Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

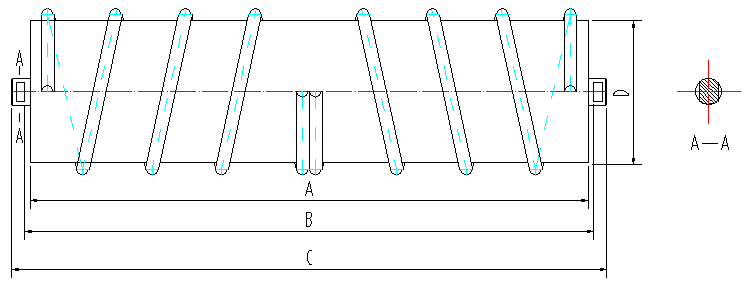

Zulu Spiral Return Idler for Optimized Conveyor Performance and Efficiency

Understanding the Spiral Return Idler A Key Component in Conveyor Systems

In the world of material handling and conveyor systems, the efficiency and reliability of machinery are paramount. One crucial component that plays a significant role in enhancing the operational efficacy of these systems is the spiral return idler. This specialized part is engineered to ensure that conveyor belts operate smoothly, minimizing wear and tear while maximizing productivity.

What is a Spiral Return Idler?

A spiral return idler is a type of idler roller that is designed with a unique spiral pattern. Unlike traditional flat or crowned idlers, the spiral design allows for better belt tracking and reduced friction. This idler is typically installed on the return side of a conveyor belt, which is the section that moves unequipped material back to the loading point. The primary purpose of this idler is to support the return journey of the conveyor belt while maintaining its alignment and preventing undue stress on the belt's structure.

The Importance of Proper Alignment

Proper alignment of the conveyor belt is crucial for the longevity of the equipment and the safety of operations. Misalignment can lead to several issues, including increased wear on the belt, greater energy consumption, and a higher risk of material spillage. The spiral return idler addresses these challenges by its design, which helps to center and stabilize the belt as it returns to the top load point. This stabilizing effect ultimately reduces the risk of misalignment and contributes to smoother operation.

Benefits of Spiral Return Idlers

1. Enhanced Tracking The spiral design of the idler helps maintain the belt’s position, which is critical for preventing slippage and keeping materials contained within the conveyor system.

spiral return idler

2. Reduction in Maintenance Costs With better alignment and tracking, there is less wear on the belt and other associated components of the conveyor system. This reduction in wear translates to lower maintenance costs and fewer disruptions in operations.

3. Improved Material Flow The design of the spiral return idler encourages better flow of materials. This is particularly important in industries such as mining, agriculture, and logistics where bulk materials need to be handled efficiently.

4. Energy Efficiency When the conveyor belt operates smoothly with minimal friction, it consumes less energy. Improved energy efficiency is not only cost-effective but also environmentally friendly.

5. Versatility in Application Spiral return idlers can be used in various applications, from heavy-duty industrial settings to more delicate operations, making them a versatile choice for many businesses.

Conclusion

The spiral return idler is more than just a piece of equipment in conveyor systems; it serves as a vital component that enhances efficiency, safety, and reliability. As industries strive to optimize their operations, understanding the functionality and benefits of such components becomes increasingly important.

Incorporating spiral return idlers into conveyor systems is an investment in the future of material handling. Their design not only supports improved belt performance but also contributes to an overall reduction in the total cost of ownership for conveyor equipment. As technology continues to advance, the development and refinement of components like the spiral return idler will undoubtedly play a pivotal role in the evolution of material handling solutions. For any business involved in moving bulk materials, considering such innovations can lead to significant operational advantages and foster long-term success.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025