Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Manufacturers of Troughing Idlers for Efficient Material Handling Solutions

Understanding Troughing Idlers The Backbone of Conveyor Systems

In the realm of material handling and conveyor systems, troughing idlers play a crucial role. These components are integral to the efficient transportation of bulk materials across various industries, such as mining, agriculture, and manufacturing. As practitioners and manufacturers increasingly focus on optimizing conveyor systems, understanding the significance and functionality of troughing idlers becomes essential.

What Are Troughing Idlers?

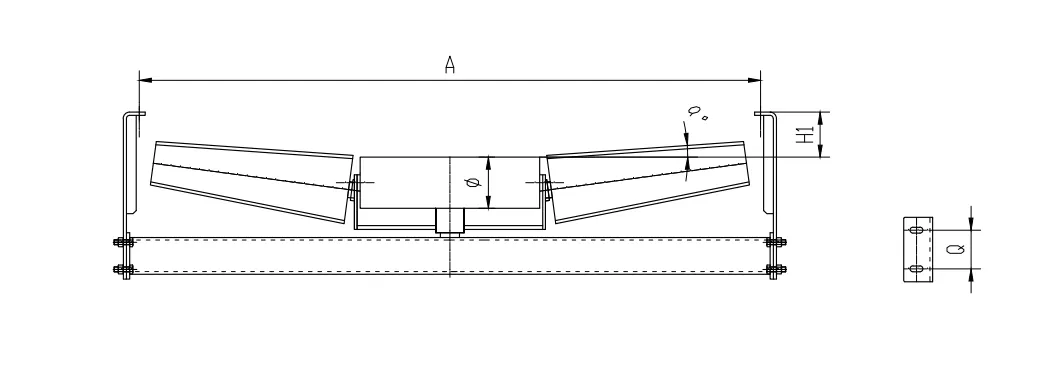

Troughing idlers are cylindrical rollers positioned at intervals along a conveyor belt. They are typically set at an angle, forming a trough-like shape that helps to cradle the belt and the materials it carries. The primary function of these idlers is to support the conveyor belt, ensuring that it maintains its shape and that materials remain contained during transport. This design minimizes spillage and enhances the efficiency of material handling processes.

The Importance of Troughing Idlers

1. Load Distribution Troughing idlers facilitate even load distribution along the conveyor belt. By providing support at multiple points, they help in reducing stress on the belt, thus extending its lifespan. Uneven weight distribution can lead to wear and tear or even conveyor failure.

2. Material Containment The trough shape created by idlers prevents spillage of materials during transport. This containment not only reduces losses but also minimizes the risk of accidents and environmental hazards associated with material spillage.

3. Reduction of Friction Properly designed and maintained troughing idlers contribute to the reduction of friction between the conveyor belt and roller surfaces. Lower friction means less energy is consumed in moving the materials, resulting in more efficient operation and lower operational costs.

4. Versatility Troughing idlers come in various designs and sizes, making them adaptable to different types of materials and conveyor configurations. Whether the materials are heavy, light, abrasive, or fragile, there's a suitable troughing idler available to meet specific needs.

Types of Troughing Idlers

Troughing idlers can be categorized based on their configuration and design

. The most common types include- Standard Troughing Idlers These are typically set at 20°, 35°, or 45° angles, providing reliable support for a wide range of materials.

troughing idlers manufacturer

- Garland Idlers Used in applications involving heavy loads, these idlers consist of a series of rolls that help in maintaining the belt trajectory while offering increased support.

- Return Idlers Designed to support the return run of the conveyor belt, return idlers ensure that the belt remains aligned while minimizing wear.

- Impact Idlers Located at loading points, these idlers are reinforced to absorb the impact of falling materials, protecting the belt from damage.

Selecting the Right Manufacturer

Choosing the right troughing idler manufacturer is critical for ensuring optimal performance and reliability. When evaluating manufacturers, consider the following factors

- Quality Look for manufacturers that adhere to international quality standards and use durable materials in their products. High-quality idlers will have better resistance to wear, corrosion, and overall environmental stressors.

- Customization A reputable manufacturer should offer customizable options to meet specific operational needs. Whether it's a unique size, load capacity, or material type, customization can enhance the efficiency of your conveyor system.

- Technical Expertise Manufacturers with a strong background in engineering and technical expertise can provide valuable insights and support in selecting the right idlers for your system.

- After-Sales Support Reliable after-sales service is essential for addressing any issues that may arise post-installation. A good manufacturer will offer warranties, maintenance guidance, and readily available support.

Conclusion

Troughing idlers are a fundamental component of conveyor systems, essential for efficient material handling. Understanding their function, types, and the importance of selecting a reputable manufacturer can significantly impact the performance and longevity of your conveyor operations. As industries continue to evolve and the demand for efficient material handling solutions grows, the role of troughing idlers will remain pivotal, underpinning the effectiveness of conveyor systems across diverse applications. Investing in quality troughing idlers and partnering with experienced manufacturers can yield significant returns in terms of efficiency, safety, and cost-effectiveness in the long run.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025