Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu កុម្ភៈ . 10, 2025 21:56

Back to list

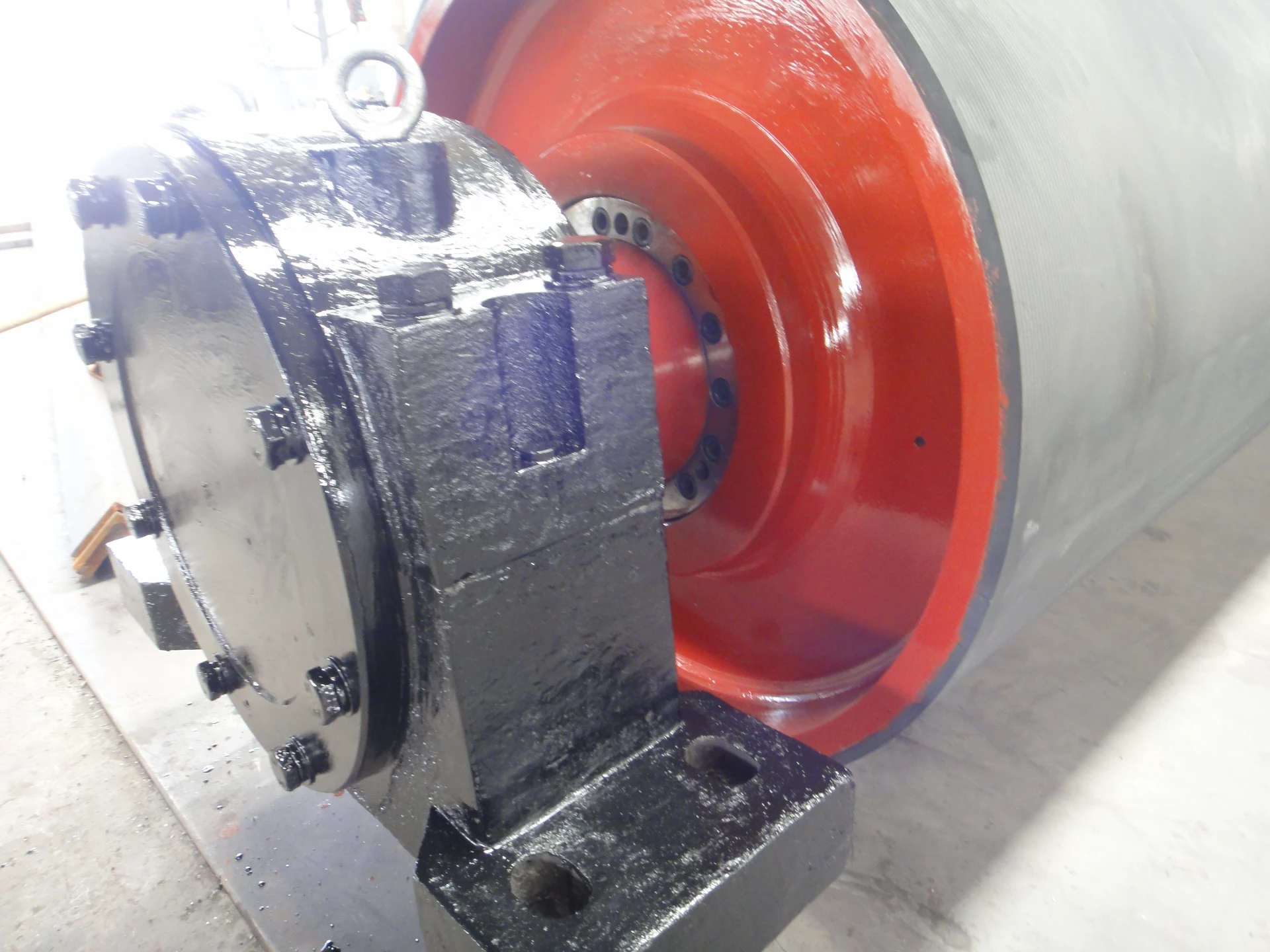

Bend Pulley (Non-driving Pulley)

Understanding the crucial role of a tail pulley in the anatomy of a conveyor system is vital for anyone involved in materials handling or industrial operations. A tail pulley, typically mounted at the tail end of a conveyor belt, is a core component that significantly influences the efficiency, reliability, and lifespan of the conveyor system.

The pivoting nature of tail pulleys aids in the automatic tensioning of the conveyor belt. This automatic adjustment capability compensates for belt stretch and other operational loads, minimizing manual intervention and ensuring that the system runs smoothly. This not only boosts productivity but also enhances safety by reducing the risk of belt-related malfunctions that could lead to workplace accidents. In industries dealing with bulk material handling, the reliability of a conveyor system can significantly impact operational throughput. The tail pulley, despite being a smaller component, plays a critical role in the smooth running of the conveyor system. Regular inspections and maintenance are, therefore, key to extending the life of a tail pulley. It is recommended to check for signs of wear, alignment issues, and potential material build-up, ensuring the system remains efficient and reliable. Various authoritative bodies provide detailed standards and guidelines on the specification and maintenance of tail pulleys. Adhering to these standards not only guarantees operational safety but also enhances trustworthiness and credibility amongst stakeholders and clients. Compliance with international standards also positions businesses favorably in a competitive marketplace, demonstrating a commitment to quality and safety. Consulting with experts in conveyor systems is invaluable when selecting and maintaining tail pulleys. Professionals possess the expertise to guide decisions based on specific industrial needs and conditions, ultimately improving system performance and reducing long-term costs. This collaborative approach ensures that businesses can capitalize on the latest technological advancements and industry insights, keeping operations at the forefront of efficiency and effectiveness. In conclusion, while the tail pulley might seem like a minor part of a conveyor system, its impact on operational efficiency cannot be understated. By carefully selecting the appropriate type, maintaining it scrupulously, and adhering to industry standards, businesses will be well-equipped to maximize their material handling capabilities, ensuring a competitive edge in their respective fields.

The pivoting nature of tail pulleys aids in the automatic tensioning of the conveyor belt. This automatic adjustment capability compensates for belt stretch and other operational loads, minimizing manual intervention and ensuring that the system runs smoothly. This not only boosts productivity but also enhances safety by reducing the risk of belt-related malfunctions that could lead to workplace accidents. In industries dealing with bulk material handling, the reliability of a conveyor system can significantly impact operational throughput. The tail pulley, despite being a smaller component, plays a critical role in the smooth running of the conveyor system. Regular inspections and maintenance are, therefore, key to extending the life of a tail pulley. It is recommended to check for signs of wear, alignment issues, and potential material build-up, ensuring the system remains efficient and reliable. Various authoritative bodies provide detailed standards and guidelines on the specification and maintenance of tail pulleys. Adhering to these standards not only guarantees operational safety but also enhances trustworthiness and credibility amongst stakeholders and clients. Compliance with international standards also positions businesses favorably in a competitive marketplace, demonstrating a commitment to quality and safety. Consulting with experts in conveyor systems is invaluable when selecting and maintaining tail pulleys. Professionals possess the expertise to guide decisions based on specific industrial needs and conditions, ultimately improving system performance and reducing long-term costs. This collaborative approach ensures that businesses can capitalize on the latest technological advancements and industry insights, keeping operations at the forefront of efficiency and effectiveness. In conclusion, while the tail pulley might seem like a minor part of a conveyor system, its impact on operational efficiency cannot be understated. By carefully selecting the appropriate type, maintaining it scrupulously, and adhering to industry standards, businesses will be well-equipped to maximize their material handling capabilities, ensuring a competitive edge in their respective fields.

Latest news

-

The Unrivaled Performance of Polyurethane Pulleys in Industrial ApplicationsNewsAug.25,2025

-

The Critical Role of Drum Lagging in Conveyor SystemsNewsAug.25,2025

-

Navigating Industrial Efficiency: The Critical Role of Conveyor PulleysNewsAug.25,2025

-

InIntroduction to Advanced Pulley Lagging SolutionsNewsAug.25,2025

-

Industry Trends in Pulley Lagging TechnologyNewsAug.25,2025

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

OUR PRODUCTS