Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu take-up pulley

Understanding Take-Up Pulleys Essential Components in Mechanical Systems

Take-up pulleys are essential components in various mechanical systems, particularly in conveyors, cable systems, and other machinery that utilizes belts or cables to transfer power or materials. Their primary function is to maintain the required tension in these systems, ensuring smooth operation, reducing wear and tear, and enhancing overall efficiency. In this article, we will explore the significance of take-up pulleys, their design, applications, and maintenance considerations.

What is a Take-Up Pulley?

A take-up pulley is a type of pulley that accommodates the adjustment of tension in a belt or cable system. It is designed to take up slack in the belt or cable, which can occur due to wear, stretching, or temperature variations. The take-up pulley is typically mounted on a frame that can be moved to adjust the position of the pulley, thereby regulating the tension in the belt or cable.

Importance of Take-Up Pulleys

In any belt-driven system, maintaining the correct tension is crucial for several reasons

1. Efficiency and Performance The right amount of tension ensures that the belt or cable can effectively transfer power without slipping. This maximizes the efficiency of the system and improves performance.

2. Wear Reduction Excessive slack can cause the belt to rub against adjacent components, leading to increased wear and a shorter lifespan for both the belt and the machinery. A properly tensioned system minimizes friction and wear.

3. Safety Overly loose belts can slip, while overly tight belts can cause undue stress on components, leading to potential failures. Proper tension management enhances safety in mechanical operations.

4. Noise Reduction Systems that operate under proper tension generate less noise and vibration, leading to a more comfortable working environment.

Design Considerations

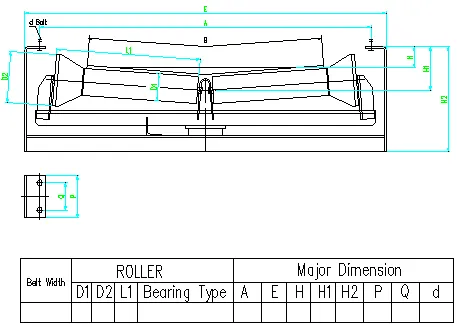

Take-up pulleys come in various designs, depending on the specific application. Some key design features include

- Adjustability Most take-up pulleys can be adjusted vertically or horizontally to accommodate the required tension. This can be done manually or through automated systems.

take-up pulley

- Materials The materials used for take-up pulleys must withstand the operational conditions, including load, speed, and environmental factors

. Common materials include steel, aluminum, and reinforced plastics.- Belt or Cable Compatibility Different applications require specific types of belts or cables. Take-up pulleys are designed to work with a variety of belt or cable types, including flat belts, V-belts, and chain systems.

Applications

Take-up pulleys are widely used across numerous industries. Some common applications include

- Conveyor Systems In warehouses and manufacturing plants, take-up pulleys are vital for maintaining belt tension in conveyor systems that transport goods and materials.

- Mining and Quarrying Heavy-duty take-up pulleys are employed in mining operations to handle massive loads and transfer materials efficiently.

- Textile Industry In textile manufacturing, take-up pulleys play a role in loom and spinning machines, where consistent tension is crucial for product quality.

- Elevators and Escalators In vertical transport systems, take-up pulleys help manage the tension in cables, ensuring safe and smooth operation.

Maintenance Considerations

Proper maintenance of take-up pulleys is essential to ensure their longevity and efficient performance. Regular inspections should be conducted to check for wear, alignment, and lubrication. Additionally, operators should be aware of any unusual noises or vibrations, as these can indicate potential issues with the pulley system.

Conclusion

Take-up pulleys are indispensable components in modern mechanical systems. They play a critical role in ensuring that belts and cables operate efficiently, safely, and with minimal wear. By understanding their importance, design, applications, and maintenance, operators can enhance the longevity and performance of their machinery, ultimately leading to more efficient industrial processes.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025