Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu v belt tensioner pulley

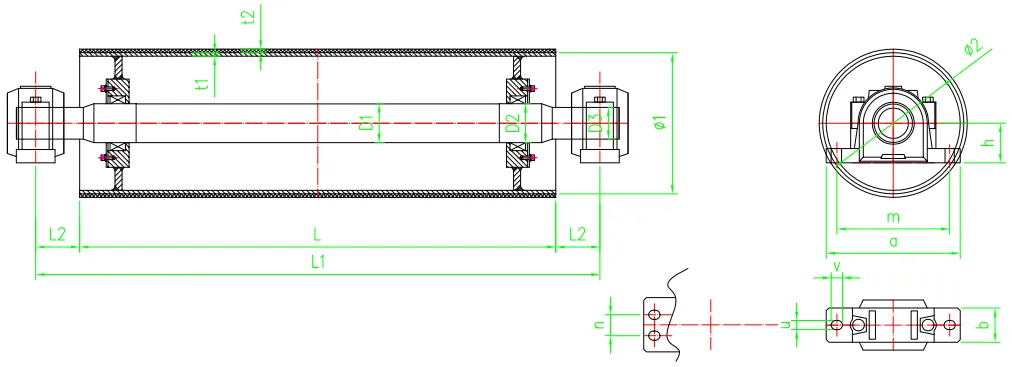

Understanding V-Belt Tensioner Pulleys

In the world of automotive engineering and machinery, the smooth operation of components is paramount. One crucial component that plays a significant role in this regard is the V-belt tensioner pulley. This device is essential for maintaining the proper tension on V-belts used in a variety of applications, including engines, alternators, air conditioning compressors, and more.

The primary function of a V-belt tensioner pulley is to ensure that the belt remains tight enough to prevent slipping while allowing for some flexibility during operation. The design of V-belts necessitates a certain level of tension to function efficiently; if the belt is too loose, it may slip, causing a loss of traction and ultimately leading to system failure. Conversely, if the belt is too tight, it may impose excessive strain on both the belt and the components it drives, potentially leading to premature wear or catastrophic failure.

Components of a V-Belt Tensioner Pulley

A typical V-belt tensioner pulley consists of several components the pulley itself, a spring mechanism, and often a dampening feature. The pulley is usually made from durable materials designed to withstand wear and resist deformation over time. The spring mechanism is responsible for adjusting the tension of the belt dynamically; as the belt stretches due to normal wear and tear, the spring compensates by exerting a constant force to keep the belt taut.

Additionally, some tensioners include hydraulic or pneumatic dampers to further cushion the movement and prevent shock loads from affecting the belt and connected components. This can be particularly important in high-performance applications where sudden changes in speed and torque can occur.

v belt tensioner pulley

Maintenance and Issues

Proper maintenance of V-belt tensioner pulleys is crucial to avoid costly repairs and downtime. As with any mechanical component, tensioners can wear out over time. Common signs of wear include squeaking or squealing noises, visible cracks or wear on the belt, and erratic behavior in the belt system, such as slipping or jumping.

Regular inspection and replacement of worn components can help prolong the life of the belt and improve the efficiency of the entire system. It is advisable to check the tensioner pulley whenever the V-belt is replaced or serviced to ensure optimal performance.

Conclusion

In summary, the V-belt tensioner pulley is a vital component in ensuring the longevity and reliability of belt-driven systems. By providing the necessary tension, it plays a critical role in maintaining the efficiency of various automotive and industrial applications. Understanding its function, components, and maintenance requirements can help users and technicians alike to make informed decisions, ultimately leading to better performance and reduced operational costs. Whether for a car engine or an industrial machine, the importance of a well-functioning V-belt tensioner pulley cannot be overstated.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025