Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu superior conveyor parts

Understanding Superior Conveyor Parts Enhancing Efficiency in Material Handling

In today's fast-paced industrial landscape, efficiency and reliability are paramount. One of the unsung heroes of modern manufacturing and logistics is the conveyor system. At the heart of these systems are superior conveyor parts, which play a vital role in ensuring smooth operations. This article will explore the significance of high-quality conveyor components, their various types, and how they contribute to overall productivity.

The Importance of Quality Conveyor Parts

Conveyor systems are essential for transporting materials across various sectors, including manufacturing, warehousing, and distribution. The efficiency of these systems largely depends on the quality of their components. Superior conveyor parts minimize downtime, reduce maintenance costs, and enhance the reliability of operations. Conversely, subpar components can lead to frequent breakdowns, affecting the entire supply chain and ultimately impacting the bottom line.

Investing in high-quality conveyor parts can yield substantial long-term savings. Durable components often require less frequent replacement, ensuring that production lines remain operational with minimal interruptions. Moreover, high-caliber materials can withstand the rigors of heavy use, making them ideal for high-capacity environments.

Types of Superior Conveyor Parts

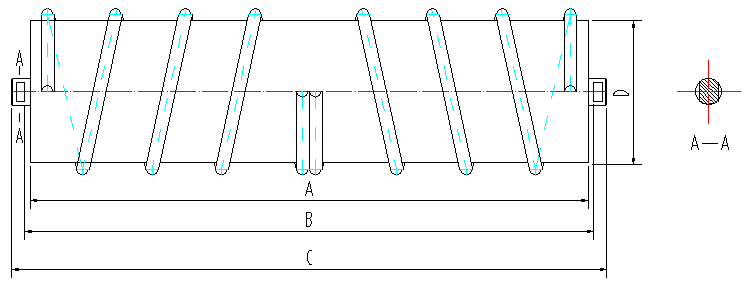

1. Belts and Rollers The belt is the primary moving part of a conveyor system, and its material and design impact performance significantly. Superior belts are constructed from durable materials that resist wear and tear. Rollers, which support the belt, come in various types, including idler rollers, drive rollers, and return rollers. High-quality rollers ensure smooth movement and minimize friction, enhancing overall efficiency.

2. Motors and Drives The motor is the powerhouse of a conveyor system, converting electrical energy into mechanical energy. Superior motors are designed for reliability and energy efficiency, offering optimal power for various conveyor applications. Coupled with quality drive systems, including gearboxes and pulleys, they ensure that the conveyor operates seamlessly, even under heavy loads.

3. Guides and Supports These components help direct the materials being transported and maintain the proper alignment of the conveyor belt. Superior guides and supports are engineered to reduce friction and wear, promote efficient movement, and enhance the overall lifespan of the conveyor system.

superior conveyor parts

4. Sensors and Control Systems Advanced conveyor systems often incorporate sensors and control systems that monitor performance and automate operations. High-quality sensors can detect changes in load, speed, and position, enabling real-time adjustments that prevent issues before they escalate. These technologies contribute to improved safety and operational efficiency.

5. Frames and Structures The structural integrity of a conveyor system is reliant on the quality of its framework. Superior conveyor frames are built from robust materials, offering strength and stability to handle heavy loads. A well-constructed frame not only supports the conveyor's weight but also enhances its durability and lifespan.

Benefits of Using Superior Conveyor Parts

1. Increased Productivity High-quality components contribute to a more efficient material handling process. With fewer breakdowns and maintenance needs, operations can run smoothly, reducing downtime and increasing overall productivity.

2. Cost Efficiency Although superior conveyor parts may involve a higher upfront investment, they generate significant cost savings in the long run. Reduced repairs, replacements, and maintenance costs can lead to a more favorable return on investment.

3. Enhanced Safety Quality components improve the overall reliability of conveyor systems, reducing the risk of accidents and injuries in the workplace. Safety features embedded in advanced components, such as emergency stops and overload sensors, further mitigate risks.

4. Scalability and Adaptability Superior conveyor parts are designed to be versatile, allowing for customization and scaling as business needs change. This adaptability is crucial for companies that aim to expand their operations or introduce new products.

Conclusion

In summary, superior conveyor parts are integral to the efficiency and reliability of modern conveyor systems. By investing in high-quality components, businesses can boost productivity, reduce operational costs, and enhance safety. In an ever-competitive market, ensuring that your conveyor system is equipped with the best parts is not just a choice but a strategic necessity. Embracing superior conveyor parts will ultimately lead to greater efficiency and operational success, helping companies thrive in the dynamic world of material handling.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025