them to bear significant loads without adding excessive weight to the aircraft. The materials used, such as aluminum alloys or composite materials, are selected for their strength-to-weight ratio, ensuring durability without compromising performance.

Additionally, the pulley system must be designed with precision. Any misalignment can lead to inefficient control and potential failure. Therefore, engineers employ advanced computer-aided designs (CAD) and simulation tools to model the pulley system’s behavior under various flight conditions. This rigorous testing ensures that the final product meets all safety and performance standards.

The Future of Pulley Systems in Aviation

As technology advances, the future of wing tail pulleys is likely to see significant improvements. With the advent of automation and fly-by-wire systems, the traditional mechanical pulley systems may evolve. These systems replace mechanical linkages with electronic signals, reducing the need for physical pulleys. However, even in a more automated environment, the fundamental principles of reliability and precision will remain critical.

Emerging materials, such as advanced composites and smart materials, may also revolutionize the design of wing tail pulleys. These innovations could lead to even lighter, stronger, and more efficient components, enhancing overall aircraft performance and safety.

Conclusion

In conclusion, the wing tail pulley is a small yet essential component of modern aviation that plays a crucial role in ensuring effective control of aircraft. Its design and functionality reflect the intricate engineering that underpins flight technology. As the aviation industry continues to evolve, the wing tail pulley will remain a symbol of reliability and efficiency, contributing to the safety and performance of aircraft for years to come. Understanding its importance helps us appreciate the sophisticated mechanisms that allow pilots to navigate the skies with precision and confidence.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025