Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu troughing rollers manufacturers

Understanding Troughing Rollers Key Components and Leading Manufacturers

Troughing rollers play a critical role in the design and operation of conveyor systems used in various industries, including mining, agriculture, and manufacturing. These rollers help to support and maintain the proper alignment of conveyor belts, ensuring efficient material handling and transporting operations. Understanding the significance of troughing rollers and identifying leading manufacturers in the industry can aid in better system design and enhancements in overall productivity.

What are Troughing Rollers?

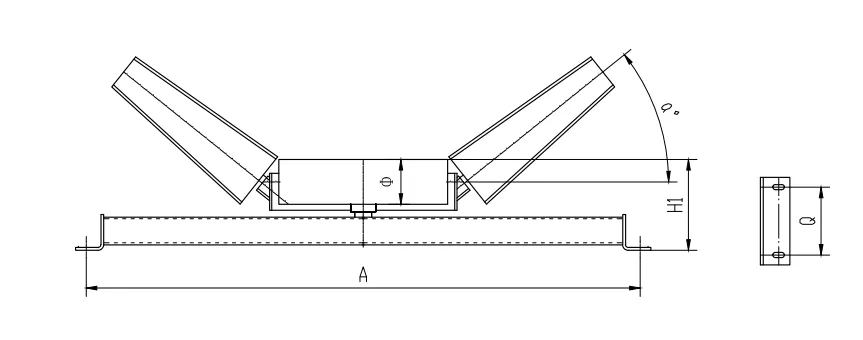

Troughing rollers are cylindrical components that are used to aid the movement of conveyor belts, particularly in applications where the transportation of bulk materials is involved. These rollers are designed to create a 'trough' shape in the conveyor belt, which serves two key purposes it allows for the containment of materials to prevent spillage and it provides better belt support over long distances. Typically, troughing rollers are installed at various angles, most commonly at 20, 35, or 45 degrees, depending on the specific requirement of the conveyor system.

The rollers are made from robust materials, often featuring a rubber or composite outer layer to ensure durability and resistance to wear and tear. The bearings used in troughing rollers are also engineered for high performance, often designed to reduce friction and extend the lifespan of the roller, thereby minimizing maintenance costs and downtimes.

Importance of Troughing Rollers

Troughing rollers contribute significantly to the efficiency and longevity of conveyor systems. The advantages they provide include

1. Material Containment By creating a trough shape, they help prevent spillage during the conveyance of bulk materials, minimizing loss and environmental hazards.

2. Increased Load Support Multiple troughing rollers can support larger loads without compromising the integrity of the belt or the system.

3. Reduced Wear on Belts Properly aligned and maintained troughing rollers reduce the friction between the belt and the conveyor, leading to lower wear rates and improved belt life.

troughing rollers manufacturers

5. Versatile Applications They are used in a multitude of industries, making them extremely versatile. Whether it is for moving coal, grains, or manufactured goods, troughing rollers can be adapted to meet various demands.

Leading Manufacturers of Troughing Rollers

With the growing demand for reliable conveyor systems, several manufacturers have emerged as leaders in the production of troughing rollers. When considering quality and performance, here are some notable manufacturers

1. Martin Engineering Known for innovative solutions, Martin Engineering offers a comprehensive range of troughing rollers designed for high performance and durability. Their products are widely used in various industries and come with extensive support services.

2. Dunlop Conveyor Belting With a strong reputation in the industry, Dunlop specializes in manufacturing high-quality conveyor belts and rollers. Their troughing rollers are designed to withstand heavy loads and extreme conditions, making them ideal for challenging environments.

3. Kinder Australia Kinder provides a diverse range of conveyor components, including an impressive variety of troughing rollers. They focus on delivering innovative solutions that enhance the efficiency and safety of conveyor systems.

4. SKE Conveyor SKE Conveyor is known for its extensive range of conveyor products, including customized troughing rollers for specific requirements. They emphasize engineering excellence and cater to various industrial applications.

5. Roller Manufacturing Companies There are numerous local and global roller manufacturers that specialize in producing customized troughing rollers to meet specific needs for different industries, ensuring that every client finds the right solution for their operations.

Conclusion

Troughing rollers are essential for the effective operation of conveyor systems across various industries. Their design and capabilities allow for enhanced material handling, increased system reliability, and reduced operational costs. By choosing quality troughing rollers from leading manufacturers, businesses can ensure optimal performance and efficiency in their material transportation systems. As industries continue to evolve and embrace new technologies, the demand for advanced conveyor solutions, including high-quality troughing rollers, will undoubtedly increase. Therefore, identifying and partnering with reputable manufacturers is crucial for sustained operational success.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025